Cerium-ion-doped gadolinium lutetium oxyfluoride scintillation glass and preparation method thereof

A technology of oxyfluoride and scintillation glass, which is applied in the field of cerium ion-doped gadolinium lutetium oxyfluoride scintillation glass and its preparation, which can solve the problems of easy deliquescence, low density of scintillation glass, and low luminous intensity, and reach the melting and annealing temperature low cost, convenient for industrialized production, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

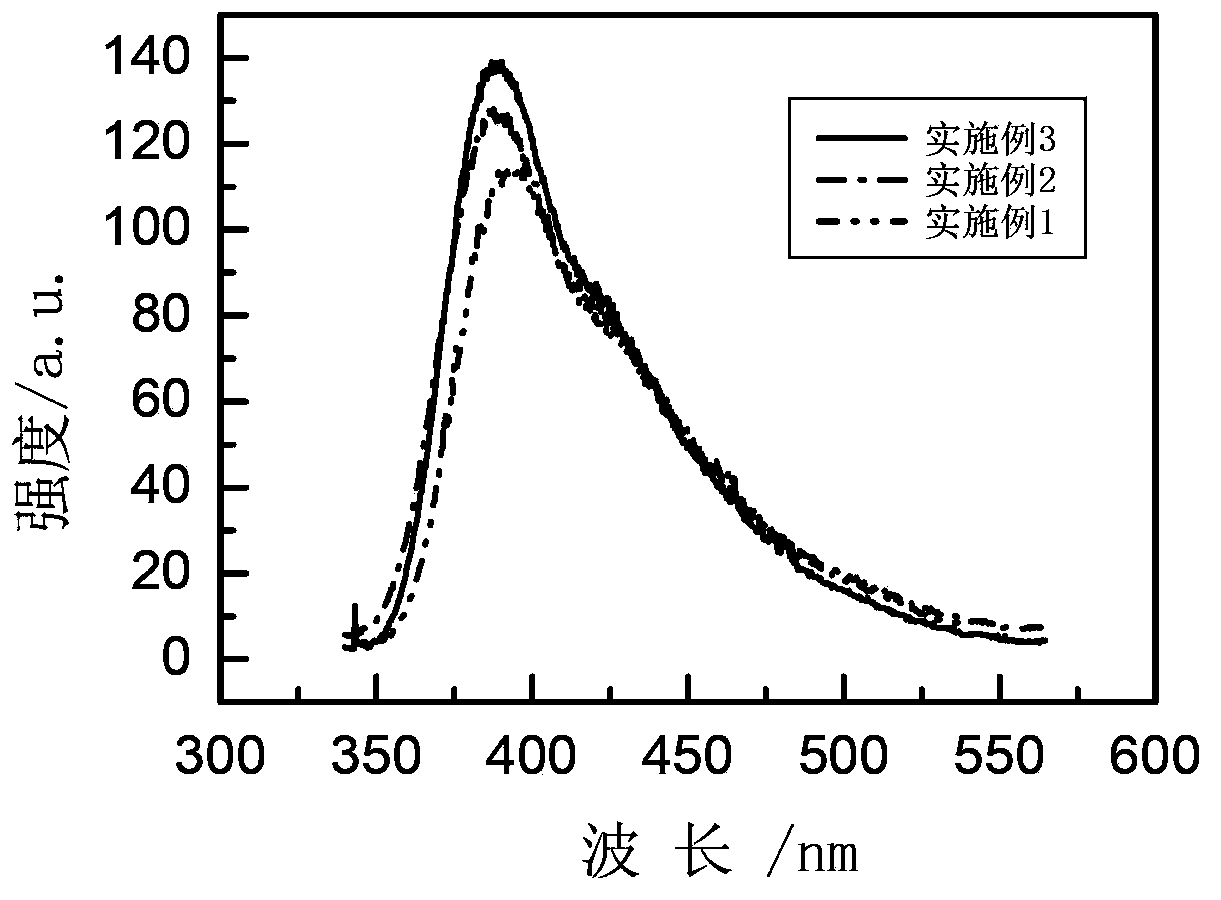

Embodiment 1

[0018] According to raw material composition: SiO 2 : 34 mol%, B 2 o 3 : 15mol%, BaF 2 : 15 mol%, Lu 2 o 3 : 20 mol%, Gd 2 o 3 : 15 mol%, Ce 2 o 3 : 1 mol%, weigh each raw material, mix all raw materials evenly; then pour into a crucible to melt into a melt, the melting temperature is 1350-1450°C, keep it warm for 0.5-2 hours after melting; pour the melt into a preheated On a cast iron mold at 200-300°C, cool naturally to form glass; place the glass in a muffle furnace for annealing, annealing conditions: keep warm at 400-500°C for 1 hour, then cool down to 45-45°C at a rate of 8-10°C / hour 55°C, then turn off the power supply of the muffle furnace and automatically cool down to room temperature to obtain cerium ion-doped gadolinium lutetium oxyfluoride scintillation glass with a density of 6.1g / cm 3 ; The scintillation glass is cut, surface ground, and polished to be processed into a 50 × 50 × 10mm scintillation glass sample, and the scintillation glass sample is exci...

Embodiment 2

[0020] Substantially the same as Example 1, the only difference is the raw material composition: SiO 2 : 29 mol%, B 2 o 3 : 15mol%, BaF 2 : 15 mol%, Lu 2 o 3 : 25 mol%, Gd 2 o 3 : 15 mol%, Ce 2 o 3: 1 mol%, the density of scintillation glass is 6.2g / cm 3 ; The integral luminous intensity is about 8834.

Embodiment 3

[0022] Substantially the same as Example 1, the only difference is the raw material composition: SiO 2 : 23 mol%, B 2 o 3 : 15mol%, BaF 2 : 15 mol%, Lu 2 o 3 : 30 mol%, Gd 2 o 3 : 15 mol%, Ce 2 o 3 : 2 mol%, the density of scintillation glass is 6.4g / cm 3 ; The integral luminous intensity is about 8924.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com