Solvent volatilization self-assembly method used for preparing multistage-channel SAPO-34 and SAPO-18 molecular sieves

A molecular sieve and channel technology, which is applied in the field of preparation of multi-stage porous silicon-phosphorus-aluminum molecular sieves, can solve the problems of high cost, restricting the industrialization of multi-stage porous molecular sieves, and expensive templates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

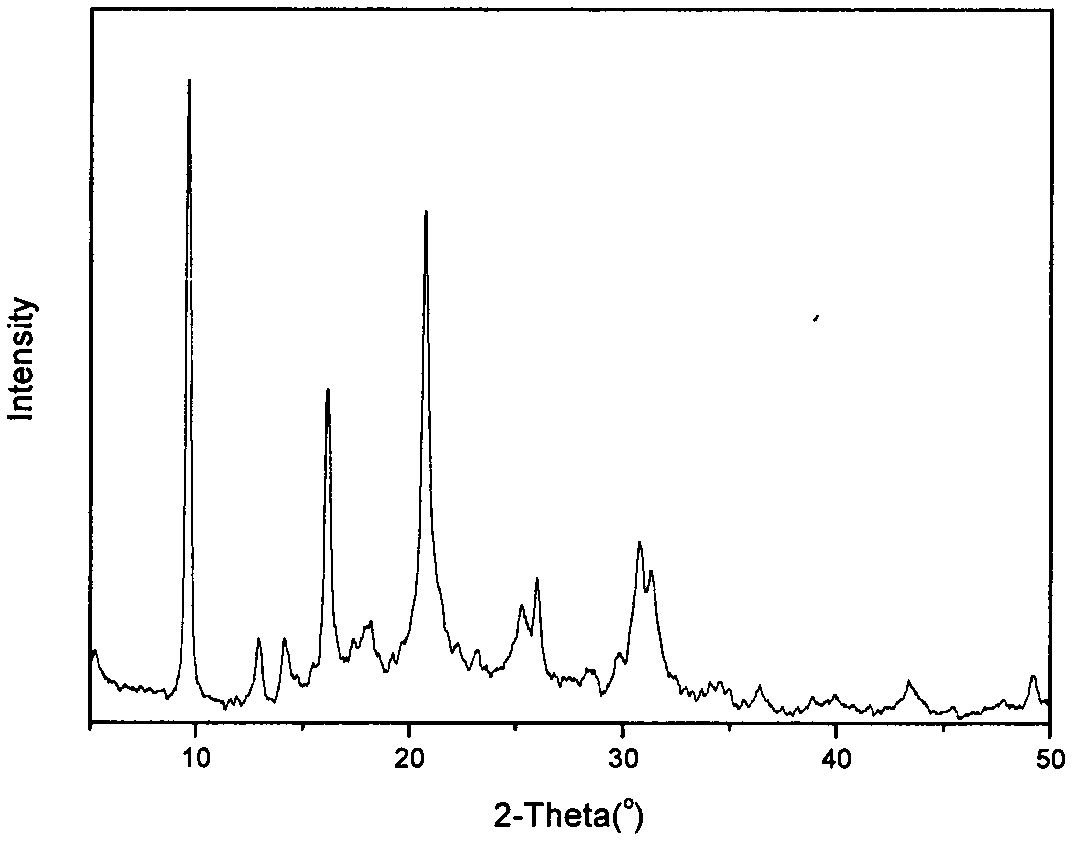

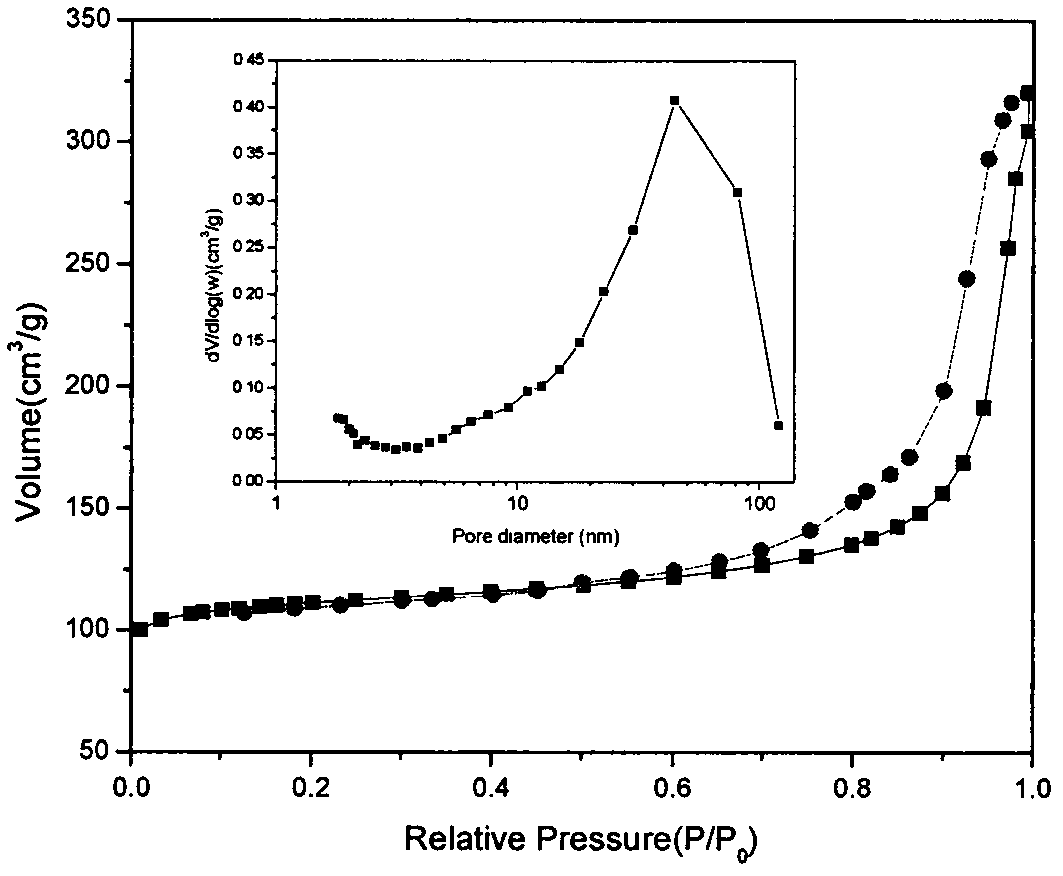

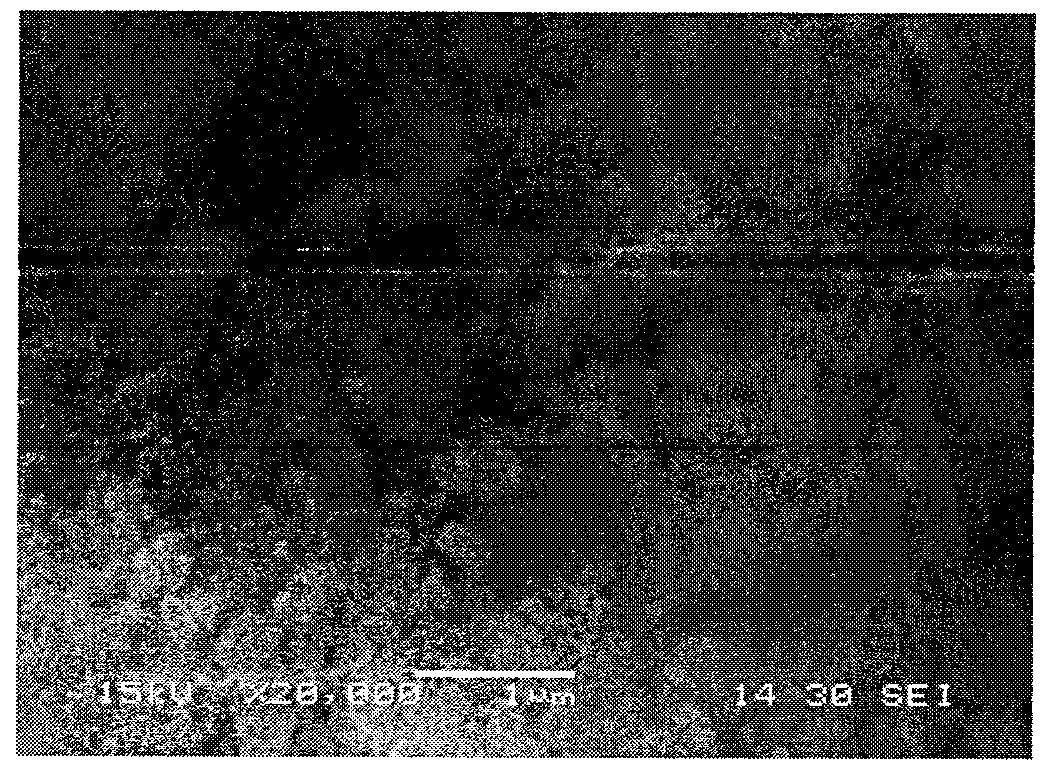

[0019] In the first step, silicon source: tetraethyl orthosilicate (TEOS), aluminum source: aluminum isopropoxide, organic template agent: tetraethylammonium hydroxide (TEAOH), mesoporous directing agent (HTS). In the fourth step, phosphorus source: orthophosphoric acid (H3PO4). Al2O3: P2O5: SiO2: HTS=1: 1: 0.6: 0.06, the solvent used is absolute ethanol. The crystallization time is 3 days, and the temperature is 200°C. This method yields SAPO-34 with hierarchical channels.

[0020] The accompanying drawings of this embodiment are as Figure 1 to Figure 3 shown.

Embodiment 2

[0022] Implementation process is except following difference, all the other are with embodiment 1.

[0023] The solvent used was toluene. This method yields SAPO-34 with hierarchical channels.

[0024] The accompanying drawings of this embodiment and Figure 1 to Figure 3 similar.

Embodiment 3

[0026] Implementation process is except following difference, all the other are with embodiment 1.

[0027] Aluminum source: aluminum sec-butoxide. This method yields SAPO-34 with hierarchical channels.

[0028] The accompanying drawings of this embodiment and Figure 1 to Figure 3 similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com