Laser grooving machining method of dry gas seal spiral groove

A processing method and dry gas sealing technology, which are applied in the processing field of spiral grooves, can solve problems such as no specific discussion, and achieve the effects of high speed, high precision and improved processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

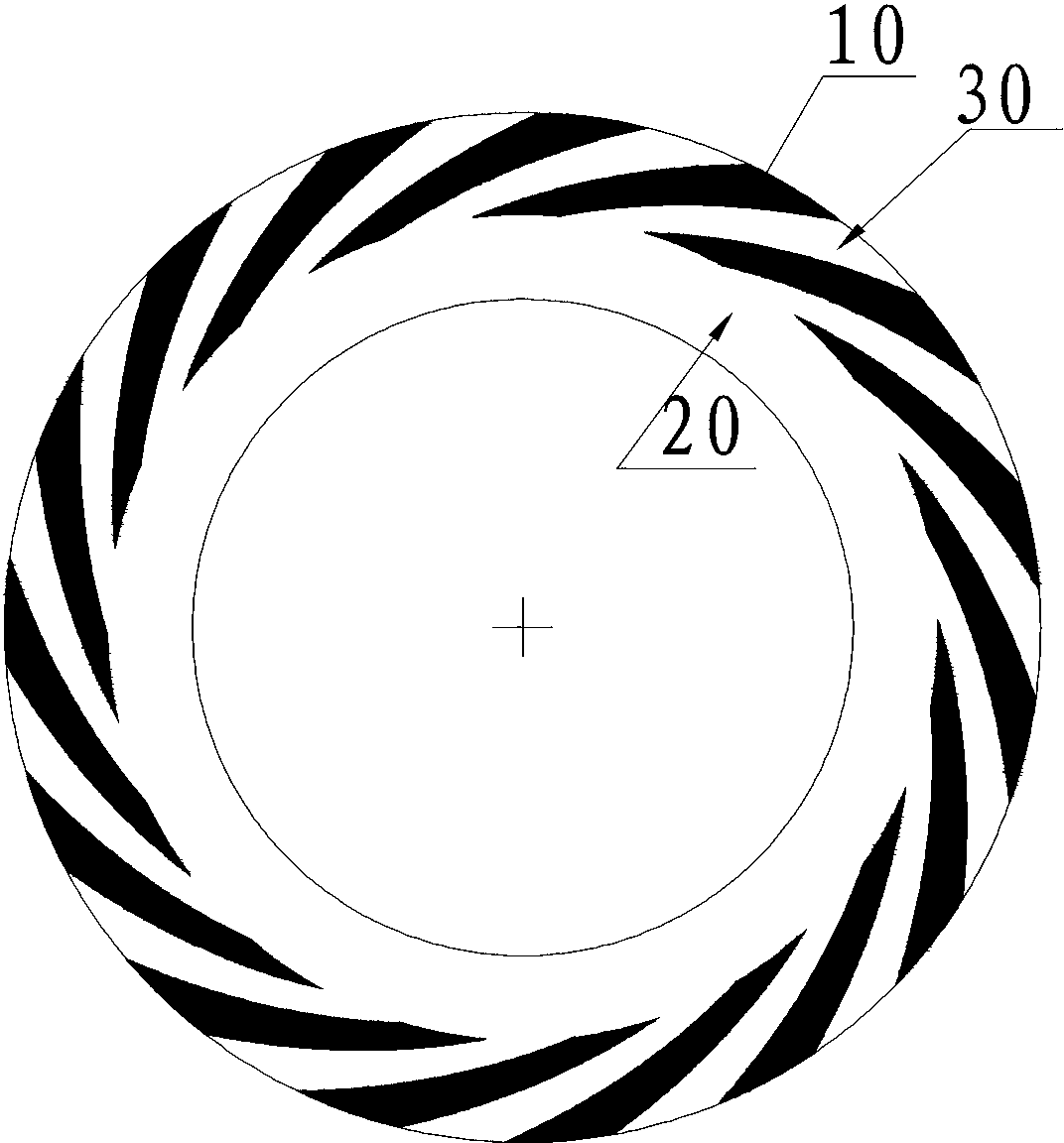

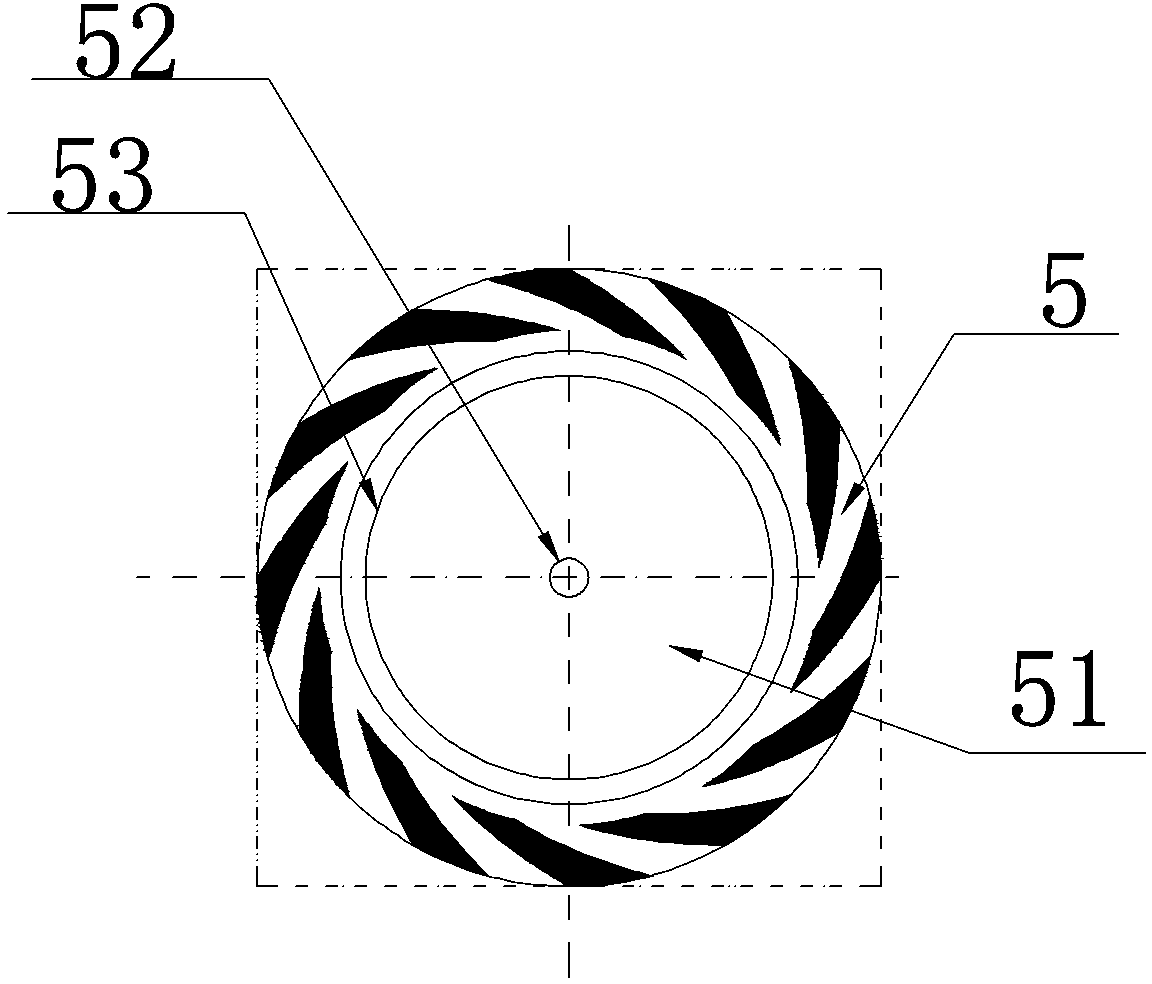

