Reinforcing addition type liquid silicone rubber bonding accelerant and preparation method and application thereof

An adhesion promoter, liquid silicone rubber technology, applied in the direction of adhesives, adhesive additives, chemical instruments and methods, etc., can solve the problems of platinum catalyst poisoning, complicated preparation process, easy to generate gel, etc., and achieve the ability to resist external force Enhancement, simple preparation process, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 12.82g of pentaerythritol triallyl ether (APE) and 11.82g of 3-(2,3-epoxypropoxy)propyltrimethoxysilane (KH-560) into a three-necked flask with a thermometer and a condensing reflux tube, Stir evenly at room temperature, then add 0.25 g of tetrabutyl titanate dropwise under stirring conditions, raise the temperature to 80° C. for 2 h, and finally continue the reaction for 2 h under a vacuum of 0.5 kPa to obtain the product adhesion promoter 1.

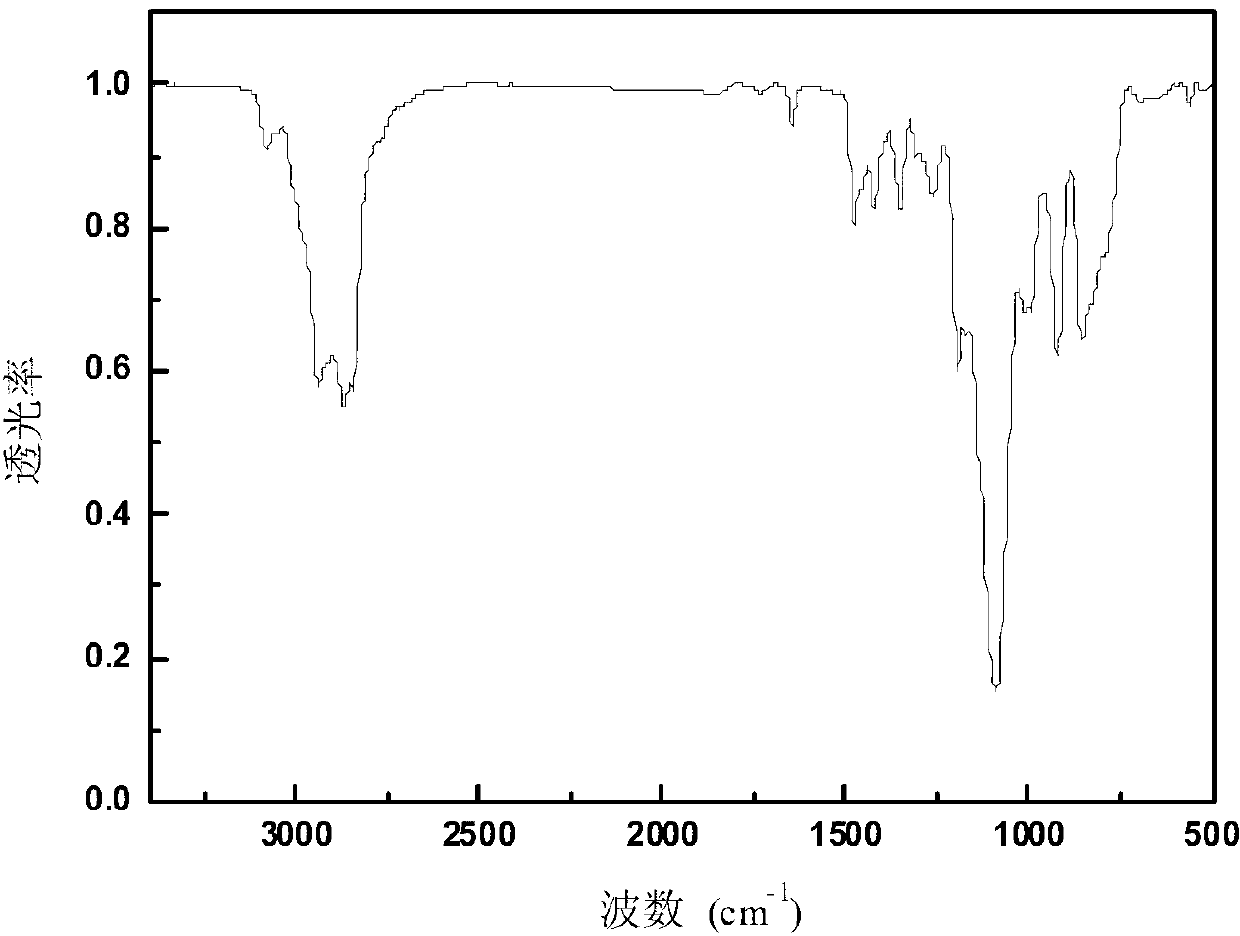

[0033] To the infrared spectrum of adhesion promoter 1 ( figure 1 ) for analysis at 2844cm -1 The absorption peak of methoxy group appears at 1646cm -1 The absorption peak of the double bond appears at 922cm -1 The C-H absorption peak in the alkenyl group and the absorption peak of the epoxy group appear at the place.

