Method for preparing electromagnetic energy harvester using micro-nano processing technology

An energy harvester and micro-nano processing technology, applied in the direction of microstructure technology, technology for producing decorative surface effects, decorative art, etc., can solve the problems of unfavorable large-scale production and processing, low efficiency, limited output voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

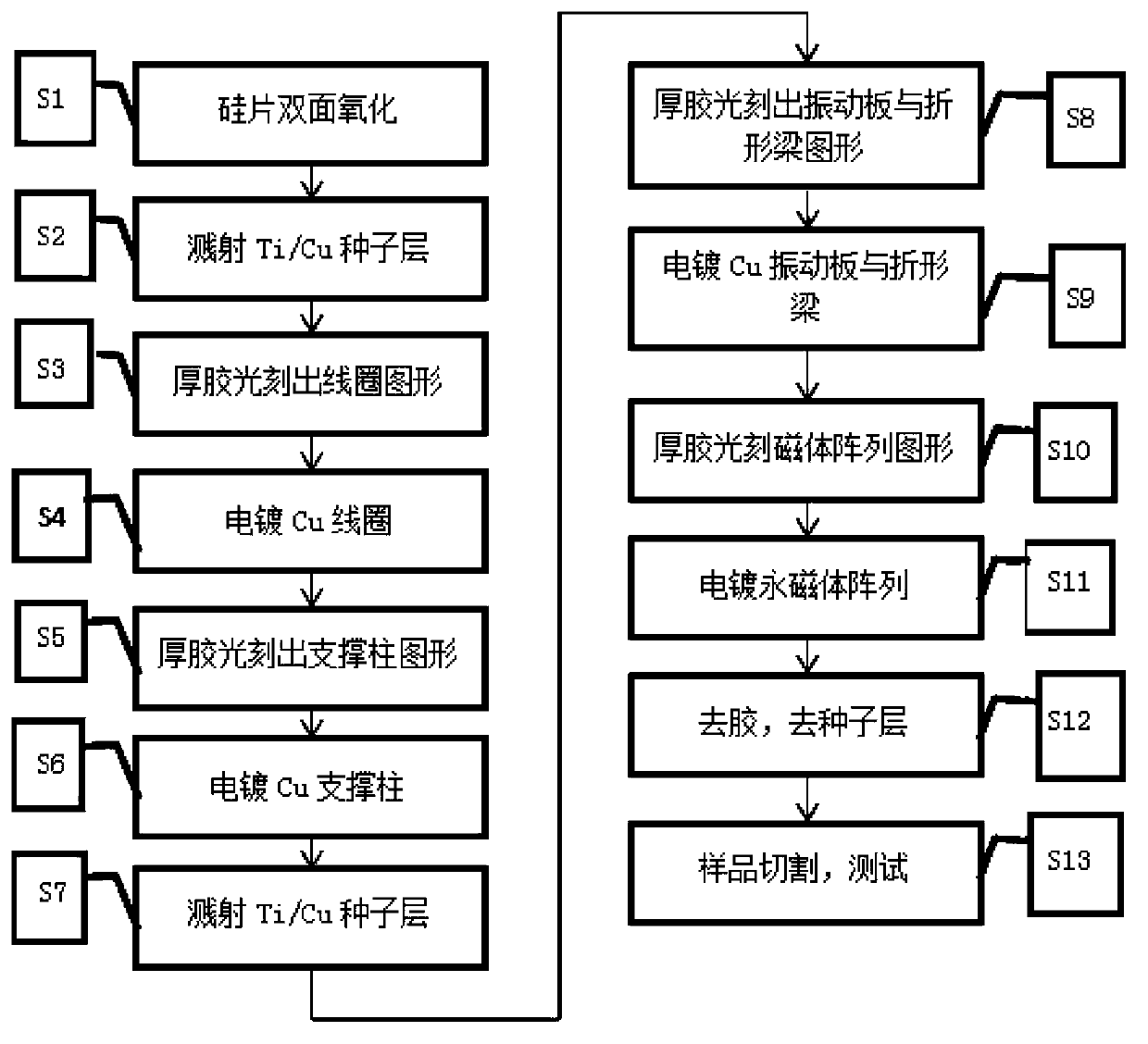

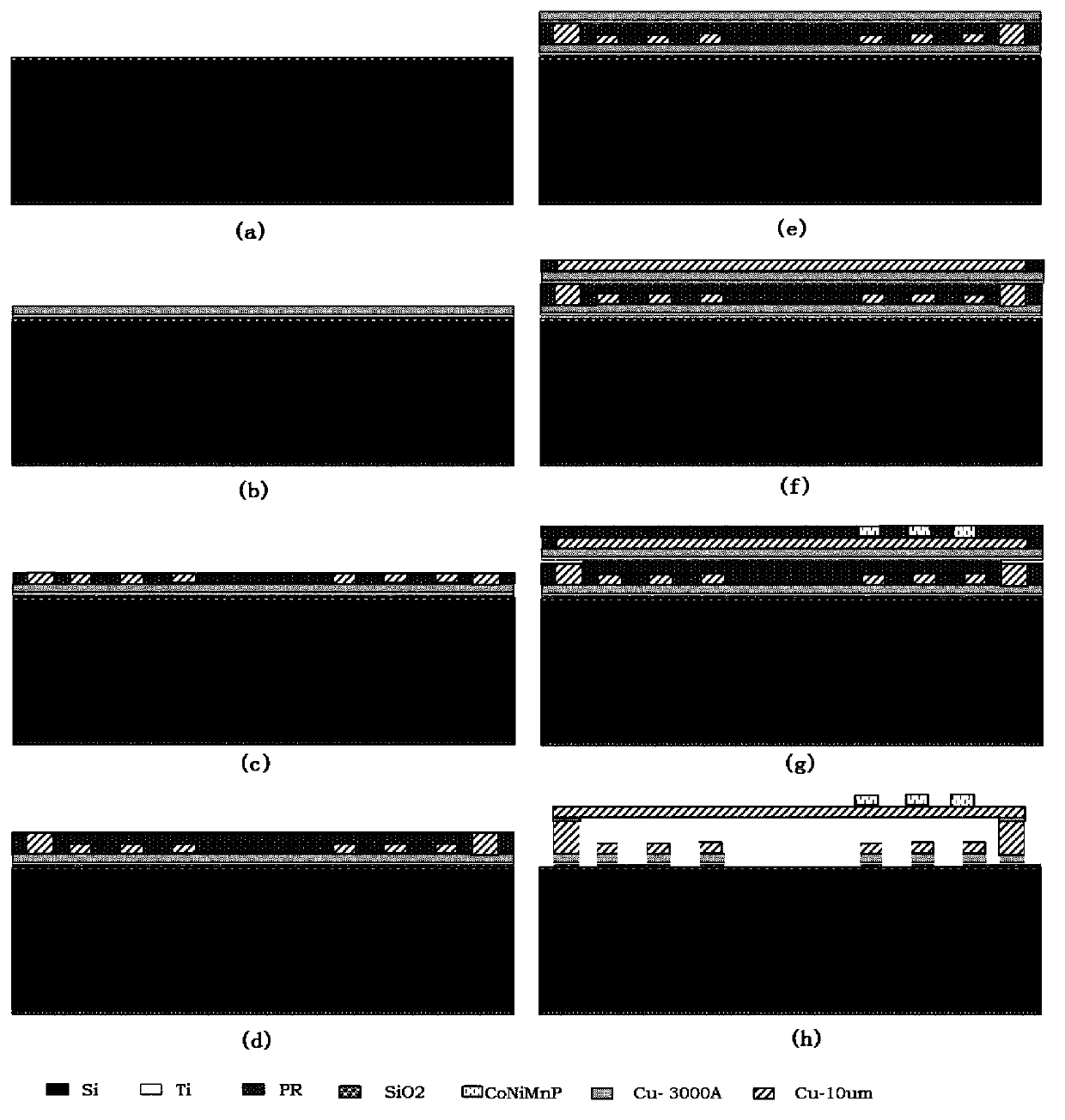

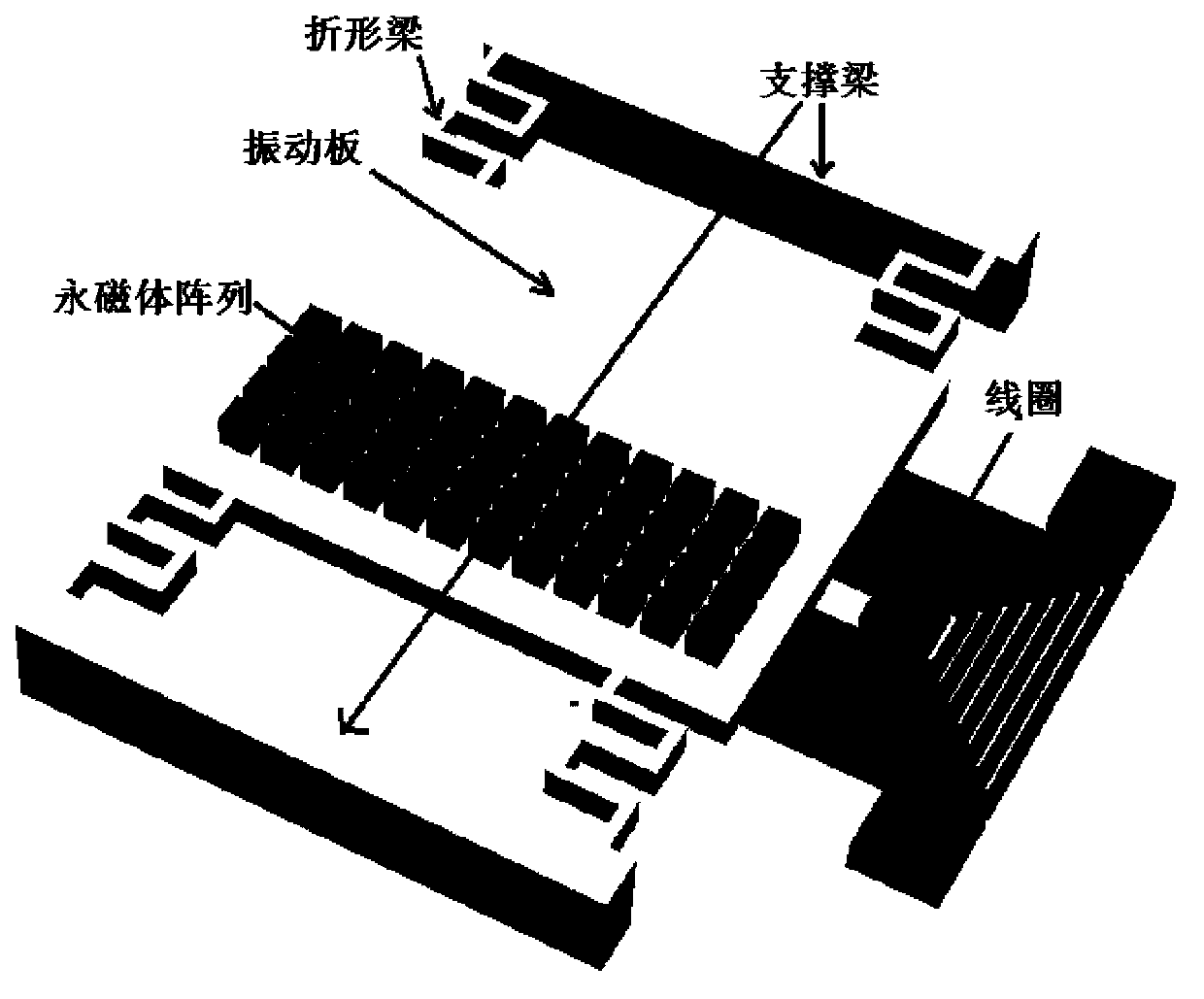

[0053] refer to figure 1 , figure 1 For the step flowchart of the energy harvester that the present invention adopts, comprise the steps:

[0054] Step S1, using double-sided oxidation on a clean (100) crystalline silicon wafer silicon oxide

[0055] Step S2, sputtering metal on a clean (100) silicon wafer by sputtering Metal

[0056] Step S3, drop the photoresist on the surface of the silicon wafer, first pre-level the glue at a speed of 540r / s for 60s, and then perform the formal coating of 1500r / s for 180s to ensure that the photoresist is evenly spread on the surface of the silicon wafer. Dry the film at 100°C for 