Aluminum alloy car body structure of rail car

A technology of aluminum alloy car body and rail vehicle, applied in the field of rail vehicle aluminum alloy car body structure, can solve the problems of peeling failure of the protective layer, lack of structural independence of the protective layer and noise reduction, etc., and achieve the effect of high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

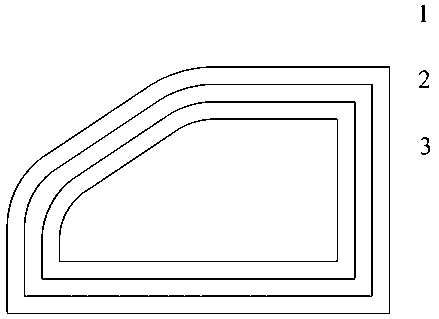

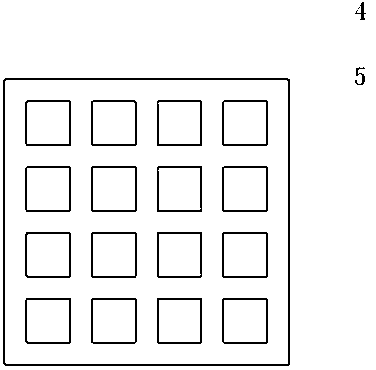

[0018] As illustrated in the figure: the aluminum alloy body structure of the new multifunctional rail vehicle of the present invention is mainly composed of an outer layer structure 1, a middle layer structure 2 and an inner layer structure 3. Wherein, the middle structure 2 is composed of a honeycomb structure and a noise reduction sponge. The outer structure 1 mainly uses materials with strong corrosion resistance, such as aluminum alloy with high corrosion resistance; the main structure of the middle structure 2 is a honeycomb structure 4 and the noise-reducing sponge 5 filled in the honeycomb holes; the inner structure 3 mainly Select high-strength materials, such as high-strength aluminum alloy, high-strength titanium alloy or high-strength composite materials.

[0019] The outer layer structure 1 and the inner layer structure 3 can adopt an integrated design, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com