Preparation method and mold for microdefect high-utilization rate high-quality static ingot

A utilization rate and micro-defect technology, which is applied in the field of preparation of high-quality mold-cast steel ingots with high utilization rate of micro-defects, can solve the problems of wasting energy, material, manpower and material resources, restricting the development of high-quality forgings, and low utilization rate of steel ingots. Steel ingot utilization rate, reduction and shrinkage porosity and segregation problems, and the effect of improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

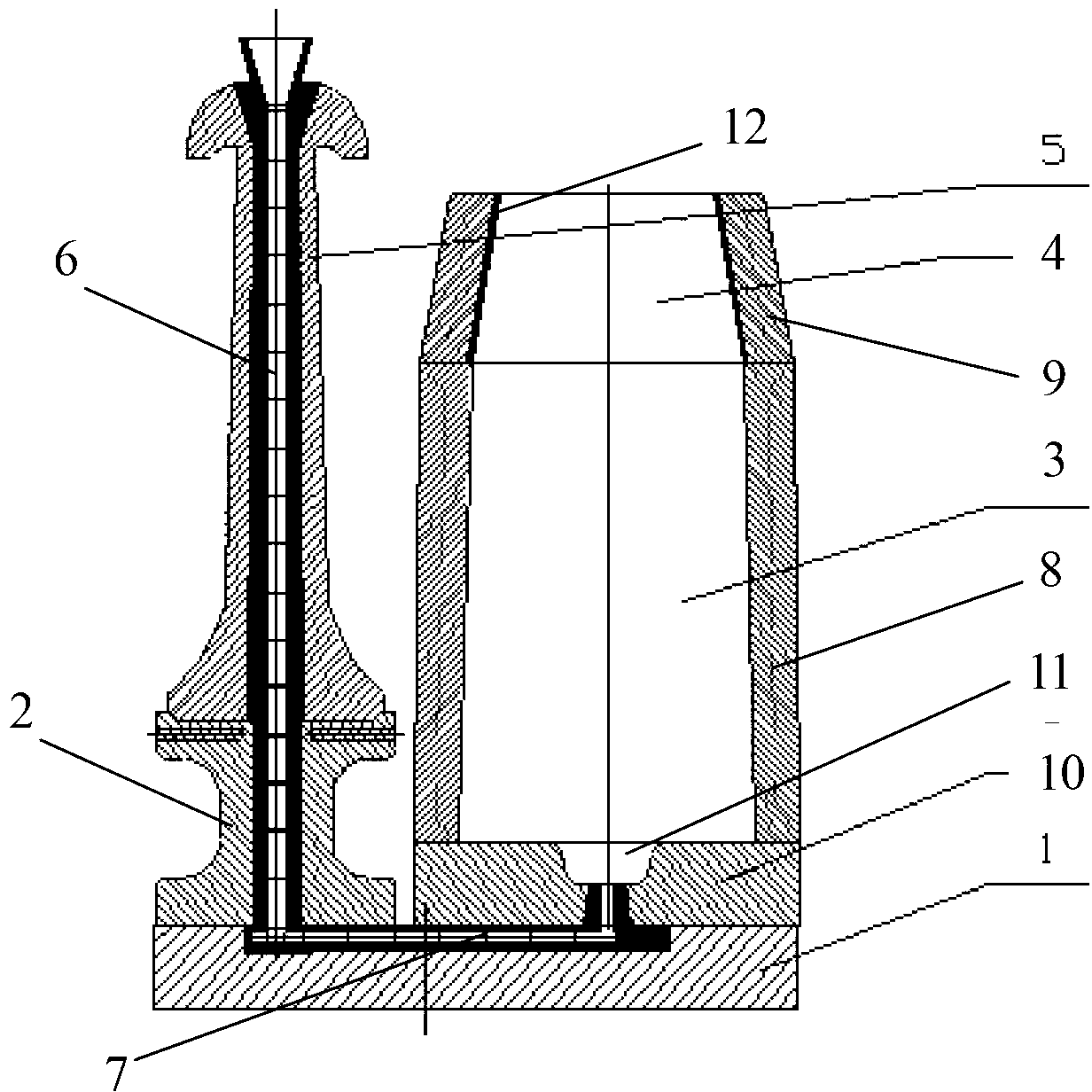

[0057] As shown in Figure 1(b), the cross-section of the trial-produced 2.5-ton ingot is a round steel ingot with a height-to-diameter ratio of 2.5. The pouring molten steel material is 42CrMo and the pouring temperature is 1540°C. After pouring, the nucleation operation is triggered by vibrating micro-zones on the riser. The vibration time is 8 minutes. After the riser vibrates, the plasma submerged arc heating gun is invaded into the molten metal to heat the ingot riser. The temperature of molten steel on the surface of the riser is 10-20°C higher than the liquidus line of this steel type. When the temperature of the steel ingot shell drops to 900°C, the mold will be demoulded. figure 2 As shown, the test results show that the core of the steel ingot is dense, and no shrinkage cavity porosity visible to the naked eye is found, and there is no type A segregation. In addition, no large inclusions were found in the negative segregation area at the tail of the ingot. Therefore,...

