Compressed air driven metering device of tail gas purification after-treatment system of internal combustion engine

A technology for exhaust gas purification and compressed air, which is applied in the direction of exhaust devices, noise reduction devices, machines/engines, etc., which can solve problems such as short service life, poor reliability, and anti-crystallization blockage, and achieve saving installation space, simple structure, and avoiding waterproofing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

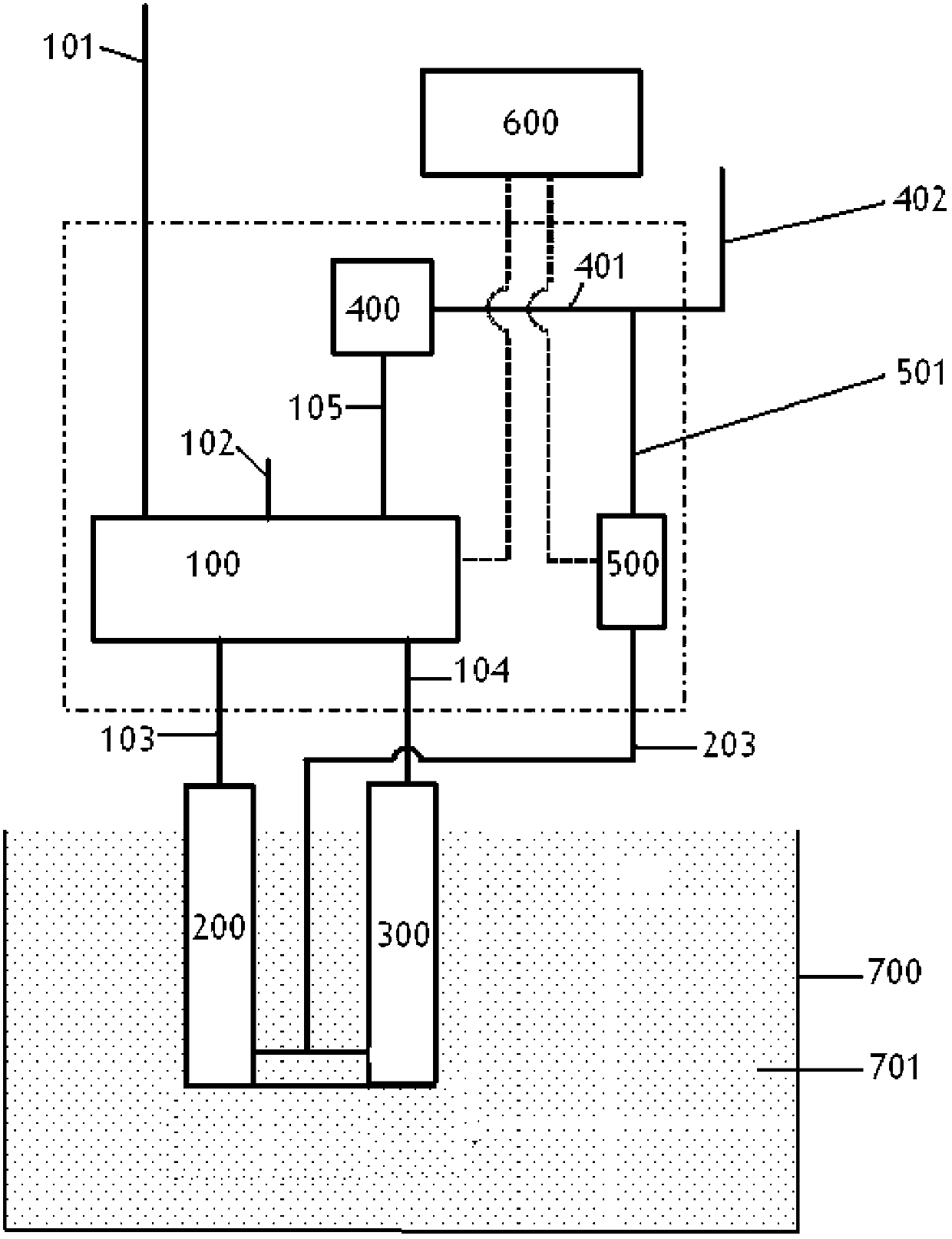

[0032] see figure 1 As shown, a metering device driven by compressed air for an internal combustion engine exhaust gas purification post-treatment system includes an air control valve 100, a first liquid chamber 200, a second liquid chamber 300, a first pressure reducing device 400, a metering valve 500 and a controller 600;

[0033] The air control valve 100 is externally connected to compressed air through the first pipeline 101, connected to the atmosphere through the second pipeline 102 (or indirectly connected to the atmosphere through other devices, such as a reactant storage tank), and connected to the first liquid chamber 200 through the third pipeline 103. Connected and communicated, connected and communicated with the second liquid chamber 300 through the fourth pipeline 104, connected and communicated with the first decompression device 400 through the fifth pipeline 105;

[0034] The first liquid chamber 200 is provided with a first liquid inlet check valve 201 an...

