Device and method for preparing water-containing coal sample and testing adsorption

An adsorption test, water coal technology, applied in the preparation of test samples, analysis materials, instruments, etc., can solve the problems that cannot reflect the influence of liquid water on gas adsorption, experimental results deviate from reality, and experimental troubles, etc., to achieve structure and method Simple, widely applicable, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

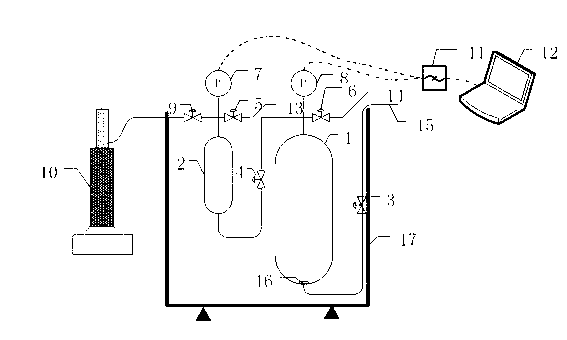

[0021] The water-containing coal sample preparation and adsorption measurement device of the present invention is mainly composed of a sample chamber 1, a reference chamber 2, a sample preparation drainage control valve 3, an adsorption control valve 4, a reference chamber pressure regulating valve 5, a sampling control valve 6, and a reference chamber pressure transmitter. 7, sample chamber pressure transmitter 8, intake control valve 9, gas injection pump 10, data acquisition card 11, acquisition terminal 12, reference chamber exhaust pipe 13, sampling pipe 14, sample preparation drain pipe 15, filter 16 , Constant temperature water bath 17 forms. The sample chamber 1 and the reference chamber 2 are arranged vertically, and their bottoms are conical or circular, forming a funnel shape; a filter 16 is provided at the connection between the bottom of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com