A composite material board, its preparation method and dump truck compartment

A composite material plate and core material technology, which is applied to chemical instruments and methods, vehicle components, and the upper structure of trucks, can solve the problems of unsatisfactory lightweight effects, reduce carbon dioxide and other exhaust emissions, and improve Excellent operation ability and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

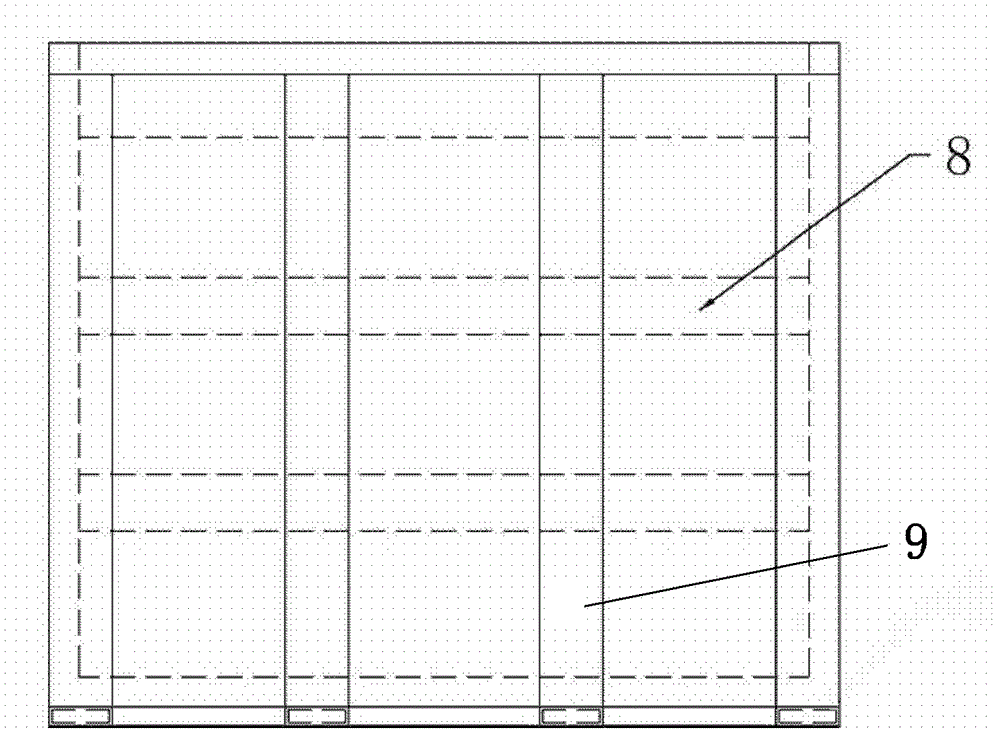

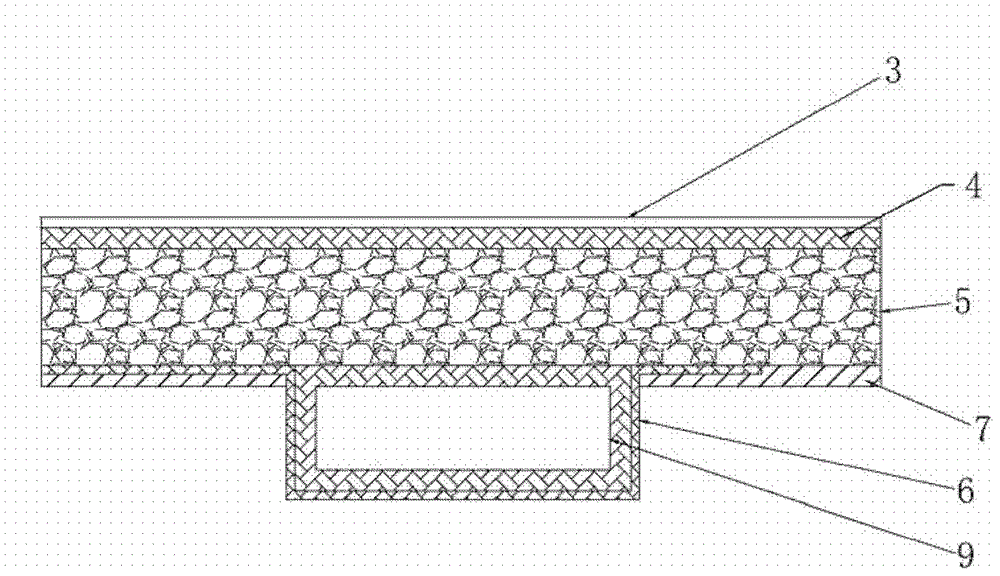

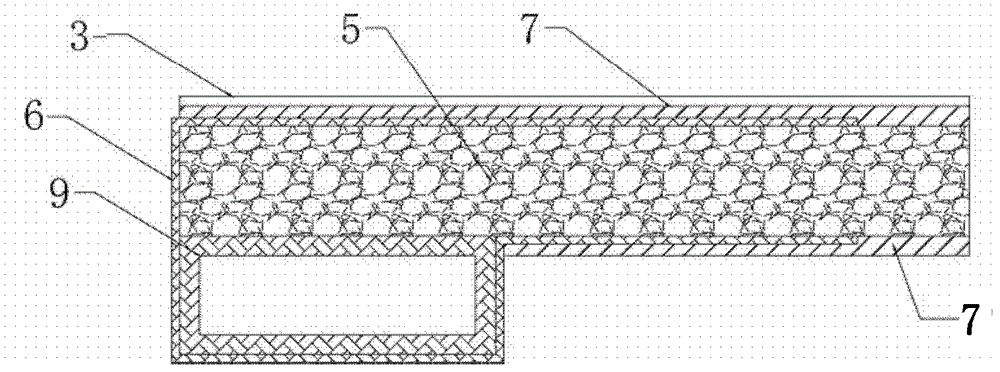

[0044] Example 1 Dump truck compartment containing composite material plate and preparation method thereof

[0045] The following is attached Figure 1-5 The present embodiment will be described in detail.

[0046] (1) Pultrude the 24K large tow carbon fiber and glass fiber fabric according to the required cross-sectional shape to prepare continuous reinforced fiber composite material profiles, and cut them into the specifications required by the carriage;

[0047] (2) polydicyclopentadiene reaction raw material (RIMTEC company, model 2000, consisting of two reaction raw materials A and B) mixed uniformly at a ratio of 1:1, injected into the polydicyclopentadiene shell mold of the plate-shaped car shell assembly through the injection head, and the mold temperature was controlled at 82 ± 2 °C, take out the polydicyclopentadiene shell assembly 3 after the curing is completed.

[0048] (3) Process the integrated molding mold according to the shape of the main body 2 of the ca...

Embodiment 2

[0052] Embodiment 2 Dump truck compartment containing composite material plate and preparation method thereof