Embodiment 2

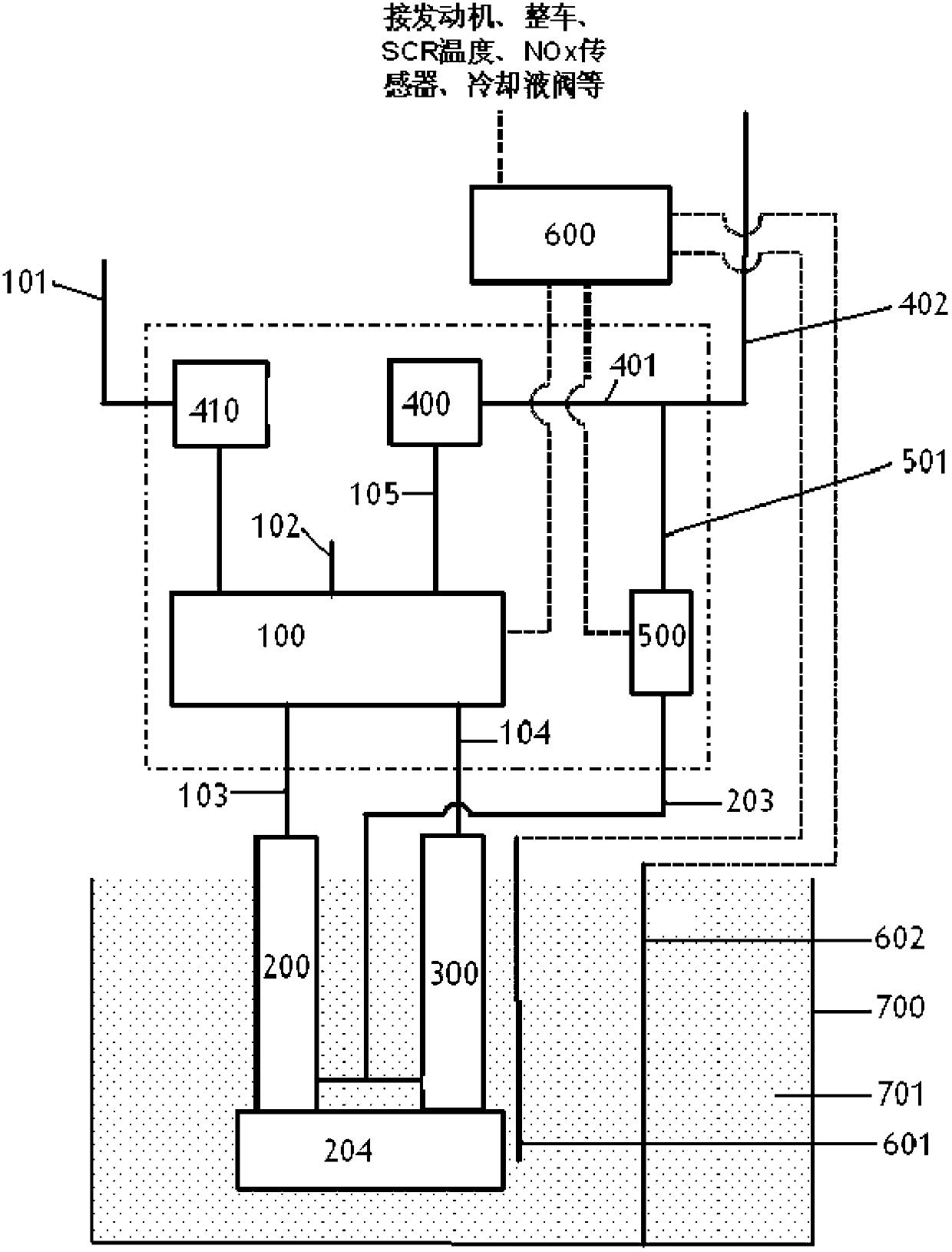

[0039] see image 3 As shown, repeat embodiment 1, the difference is that the metering device also includes the following technical features:

[0040] The first pipeline 101 is provided with a second decompression device 410; since the pressure produced by the current vehicle-mounted air brake system is mostly between 8 and 12 bars, it is inconvenient to use it directly. In order to facilitate the use of the compressed air produced by the vehicle-mounted air brake system , add a second decompression device 410.

