Vanadium sodium phosphate composite material as well as preparation method and application thereof

A composite material, sodium vanadium phosphate technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems such as the electrochemical sodium storage performance is not given, and achieve good cycle performance, huge application prospects, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

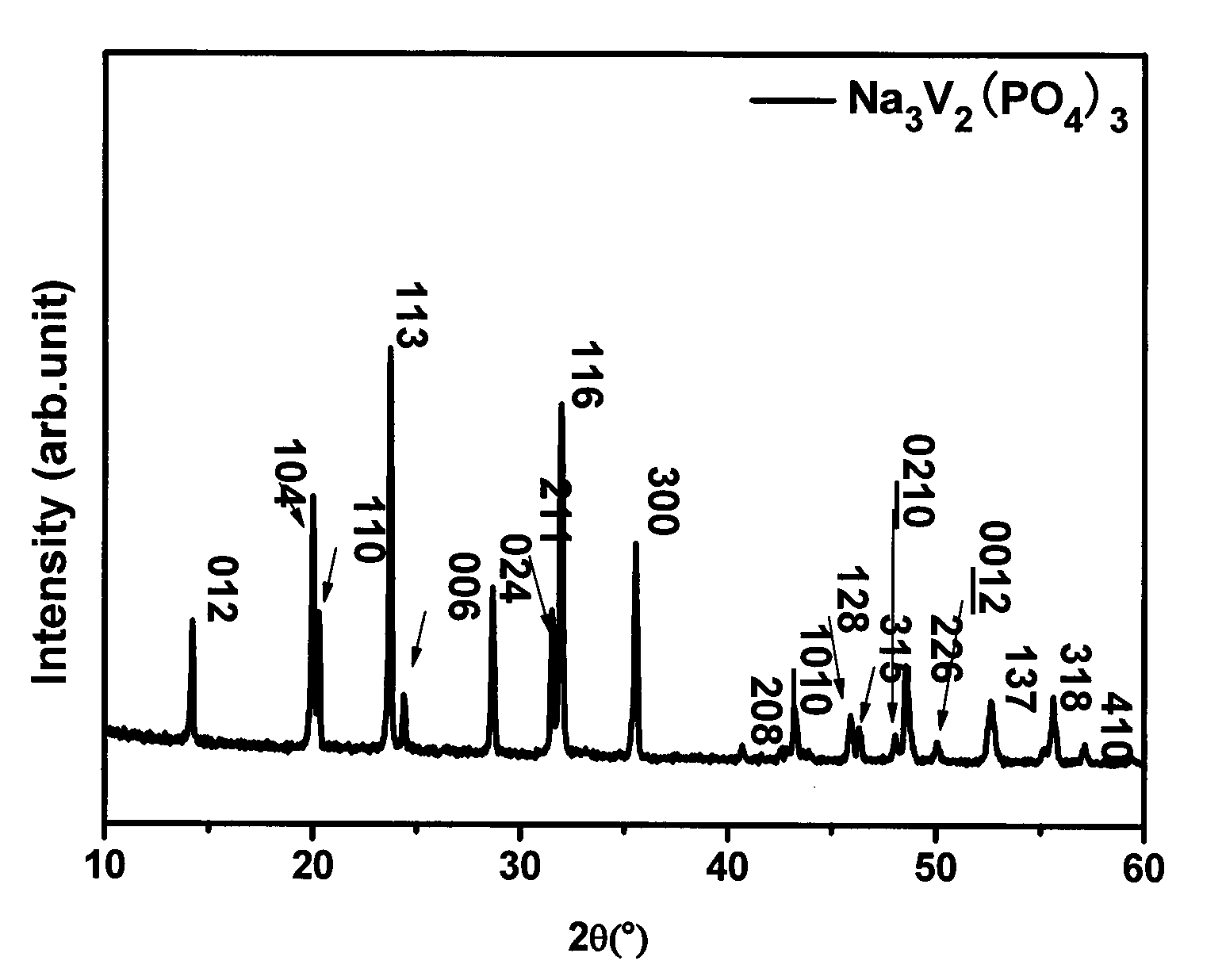

[0044] According to Na 3 V 2 (PO 4 ) 3 The ratio of each element in the formula is respectively high-purity V 2 o 3 powder and NaH 2 PO 4 2H 2 O powder was added into a ball milling jar, using ethanol as a medium, and ball milled for 5 hours; after drying and cooling, the Ar / H 2 (H 2 The content is 10%) in the mixed atmosphere, the temperature was raised to 800° C. at a heating rate of 5° C. / min, and the pure sample was obtained after keeping the temperature for 24 hours. figure 1 gives the pure phase Na 3 V 2 (PO 4 ) 3 The XRD diffraction pattern of the space group is

