Indexable cutting insert for rough machining

A cutting blade and indexing technology, which is applied in the field of indexable cutting blades, can solve the problems of high transverse bending stiffness, increased blade wear, and increased blade cutting resistance, so as to enhance impact resistance, improve cutting performance, and reduce cutting The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

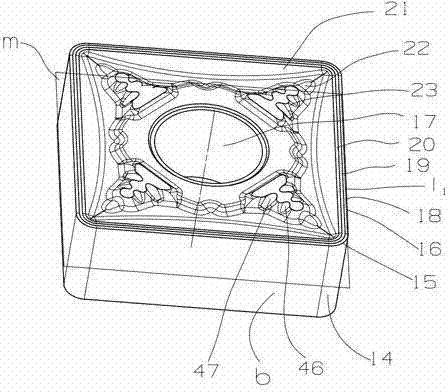

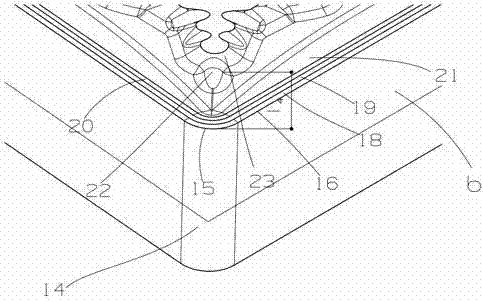

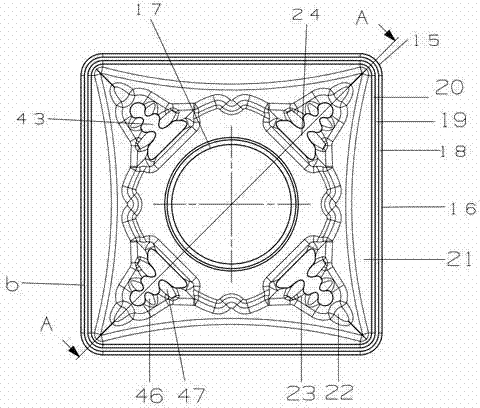

[0028] An indexable double-sided cutting insert, the insert body is a symmetrical square body up and down, such as Figure 1 to Figure 5 As shown, it includes two end surfaces and side surfaces, and four connection surfaces are arranged on the end surface, and the blade is positioned on the tool connection surface through the connection surfaces, specifically, fixed through the installation through hole 17 located at the geometric center of the blade body by a fixing screw . The two end faces of the blade body are arranged symmetrically with the middle section as the reference plane m, and the two adjacent side faces are connected by the arc surface 14; the eight cutting units are distributed at the angle between the two adjacent side faces of the upper and lower end faces, so that The cutting unit includes: the main cutting edge 15 formed by the intersection of the end surface and the arc surface 14, the intersection of the end surface and the side surface is a minor cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com