Pure-grain solid-state liquor brewing process

A solid liquor and process technology, which is applied in the fields of food processing and alcoholic beverages, can solve the problems of rising prices, high acidity of mother distiller's grains, high amylose content, etc., and achieve the effects of reducing industrial costs, improving utilization efficiency, and solving sticking and caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Adopting the method of the invention to brew pure grain solid liquor is specifically a non-first-round brewing process under continuous brewing production.

[0021] Step S1, material preparation

[0022] Select high-quality japonica sorghum and waxy wheat, wash and remove impurities, and mix evenly according to the ratio (see Table 1) for later use. Japonica sorghum and waxy wheat are both processed as whole grains without crushing.

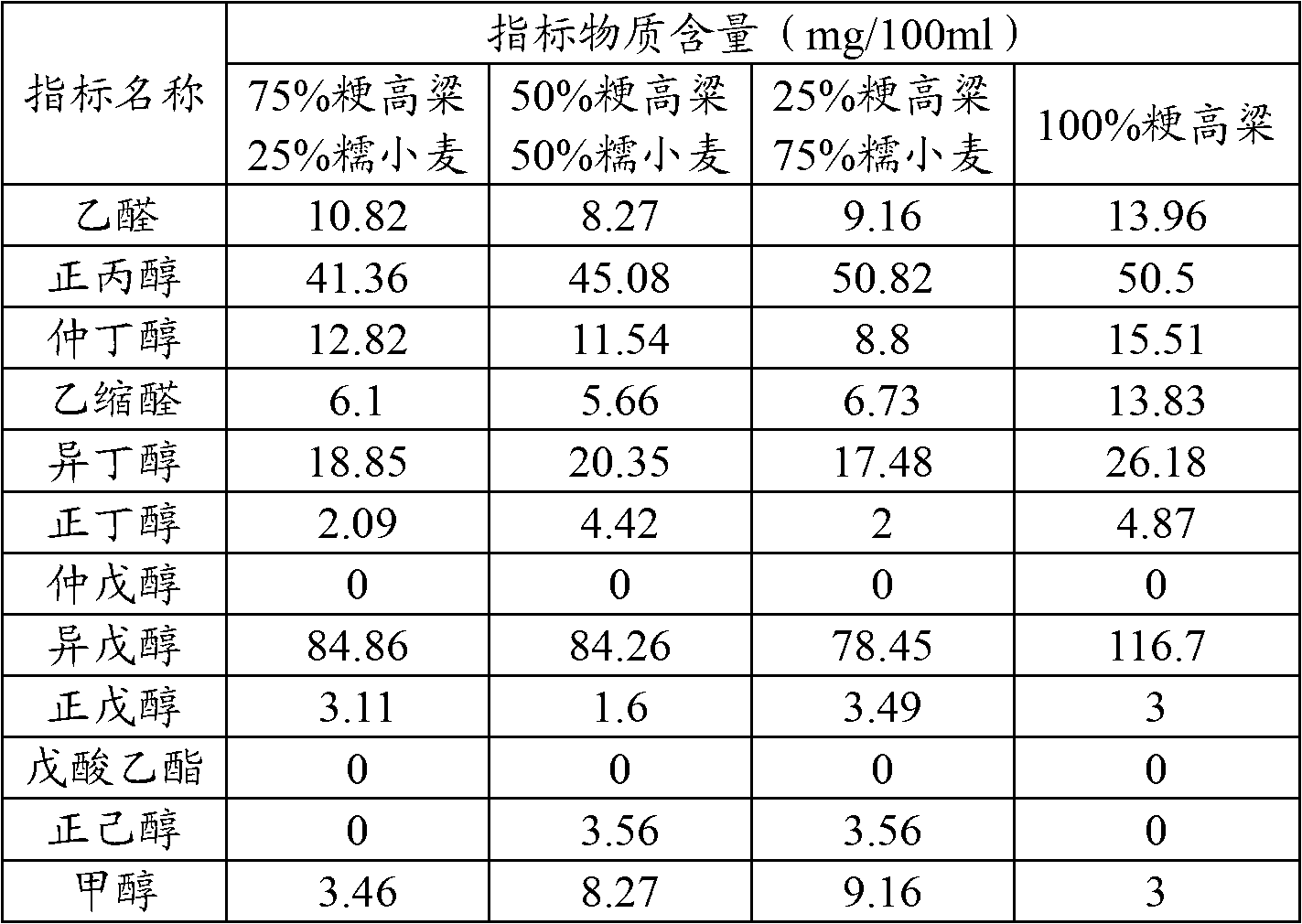

[0023] Table 1 Ingredients of Liquor Brewing Raw Materials

[0024]

[0025] Prepare the rice bran husk and the waste from the last round of brewing as a bulking agent. The amount of rice bran husk is 7% to 9% of the total weight of grain raw materials, and the amount of discarded grains is 16% to 20% of the total weight of grain raw materials.

[0026] Step S2, soaking grain

[0027] Put the raw grains prepared in step S1 into the grain soaking container, and add water until the level of the raw grains is 23 cm to 26 cm above the l...

Embodiment 2

[0047] Adopt the method of the present invention to brew pure grain solid liquor, and its similarities with Example 1 will not be repeated. The difference lies in the amount of bulking agent prepared in the step S1 material preparation process, the amount and temperature condition of the bulking agent in the step S4 saccharification process. .

[0048] Step S1, material preparation

[0049] Prepare the rice bran husk and the waste from the last round of brewing as a bulking agent. The consumption of rice bran husk is 8% of the total weight of grain raw materials, and the consumption of discarded grains is 18% of the total weight of grain raw materials.

[0050] Step S4, saccharification

[0051] The first step of mixing koji: the amount of rice bran husk is 3.5% of the total weight of the raw material grain; the amount of discarded grains is 9% of the total weight of the raw material grain; Clinker liquor koji medicine.

[0052] The second step of mixing koji: the amount o...

Embodiment 3

[0054] The method of the present invention is used to brew pure grain solid liquor. The same parts as those in Example 1 or 2 will not be repeated. The difference lies in the temperature conditions of the saccharification system in the saccharification step S4.

[0055] During the saccharification process, the temperature in the saccharification system is maintained at 37°C to 39°C, and the more optimal temperature is 38°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com