[0053] In the present embodiment, prepare the dump truck compartment of the present embodiment in the same way as in Embodiment 1, the difference is that:

[0054] 1. The inner reinforcement beam and the outer reinforcement beam are arranged at an angle of 60° to each other;

[0055] 2. Replace the glass fiber plain weave with aramid fiber twill;

[0056] 3. Use 50% fir and 50% oak as the core material;

[0057] 4. Replace epoxy resin curing system with vinyl resin curing system;

[0058] 5. The thickness of the skin layer covering the external reinforcing beam is 1 / 3 of the overall thickness of the skin layer, and the fiber content of the skin layer is 80%;

[0059] 6. The cross-section shapes of the inner reinforcing beam and the outer reinforcing beam are square and "I" respectively.

Embodiment 3

[0060] Example 3 Dump truck compartment containing composite material plate and preparation method thereof

[0061] In the present embodiment, prepare the dump truck compartment of the present embodiment in the same way as in Embodiment 1, the difference is that:

[0062] 1. The inner reinforcement beam and the outer reinforcement beam are set at a 45° angle to each other;

[0063] 2. Replace the glass fiber plain cloth with basalt fiber unidirectional cloth;

[0064] 3. Use 50% aluminum honeycomb and 50% polyurethane honeycomb as the core material;

[0065] 4. Replace the epoxy resin curing system with the polyurethane resin curing system;

[0066] 5. The thickness of the skin layer covering the external reinforcing beam is 3 / 4 of the overall thickness of the skin layer, and the fiber content of the skin layer is 30%;

[0067] 6. The cross-section shapes of the inner reinforcement beam and the outer reinforcement beam are rectangle and "ㄩ" shape respectively.

[0068] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com