L-d-glutamic oxidase with substrate specificity and alpha-oxoglutarate produced by catalysis of same

A technology of glutamic acid oxidase and sodium glutamate, which is applied in the direction of enzymes, microorganisms, and methods based on microorganisms, can solve problems such as environmental pollution and raw material sources, and achieve reduced operation difficulty, low production costs, and simple production processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

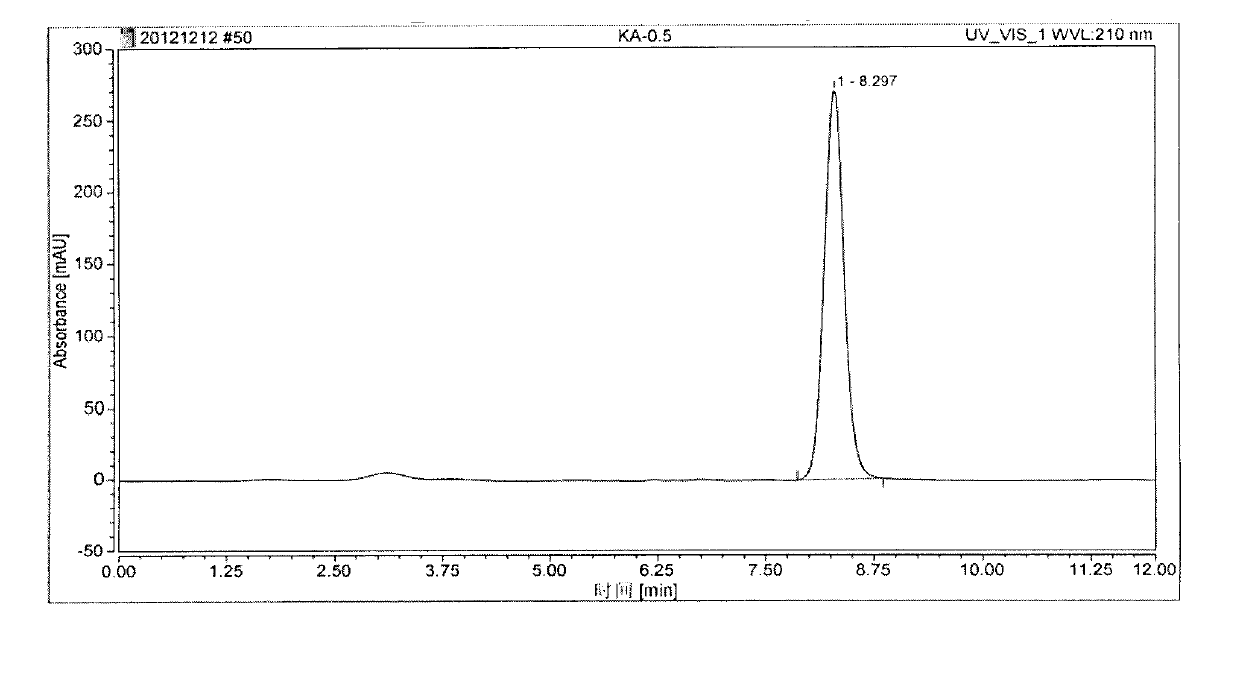

[0025] 1. L-glutamate oxidase substrate specificity experiment:

[0026] According to the Trinder reaction, the L-type amino acid solution with a concentration of 11 mg / mL was prepared with pH 7.0 phosphate buffer solution for color reaction measurement. After an accurate reaction at 30°C for 30 minutes, it was boiled at 100°C for 5 minutes and measured at 550 nm.

[0027]

