Vertical lifting mechanism for numerical-control lifting platform milling machine

A technology of vertical lifting mechanism and lifting table milling machine, which is applied in the direction of metal processing machinery parts, metal processing equipment, feeding devices, etc., and can solve the complex processing technology of lifting table, which affects the vertical lifting positioning accuracy and repeat positioning accuracy, assembly, adjustment, Difficulty in maintenance and other problems, to achieve the effect of improving positioning accuracy and repeat positioning accuracy, reducing processing complexity coefficient, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

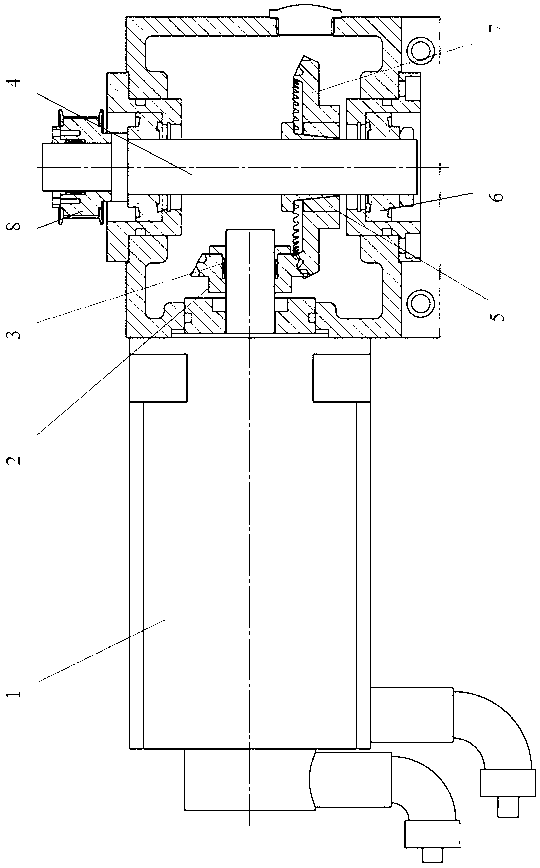

[0009] like figure 1 As shown, it is a vertical lifting mechanism of a CNC lifting table milling machine, including an output motor 1 and a transmission shaft 4. The output shaft of the output motor 1 is connected to the first bevel gear 2 through the first keyless bushing 3, and the transmission shaft 4 is connected to the output motor 1. The output shaft is vertically arranged, the transmission shaft 4 is connected to the second bevel gear 7 through the second keyless bushing 5, the second bevel gear 7 is meshed with the first bevel gear 2, and the two ends of the transmission shaft 4 are respectively provided with bearings 6 , one end of the transmission shaft 4 is also connected to the toothed pulley 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com