Embodiment 2

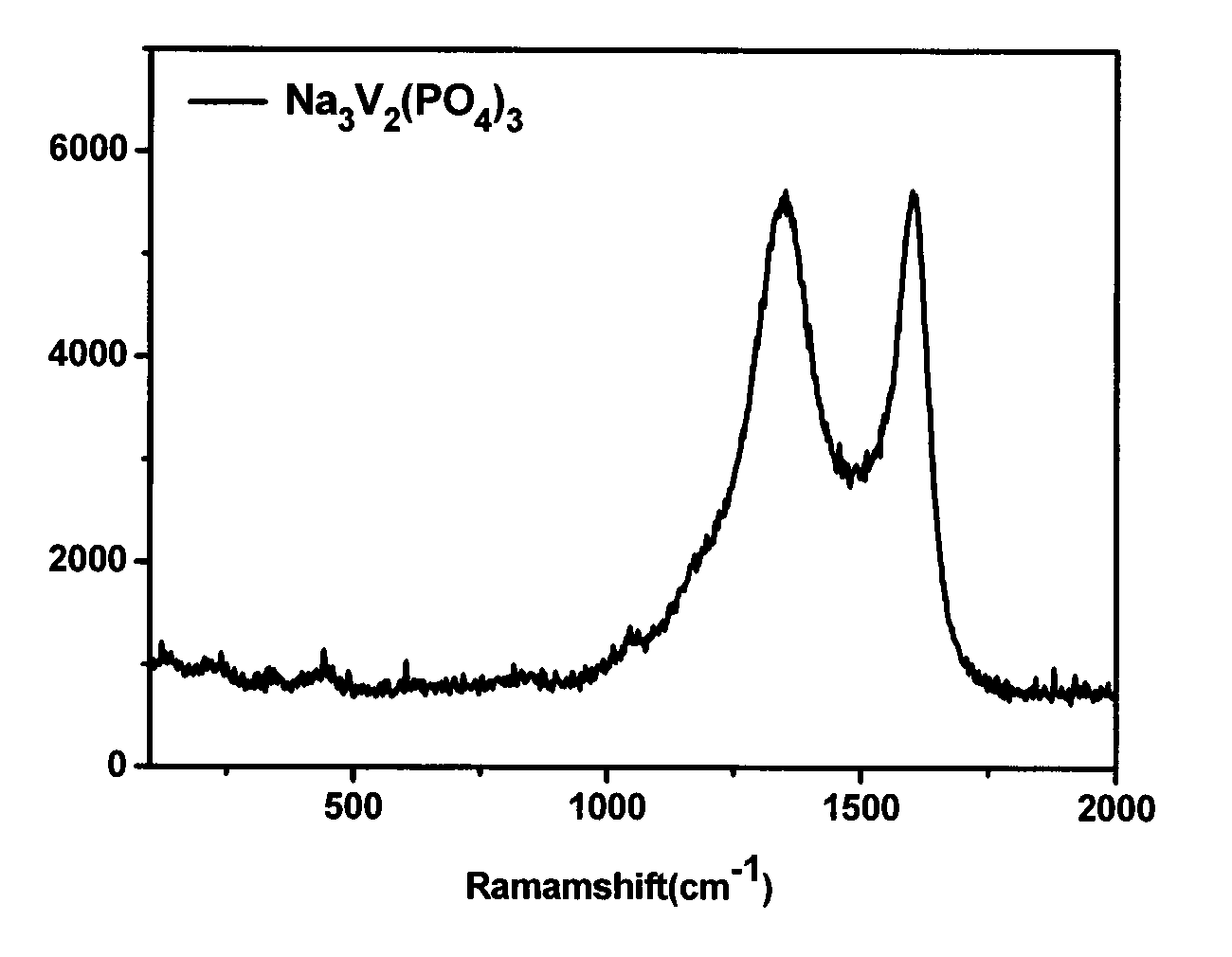

[0046] According to Na 3 V 2 (PO 4 ) 3 The ratio of each element in the formula is respectively high-purity V 2 o 3 powder and NaH 2 PO 4 2H 2 O powder was put into a ball mill jar, and a certain amount of sucrose was added, and ball milled for 5 hours with ethanol as the medium; after drying and cooling, the temperature was raised to 900°C in an Ar atmosphere at a rate of 5°C / min, and kept for 48 hours to obtain pure Sample. figure 2 gives the carbon-coated Na 3 V 2 (PO 4 ) 3 of the Raman spectrum. Raman spectroscopy showed that carbon was indeed present in the composite.

Embodiment 3

[0048] According to Na 3 V 2 (PO 4 ) 3 The ratio of each element in the formula is respectively high-purity V 2 o 3 powder and NaH 2 PO 4 2H 2 Add the O powder into a ball mill tank, and use ethanol as the medium, and ball mill for 5 hours; after drying and cooling, raise the temperature to 800°C at a rate of 5°C / min in an Ar atmosphere, and keep it for 12 hours to obtain a pure phase of Na 3 V 2 (PO 4 ) 3 .

