Noise reduction floor under vacuum cleaner motor box

A vacuum motor and vacuum cleaner technology, applied in vacuum cleaners, electrical components, electromechanical devices, etc., can solve problems such as noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

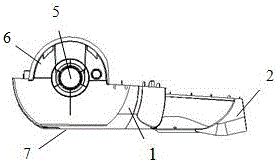

[0037] Figure 4 It is a top view structure schematic diagram of the bottom shell of the vacuum cleaner in the present invention, Figure 5 It is a schematic view of the bottom shell of the vacuum cleaner in the present invention, Figure 6 It is a side view structure schematic diagram of the bottom shell of the vacuum cleaner in the present invention.

[0038] As shown in the figure, the front end of the bottom shell 1 of the horizontal vacuum cleaner with the structural features of the present invention is provided with a connector 2 connected to the dust suction hose and connected to the dust collection device. The caster frame hole 4 is used to install the caster frame (not shown).

[0039] Both sides of the rear part of the bottom case 1 are respectively formed with a rear caster axle frame 5 and a caster baffle 6 correspondingly.

[0040] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com