High-temperature-resistant non-silicate cement paste system for cementing thermal production well of thickened oil

A high-temperature-resistant cement and heavy oil thermal recovery technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems affecting the production efficiency of heavy oil thermal recovery wells, casing damage, gas and bubbles at the well site, etc. , to achieve the effect of adjustable density and thickening time, broad application prospects and convenient on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Formula: 100 parts of high temperature resistant cement, 1 part of polyvinyl alcohol, 4 parts of melamine formaldehyde resin, 0.5 part of limestone, 15 parts of 300 mesh slag and 60 parts of water.

[0030] High temperature resistant cement is made by mixing component A and component B at a weight ratio of 1:1. The chemical composition of component A and the clinker mineral composition of component B are as follows:

[0031]

[0032]

Embodiment 2

[0034] Formula: 100 parts of high temperature resistant cement, 2 parts of hydrolyzed polyacrylonitrile, 3 parts of calcium lignosulfonate, 2 parts of boric acid, 50 parts of 800 mesh fly ash and 80 parts of water.

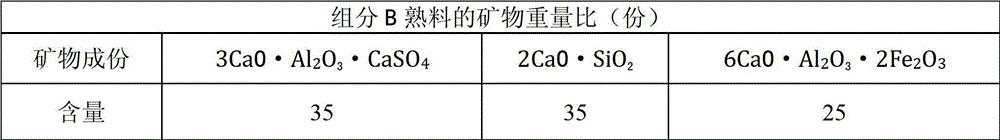

[0035] High temperature resistant cement is made by mixing component A and component B at a weight ratio of 1:1. The chemical composition of component A and the clinker mineral composition of component B are as follows:

[0036]

[0037]

Embodiment 3

[0039] Formula: 100 parts of high temperature resistant cement, 4 parts of carboxymethyl cellulose, 1 part of sodium hexametaphosphate, 3 parts of sodium borate, 80 parts of 1500 mesh slag and 120 parts of water.

[0040] High temperature resistant cement is made by mixing component A and component B at a weight ratio of 1:1. The chemical composition of component A and the clinker mineral composition of component B are as follows:

[0041]

[0042]

[0043] 2. Performance test of high temperature resistant non-portland cement slurry system for heavy oil thermal recovery well cementing

[0044] Example 1, Example 2, and Example 3 were used to prepare cement slurry according to the cement slurry API experimental standard, and the density, fluidity, fluid loss, compressive strength and thickening time of the cement slurry were measured. The engineering performance results of the high temperature resistant cement slurry system for thermal recovery well cementing are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com