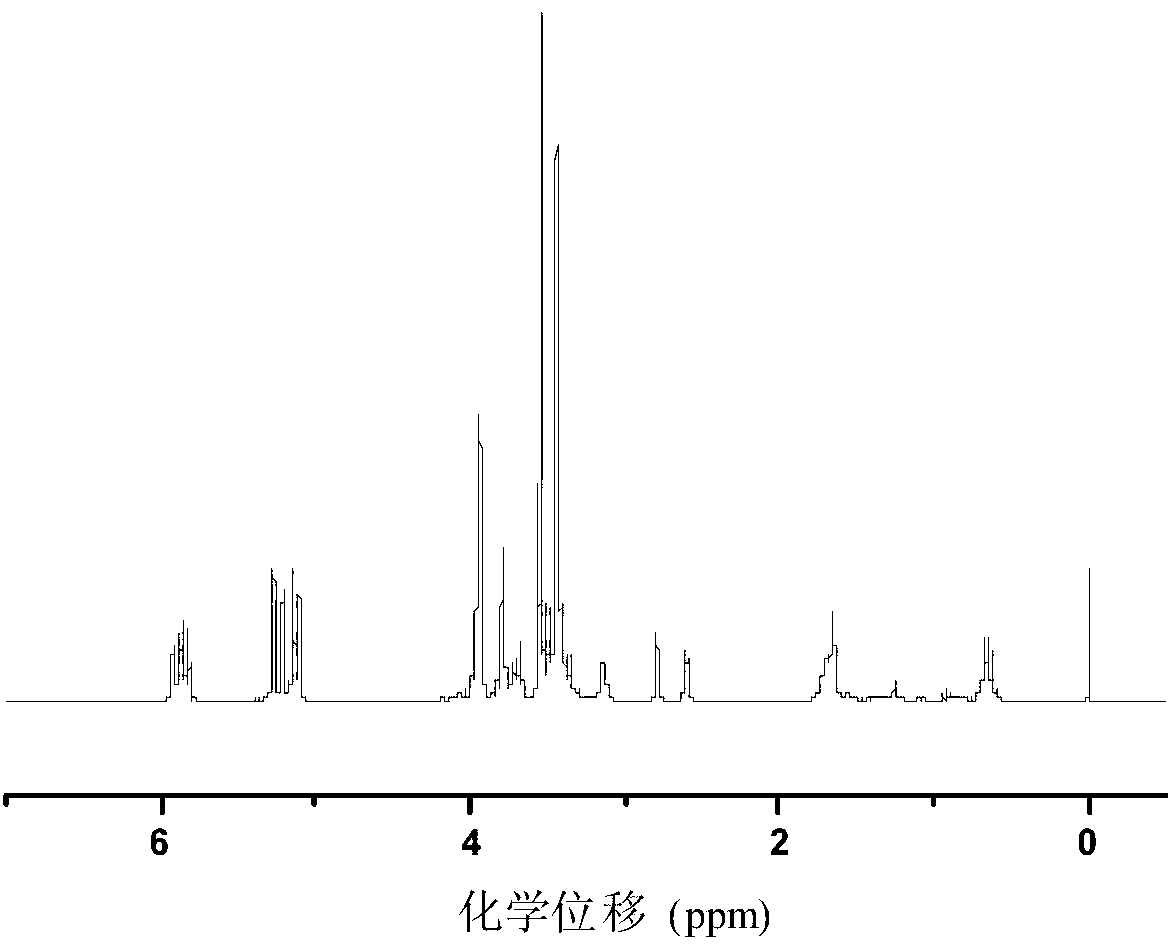

[0034] The H NMR spectrum of adhesion promoter 1 ( figure 2 ) analysis, the peak at the chemical shift 5-6ppm is produced by the hydrogen proton in the double bond, the peak at the chemical shift 3.54ppm...

Embodiment 2

[0039] Add 12.82g of APE and 18.02g of 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane (KH-567) into a three-necked flask with a thermometer and a condensing reflux tube, and stir evenly at room temperature , then added dropwise 0.15 g of tetrabutyl titanate under stirring conditions, raised the temperature to 130° C. for 1 h, and finally continued the reaction for 1 h under a vacuum of 0.01 kPa to obtain the product adhesion promoter 2.

