Zinc powder-free shop primer and preparation method thereof

A shop primer and zinc powder technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of high price, high rust removal requirements, and secondary flash rust, so as to reduce labor costs and increase interaction Solubility, the effect of strong solvency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A shop primer comprising:

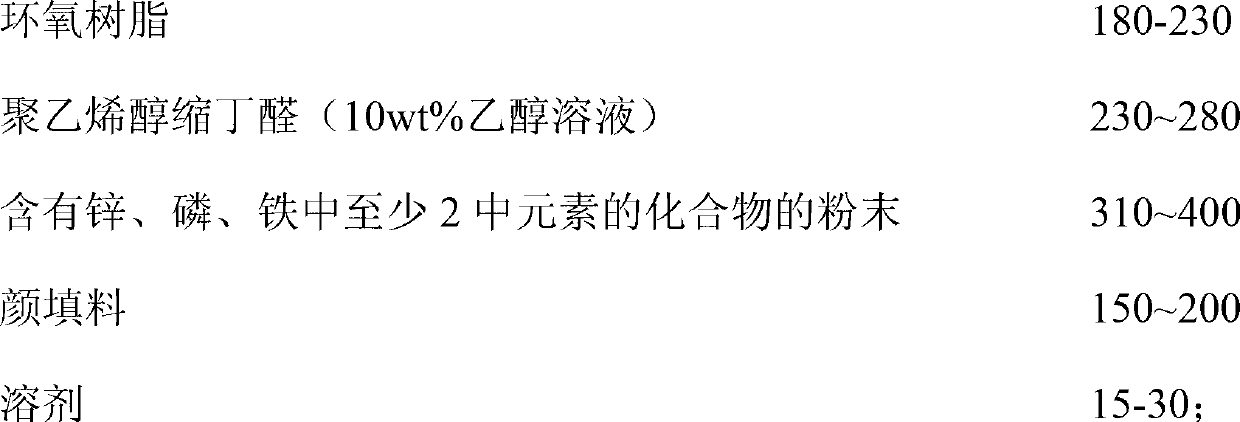

[0076] (a) Group A includes by weight parts:

[0077]

[0078] (b) Component B includes by parts by weight:

[0079] Curing agent 40

[0080] Solvent 55;

[0081] The preparation method of the shop primer includes: dispersing→stirring→varnishing→inspection→filtering→packaging. The construction method of the shop primer is: fully mix and stir the components A and B before construction, and then paint, It is necessary to ensure that the mixed shop primer is used up within 24 hours.

Embodiment 2

[0083] A shop primer comprising:

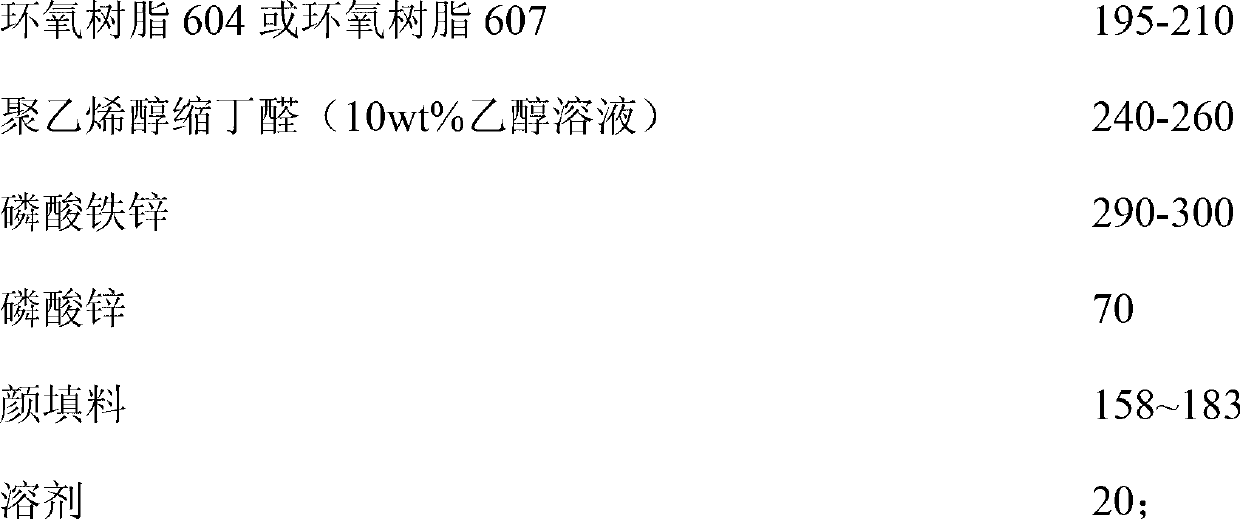

[0084] (a) Group A includes by weight parts:

[0085]

[0086]

[0087] (b) Component B includes by parts by weight:

[0088] Curing agent 30

[0089] Solvent 75;

[0090] The preparation method of the shop primer includes: dispersing→stirring→varnishing→inspection→filtering→packaging. The construction method of the shop primer is: fully mix and stir the components A and B before construction, and then paint, It is necessary to ensure that the mixed shop primer is used up within 24 hours.

Embodiment 3

[0092] A shop primer comprising:

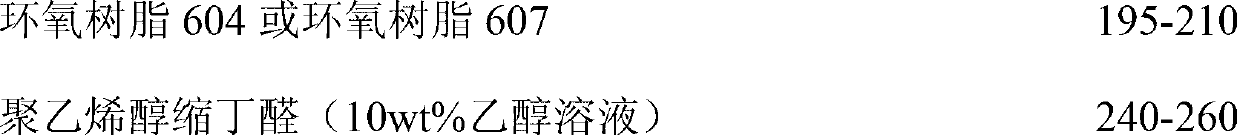

[0093] (a) Group A includes by weight parts:

[0094]

[0095] (b) Component B includes by parts by weight:

[0096] Curing agent 35

[0097] Solvent 65.

[0098] The preparation method of the shop primer includes: dispersing→stirring→varnishing→inspection→filtering→packaging. The construction method of the shop primer is: fully mix and stir the components A and B before construction, and then paint, It is necessary to ensure that the mixed shop primer is used up within 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com