Steam power energy-saving water supply device for wine brewing

A technology of steam power and water supply, applied in the field of brewing, which can solve the problems of unfavorable economic development goals, large brewing projects, and large power consumption, and achieve the effects of wide injection range, reduced CO2 concentration, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

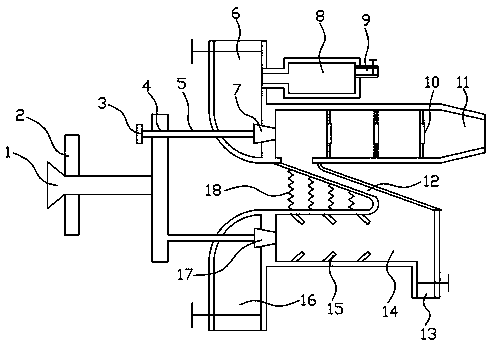

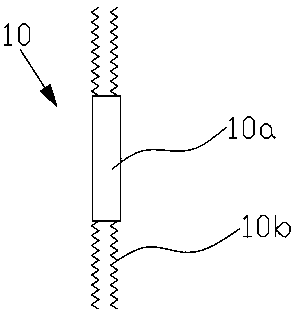

[0018] Such as Figure 1~3 As shown, the steam power energy-saving water supply device for brewing includes a steam inlet 6, the lower end of the steam inlet 6 is connected to a jet chamber 11, the left side of the bottom of the jet chamber 11 is connected to a water storage tank 14 through a water supply chamber 12, and the left side of the water storage tank 14 is connected to a water supply The mouth 16 and the inside of the jet chamber 11 are evenly distributed with elastic plate mechanisms 10, the jet chamber 11 is a cylinder, and the jet outlet of the jet chamber 11 is in the shape of a circular frustum transparent up and down. The water supply device of the present invention uses steam as the power source to drive the water body, which not only saves the use of electric energy, but also recycles a large amount of steam generated in the brewing process, realizes the environmental protection and reuse of resources, and is conducive to sustainable economic development. In ...

Embodiment 2

[0025] This embodiment is a further optimization scheme based on Example 1: the elastic plate 10a is made of rubber material, and the preferred preparation method of the rubber material is: add 35 parts of silicone rubber and 8 parts of reinforcing filler to the open mill agent and 3.5 parts of structure control agent, after the material is completely eaten, thin pass, and the sheet is released to obtain mixed silicone rubber; add 51 parts of fluororubber, 0.03 part of compatibilizer on the open mill, and then add 1.7 parts of acid absorbing agent and 10 parts of reinforcing filler, mixed evenly, covered with rolls, to obtain mixed fluororubber; gradually added the prepared mixed silicone rubber to the mixed fluororubber, and then added 0.8 part of vulcanizing agent and 0.52 part of crosslinking aid , mixed evenly, and a blend of fluororubber and silicone rubber was prepared; the blend of fluororubber and silicone rubber was vulcanized by an electric heating oil pressure plate ...

Embodiment 3

[0028] Such as Figure 1~3 As shown, the steam power energy-saving water supply device for brewing, its working principle is: adjust the position of the nut 3 on the screw 5, so that the threaded hole 4 and the screw 5 have an appropriate relative displacement distance, pull the power rod 1 to the left to make the water supply piston 17 Leaving the valve hole, the supply water enters from the water supply port 16, and enters the jet chamber 11 along the water supply chamber 12, and continues to pull the power rod 1 to the left. When the power rod 1 reaches the nut 3, it drives the steam piston 7 to leave the valve hole, and the steam flows from The steam inlet 6 is injected, the air is injected from the air inlet 9, and the steam carries the air into the jet cavity 11, so that the supply water inside the jet cavity 11 is ejected out of the jet cavity 11 at high speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com