Injection-type high atomized oil gun

An ejector and oil gun technology, which is applied in the fields of ejector high atomization oil guns, oil gun mechanical devices and mechanical devices, can solve the problems of unsatisfactory oil particle atomization effect, poor flame stability and poor uniformity. , to achieve the effect of good oil flame stability, good uniformity and improved burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

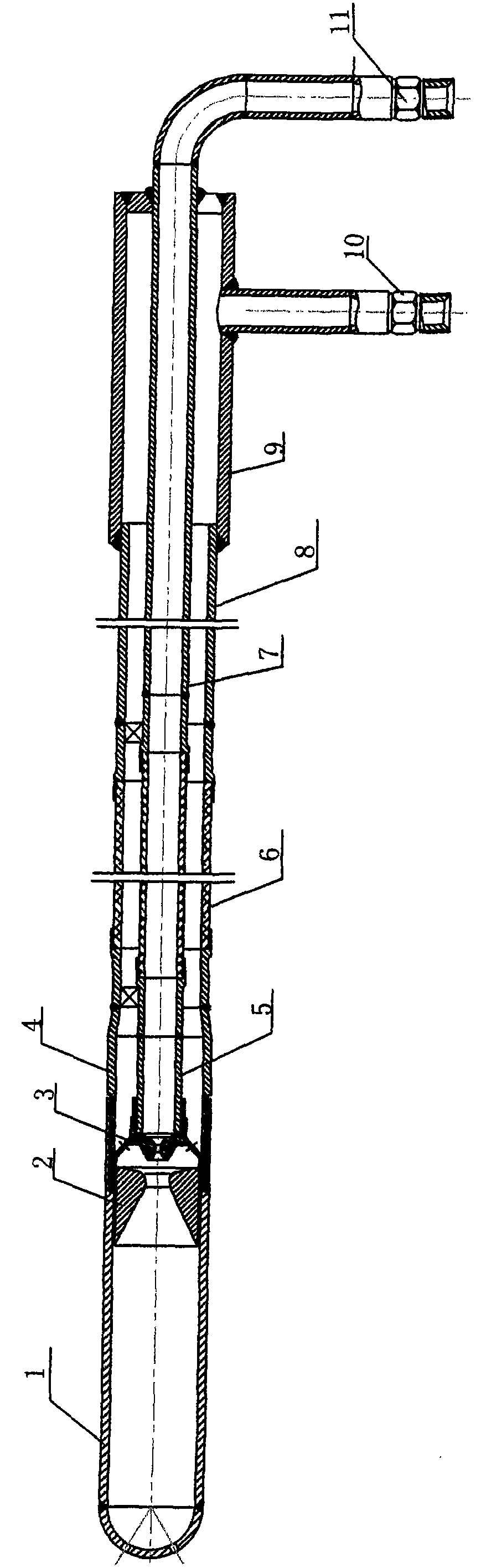

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0022] An injection-type high-atomization oil gun, consisting of a mixing chamber 1, a zoom body 2, a jet nozzle 3, an outer short 4, an inner short 5, a metal hose 6, an inner tube 7 of the oil gun, and an outer tube of the oil gun 8. The fixed end sleeve of the oil gun is composed of 9, air interface 10, and oil interface 11;

[0023] The ejection type high atomization oil gun, its oil interface 11 is fixedly connected with the rear end of the inner tube 7 of the oil gun, the inner tube 7 of the oil gun and the hole on the disc-shaped plug at the rear end of the fixed end sleeve 9 of the oil gun are all fixedly connected , the front end of the inner pipe 7 of the oil gun is fixedly connected with the rear end of the inner short-connect 5 through a section of inner metal hose, and the front end of the inner short-connect 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com