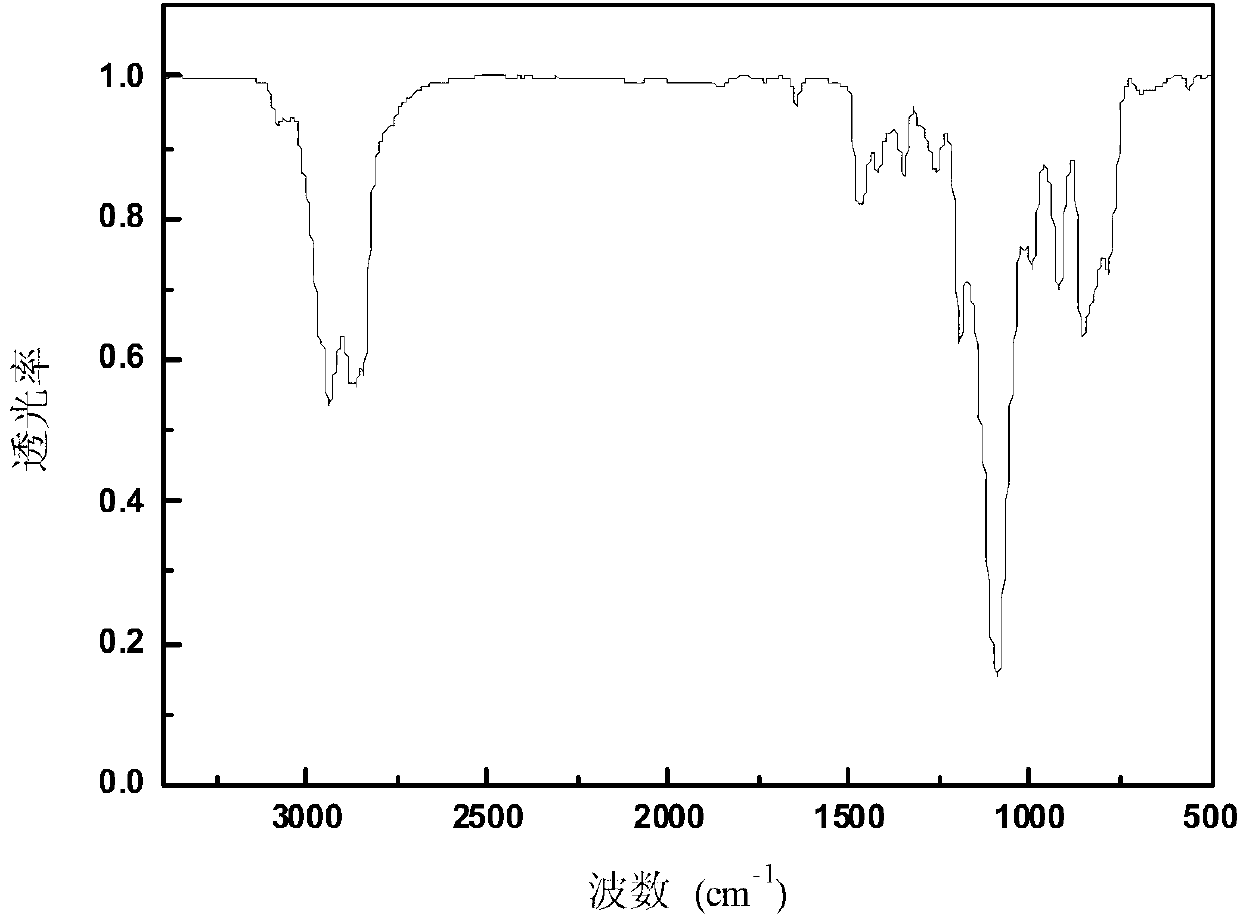

[0040] Infrared spectrum and hydrogen nuclear magnetic spectrum analysis of adhesion promoter 2 shows that its structure is:

[0041]

[0042] 40 parts by mass of vinyl silicone oil with a viscosity of 300mPa·s, 60 parts by mass of vinyl silicone oil with a viscosity of 1000mPa·s, 120 parts by mass of alumina with an average particle size of 5μm, 2.5 parts by mass of adhesion promoter 2, and 6.33 parts by mass of One part of hydrogen-containing silicone oil with a hydrogen content of 0.5% and 0.004 parts by mass of 1-ethynyl-1-cyclohexanol ar...

Embodiment 3

[0044] The difference between this example and Example 1 is that KH-560 is changed to 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane (KH-566), and its dosage is 12.32g, Adhesion Promoter 3 was prepared.

[0045] The infrared spectrum and hydrogen nuclear magnetic spectrum analysis of the adhesion promoter 3 shows that its structure is:

[0046]

[0047] Change adhesion promoter 1 to adhesion promoter 3, and its consumption is 1.5 mass parts, and the consumption of corresponding hydrogen-containing silicone oil is reduced to 6.3 mass parts, the divinyltetramethyldisiloxane complex of chloroplatinic acid The amount of compound was changed to 1.52 parts by mass. The performance of cured sample is as shown in table 1, and its shear strength is 0.96MPa, and tensile strength is 3.01MPa, has improved respectively 182% and 35% with respect to the shear strength of comparative example 1 and tensile strength, shows that KH Adhesion promoter 3 prepared by -566 instead of KH-560 can si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com