Embodiment 2

[0059] As shown in Figure 1(b), the cross-section of the trial-produced 5.5-ton ingot is a round steel ingot with a height-to-diameter ratio of 3. The pouring molten steel material is 42CrMo and the pouring temperature is 1540°C. After pouring, the nucleation operation is triggered by vibrating micro-zones on the riser. The vibration time is 10 minutes. The temperature of molten steel on the surface of the riser is 10-20°C higher than the liquidus line of this steel type. When the temperature of the steel ingot shell drops to 1000°C, the mold is demoulded. image 3As shown, the test results show that the core of the steel ingot is dense, no shrinkage cavity and loose defects visible to the naked eye are found, and there is a lighter type A segregation. In addition, no large inclusions were found in the negative segregation area at the tail of the ingot. Therefore, by using the vibration device in the riser of the steel ingot to perform micro-area triggered nucleation operatio...

Embodiment 3

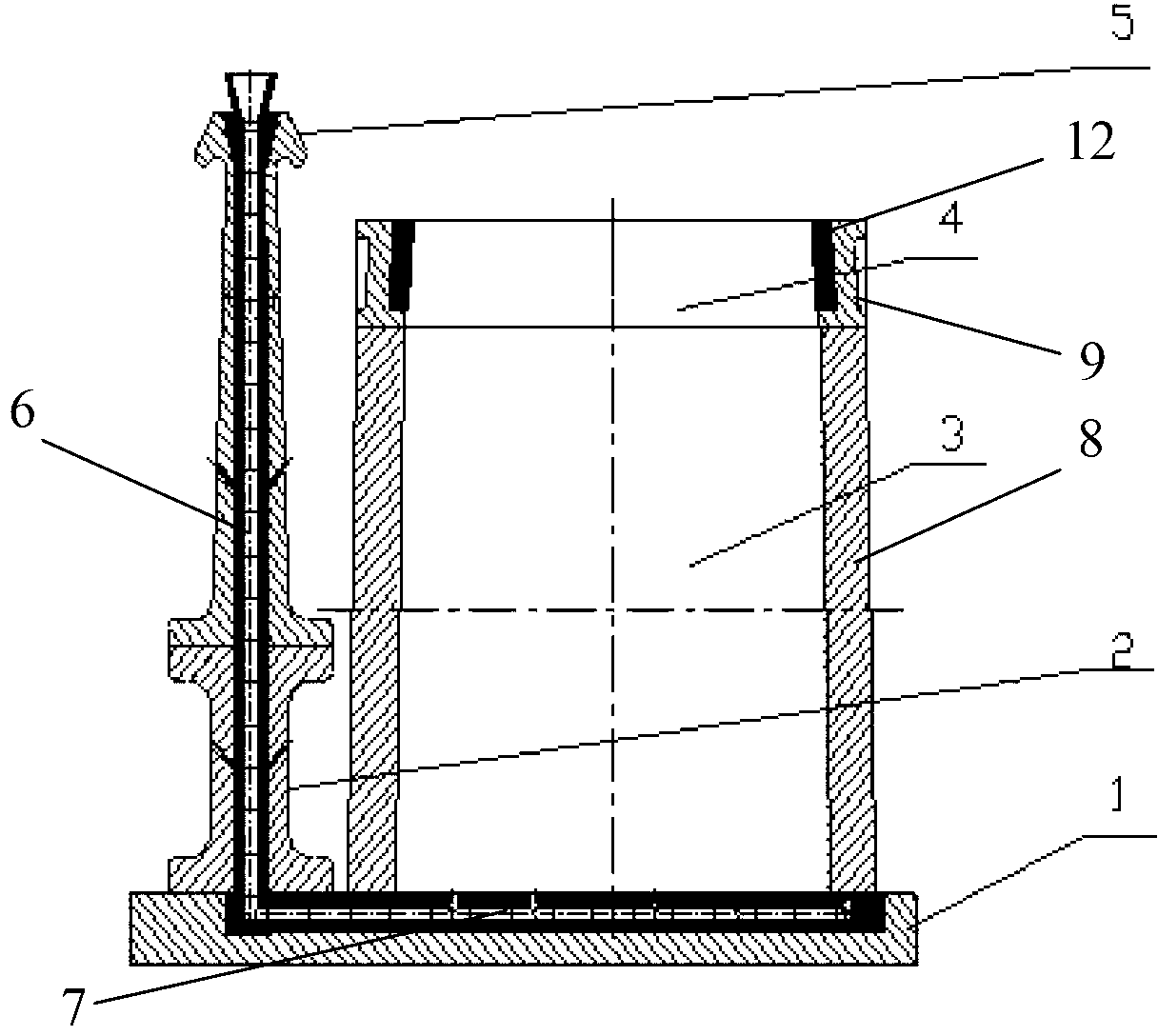

[0061] As shown in Figure 1(a), a 50-ton die-cast billet (square steel ingot) with a small top and a large bottom is developed, with a height-to-diameter ratio of about 4. The molten steel material is selected as Q345, and the pouring temperature is 1540°C. Using computer simulation technology to simulate the solidification process of steel ingots, such as Figure 4 As shown, for the common preparation process, the thermal junction area of the steel ingot is in the middle and lower part of the steel ingot, which is easy to cause serious shrinkage and porosity problems. Such serious shrinkage and porosity defects may make the forged product scrapped. In order to eliminate such defects, the steel ingot was demolded at a high temperature after solidification for 1 hour, followed by heat preservation treatment, and heat treatment on the riser. In order to prevent the riser from running out of steel, the riser was heated by a low-power submerged arc , and the heating area is mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com