[0026] A laser groove processing method for dry gas sealing spiral grooves,

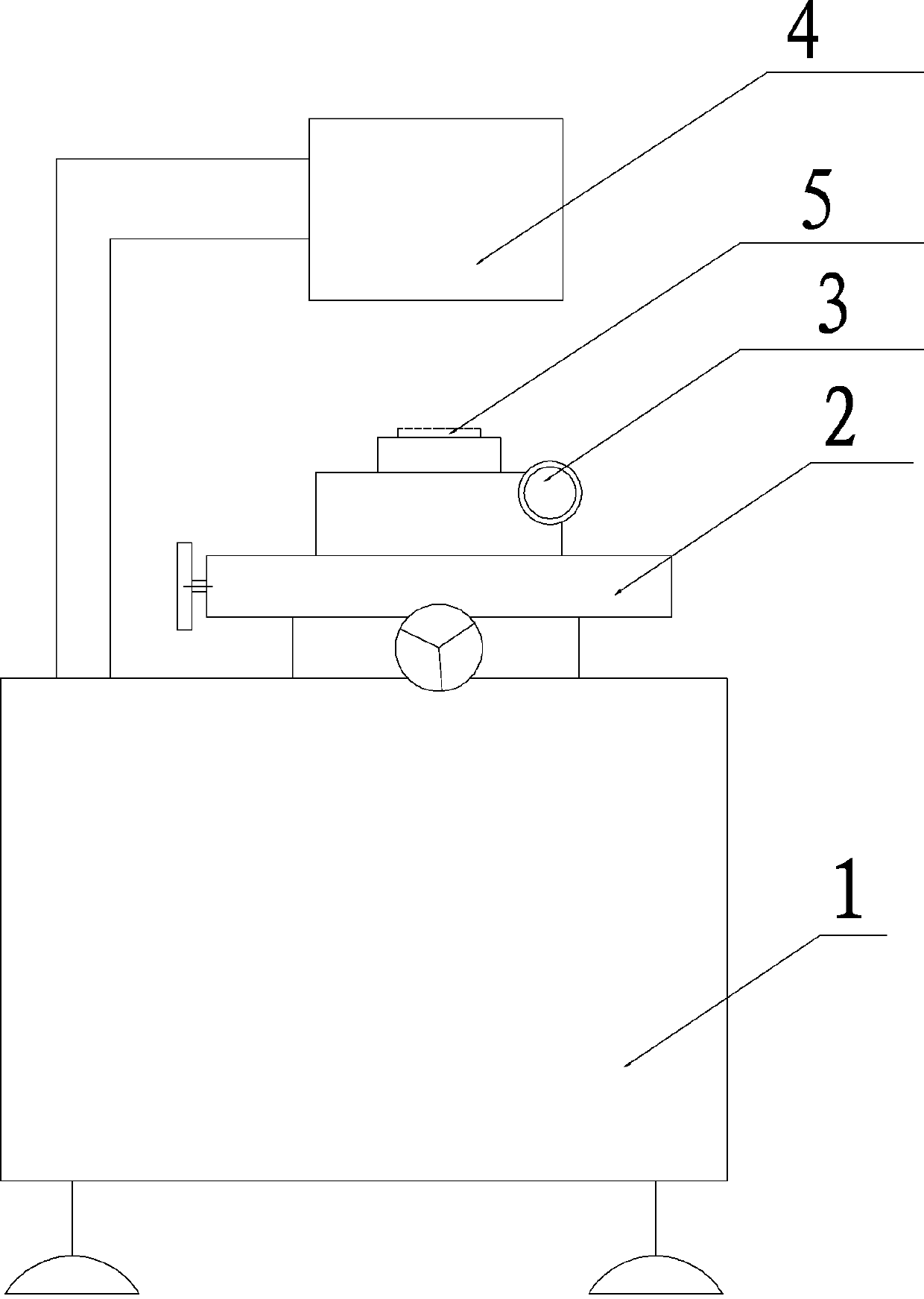

[0027] (1) Processing equipment

[0028] The core processing equipment for laser grooving is the 20W optical fiber marking machine manufactured by Shenzhen Han's Laser Technology Co., Ltd. The positioning accuracy of the light spot and the smoothness of the line can reach 0.001mm, which is especially suitable for repeated marking. For occasions with strict requirements on accuracy and fineness, the marking range is 100×100mm. An excessively large marking range will affect the power density of the spot and the marking accuracy. In the process of grooving, the engraved dynamic pressure grooves are required to be evenly distributed around the center of the ring, so it must be ensured that the center of the laser spot and the center of the ring are at the same point, which requires alignment b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com