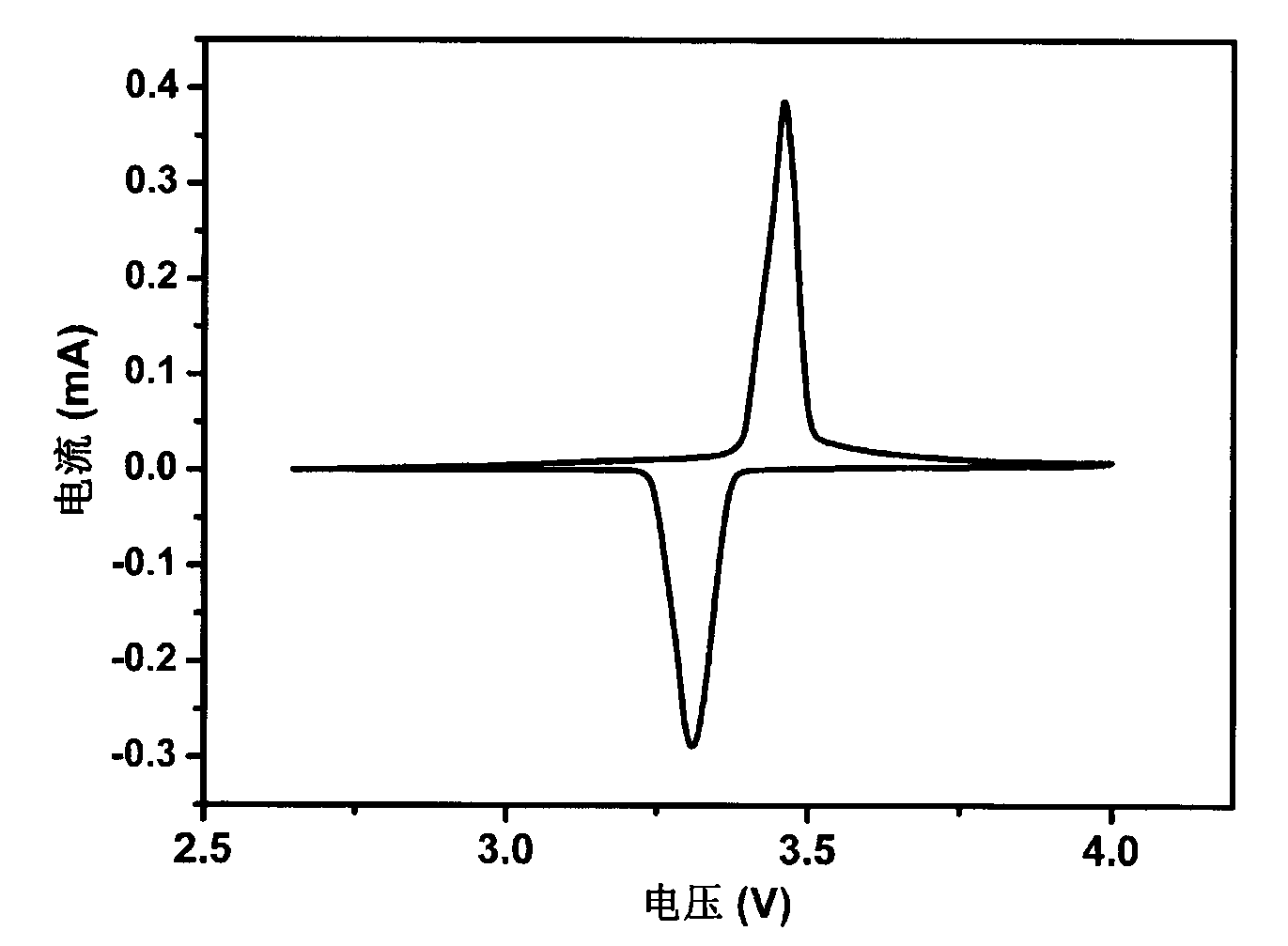

[0049] According to Na 3 V 2 (PO 4 ) 3 , acetylene black, and PVDF each accounted for 80%, 10%, and 10% were prepared into electrodes as an electrode of the half-cell, and the counter electrode was made of metal sodium, and 1mol / L of NaPF6 / ethylene carbonate (EC)-carbonic acid Diethyl ester (DEC) (the volume ratio of EC and DEC is 1:1) was used as the electrolyte, and the batteries were assembled in a glove box, and the cyclic voltammetry tests were performed on the batteries. The voltage range is 2.6-4V, the scan rate is 50uV / s, the test results are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com