Connection rod type fixed-point feeding system

A feeding system and link-type technology, which is applied in the field of link-type fixed-point feeding system, can solve the problems that affect the efficiency of wine production and brewing quality, can not be replenished in time, and the auxiliary time is long, so as to improve the efficiency of wine production and save time. , The effect of uniform and smooth discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

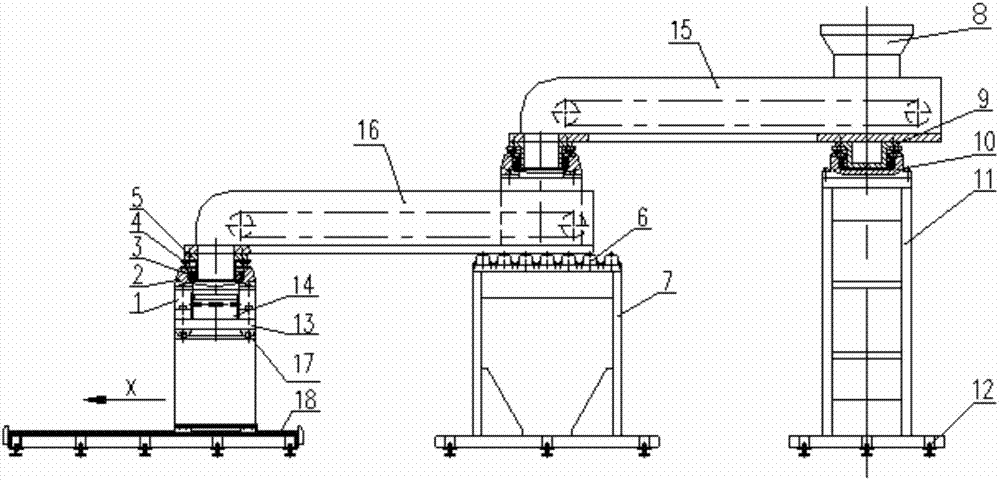

[0029] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

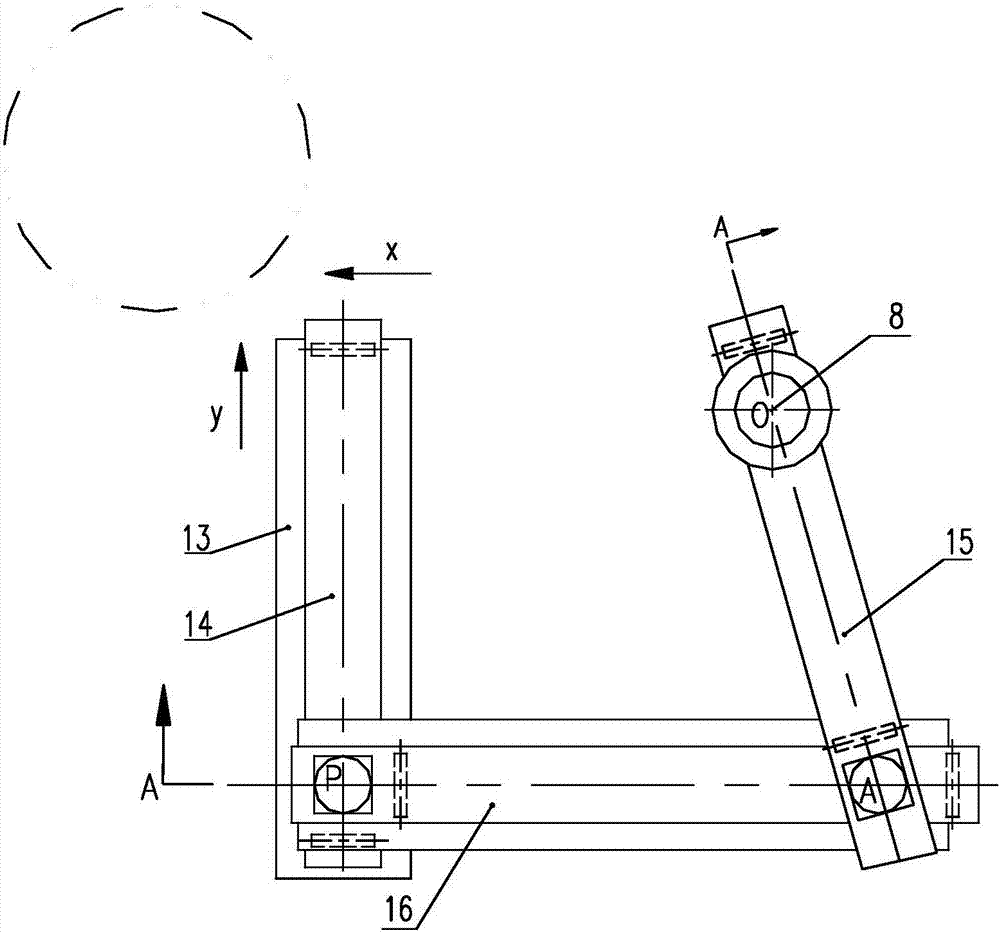

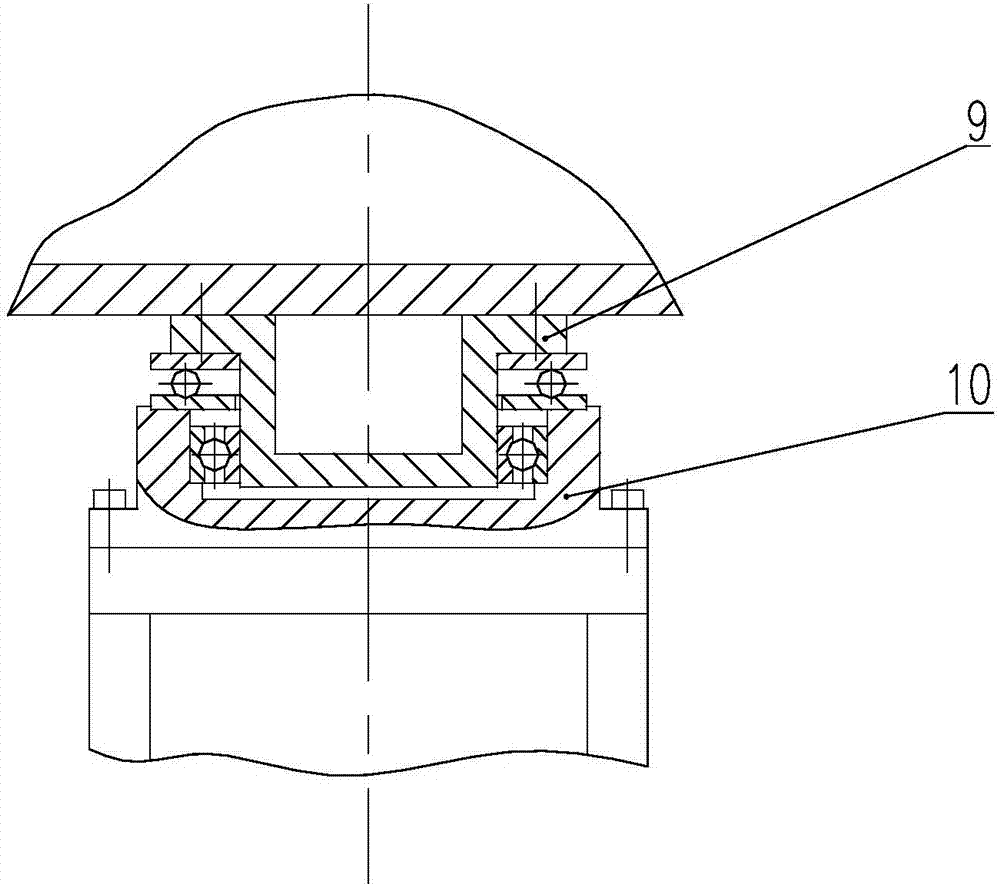

[0030] Such as figure 1 , 2 Shown, a link type fixed-point feeding system, it includes:

[0031] The first supporting frame 11;

[0032] Telescopic arm 13;

[0033] Telescopic arm moving mechanism, the telescopic arm moving mechanism is connected with the telescopic arm 13, so that the telescopic arm moving mechanism drives the telescopic arm 13 to move;

[0034] Follow-up conveyor 14, described follow-up conveyor 14 is installed on the telescopic arm;

[0035] An intermediate conveyor 16, one end of the intermediate conveyor 16 is hinged to the follower conveyor 14 through a hinge mechanism to form a follower joint point P;

[0036] A fixed-axis swing conveyor 15, one end of the fixed-axis swing conveyor 15 is hinged to the other end of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com