Waterborne epoxy conductive paint and preparation method thereof

A technology of water-based epoxy and conductive paint, which is applied in the field of conductive paint and can solve the problems that the conductive performance of paint needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] A water-based epoxy conductive paint, the conductive paint is mainly composed of component A and component B:

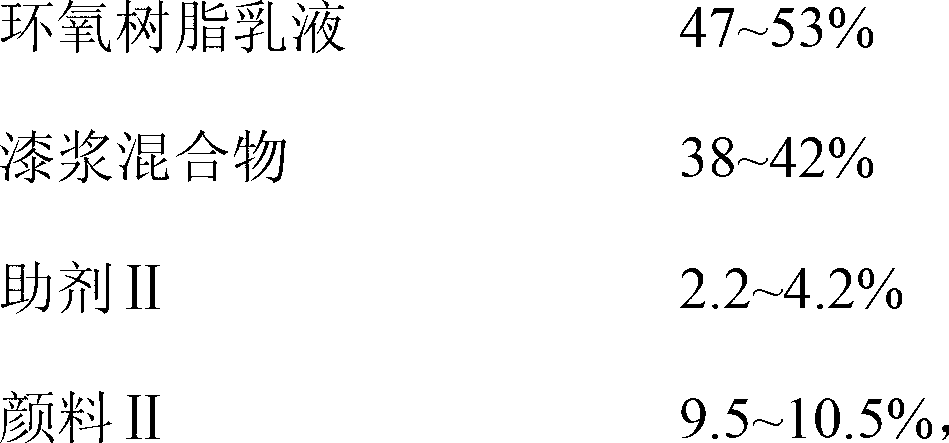

[0086] The first component comprises the following components by weight percentage:

[0087]

[0088] The sum of the above components is 100%;

[0089] The auxiliary agent II is a mixture of hydroxyethyl cellulose, polydimethylsiloxane and polymethylalkylsiloxane.

[0090] The pigment II is a floating aluminum silver paste.

[0091] Wherein, the mill base mixture comprises the following components by weight percentage:

[0092]

[0093]

[0094] The pigment I is a mixture of nano titanium dioxide, ultrafine conductive mica powder, fumed silicon dioxide and gray mica iron oxide.

[0095] The auxiliary agent I is a mixture of fatty acid ethylene oxide adduct, DA-50 multifunctional auxiliary agent and polydimethylsiloxane.

[0096] The second component is a curing agent and an emulsifying agent, and the curing agent is a polyamide curing agent with a...

Embodiment 2

[0102] A water-based epoxy conductive paint, the conductive paint is mainly composed of component A and component B:

[0103] The first component comprises the following components by weight percentage:

[0104]

[0105] The sum of the above components is 100%;

[0106] The auxiliary agent II is a mixture of methyl hydroxypropyl cellulose, polymethyl alkyl siloxane and mineral oil.

[0107] The pigment II is a floating aluminum silver paste.

[0108] Wherein, the mill base mixture comprises the following components by weight percentage:

[0109]

[0110] The pigment I is a mixture of nano titanium dioxide, ultrafine conductive mica powder, fumed silicon dioxide and gray mica iron oxide.

[0111] The auxiliary agent I is a mixture of silicate, DA-50 multifunctional auxiliary agent and polydimethylsiloxane.

[0112] The second component is a curing agent and an emulsifying agent, and the curing agent is a polyamide curing agent with a solid content of 70%, and the weight...

Embodiment 3

[0118] A water-based epoxy conductive paint, the conductive paint is mainly composed of component A and component B:

[0119] The first component comprises the following components by weight percentage:

[0120]

[0121]

[0122] The sum of the above components is 100%;

[0123] The auxiliary agent II is a mixture of methylhydroxypropyl cellulose, polymethylalkylsiloxane and polydimethylsiloxane.

[0124] The pigment II is a floating aluminum silver paste.

[0125] Wherein, the mill base mixture comprises the following components by weight percentage:

[0126]

[0127] The pigment I is a mixture of nano titanium dioxide, ultrafine conductive mica powder, fumed silicon dioxide and gray mica iron oxide.

[0128] The auxiliary agent I is a mixture of silicate, DA-50 multifunctional auxiliary agent and polydimethylsiloxane.

[0129] The second component is a curing agent and an emulsifying agent, and the curing agent is a polyamide curing agent with a solid content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com