Embodiment 3

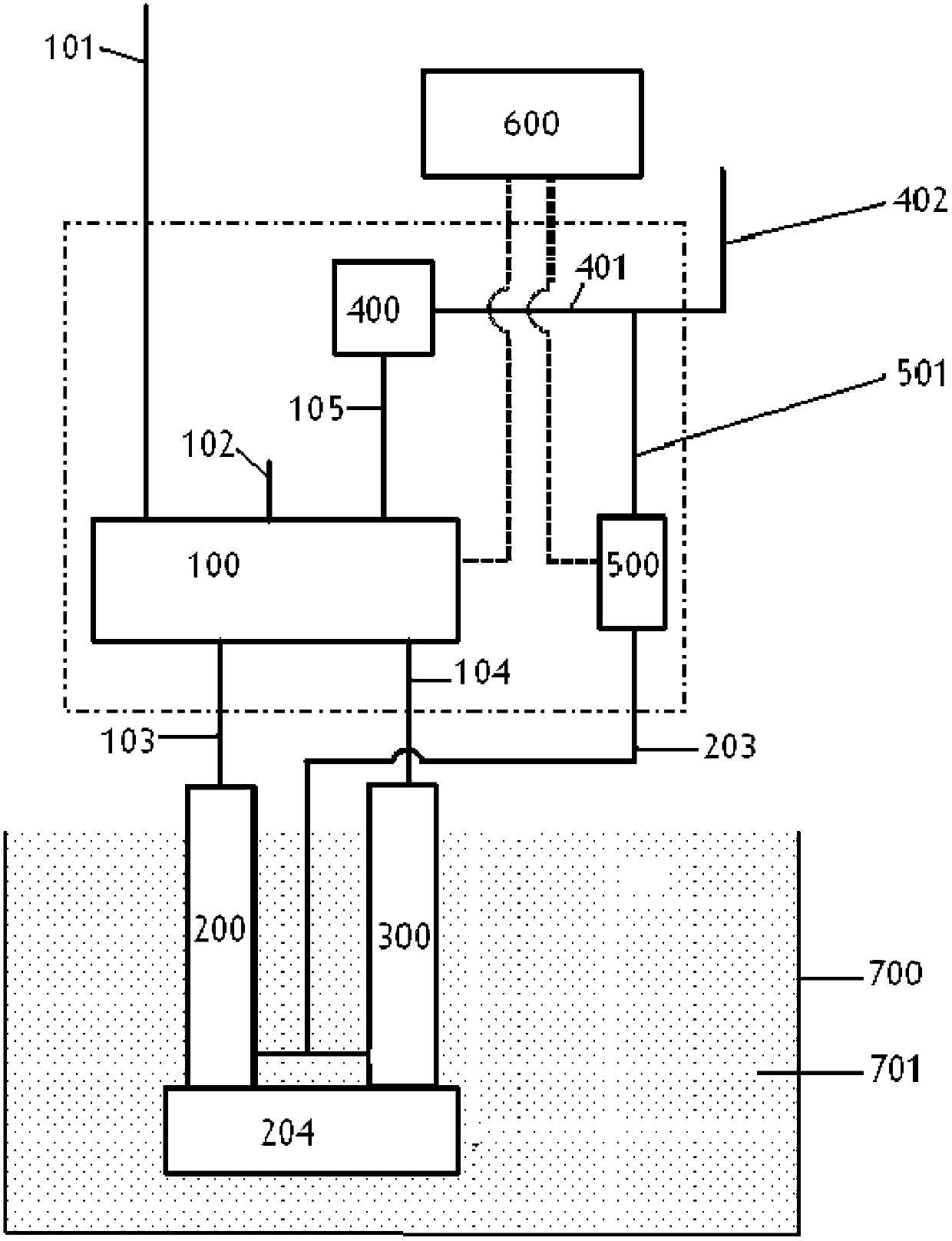

[0042] see figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown, repeat embodiment 2, its difference is that described metering device also comprises following technical feature:

[0043] The inlet of the first liquid inlet check valve 201 and the inlet of the second liquid inlet check valve 301 are provided with a shared filter 204; so that the reactants entering the check valves 201, 301 will not contain particulate impurities. And block the pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com