300s. Expose for 125s under the photolithography machine, then take it out. Then develop and soak in the developer for 30s. Ensure visualization under a microscope. The film was baked at 100°C for 600s.

[0057] Step S4, setting up the electroplating device, adjusting the electroplating current so that the current density is 1ASD, connecting the sili...

Embodiment 2

[0068] refer to figure 1 , figure 1 For the step flowchart of the energy harvester that the present invention adopts, comprise the steps:

[0069] Step S1, using double-sided oxidation on a clean (100) crystalline silicon wafer silicon oxide

[0070] Step S2, sputtering metal on a clean (100) silicon wafer by sputtering Metal

[0071] Step S3, drop the photoresist on the surface of the silicon wafer, first pre-level the glue at a speed of 540r / s for 60s, and then perform the formal coating of 1500r / s for 180s to ensure that the photoresist is evenly spread on the surface of the silicon wafer. Dry the film at 100°C for 300s. Expose for 125s under the photolithography machine, then take it out. Then develop and soak in the developer for 30s. Ensure visualization under a microscope. The film was baked at 100°C for 600s.

[0072] Step S4, setting up the electroplating device, adjusting the electroplating current so that the current density is 1ASD, connecting the sili...

Embodiment 3

[0083] refer to figure 1 , figure 1 For the step flowchart of the energy harvester that the present invention adopts, comprise the steps:

[0084] Step S1, using double-sided oxidation on a clean (100) crystalline silicon wafer silicon oxide

[0085] Step S2, sputtering metal on a clean (100) silicon wafer by sputtering Metal

[0086] Step S3, drop the photoresist on the surface of the silicon wafer, first pre-level the glue at a speed of 540r / s for 60s, and then perform the formal coating of 1500r / s for 180s to ensure that the photoresist is evenly spread on the surface of the silicon wafer. Dry the film at 100°C for 300s. Expose for 125s under the photolithography machine, then take it out. Then develop and soak in the developer for 30s. Ensure visualization under a microscope. The film was baked at 100°C for 600s.

[0087] Step S4, setting up the electroplating device, adjusting the electroplating current so that the current density is 1ASD, connecting the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com