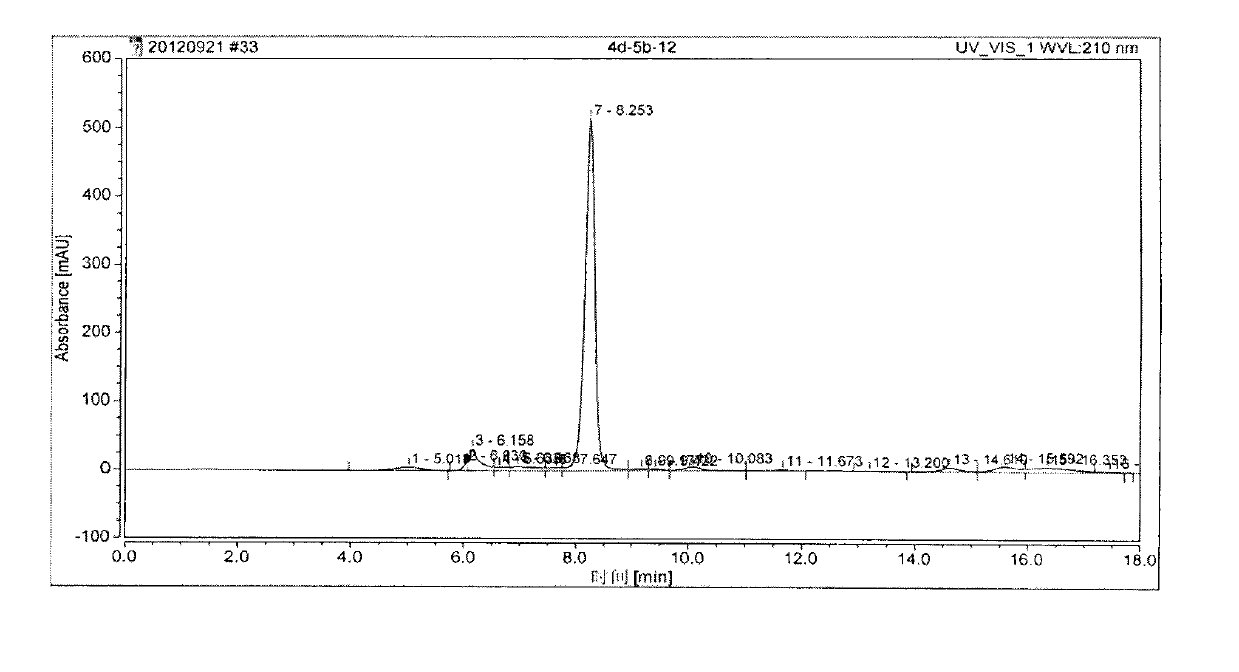

[0028] 2. The effect of different pH on the catalytic transformation of L-glutamic acid oxidase:

[0029] Prepare the fermentation broth containing L-glutamic acid oxidase in different pH range gradients from 5.5 to 10.5, add 20g / L sodium L-glutamate solution, transform for 12 hours, and measure the content of α-ketoglutaric acid in the fermentation broth . As a preferred version of the present invention, 8.5 is selected as the conversion pH, at which time the conversion rate is the highest and is closest to the pH of the fermentation broth.

[0030]

[0031]

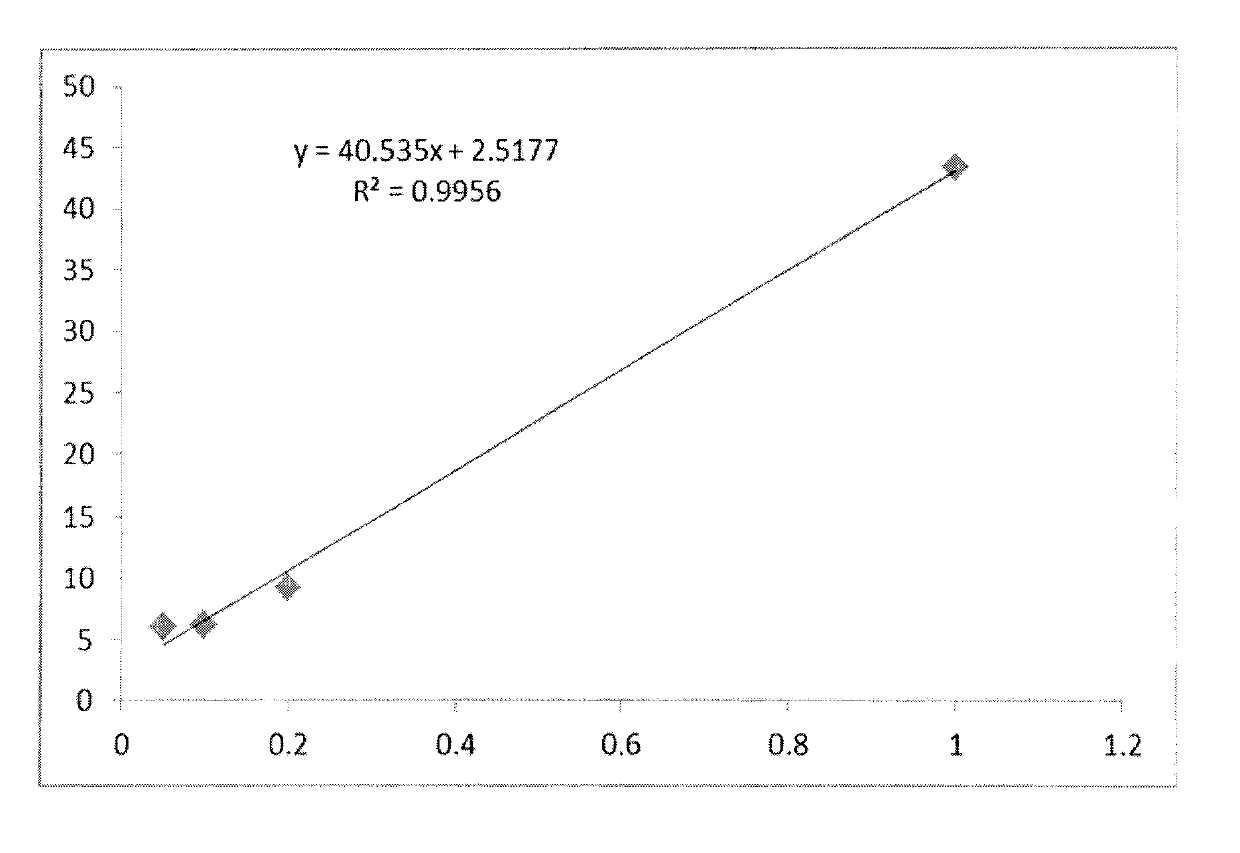

[0032] 3. Put 40mL of enzyme-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com