Method for carrying out multi-purification treatment on tar-containing dust

A purification treatment, dust technology, applied in the direction of chemical instruments and methods, separation methods, coke ovens, etc., can solve the problems of inconvenient maintenance work for on-site operators, affect the normal update of the particle layer, shorten the service life of filter bags, etc., to ensure high efficiency Adsorption rate, helpful for on-site maintenance and smooth renewal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

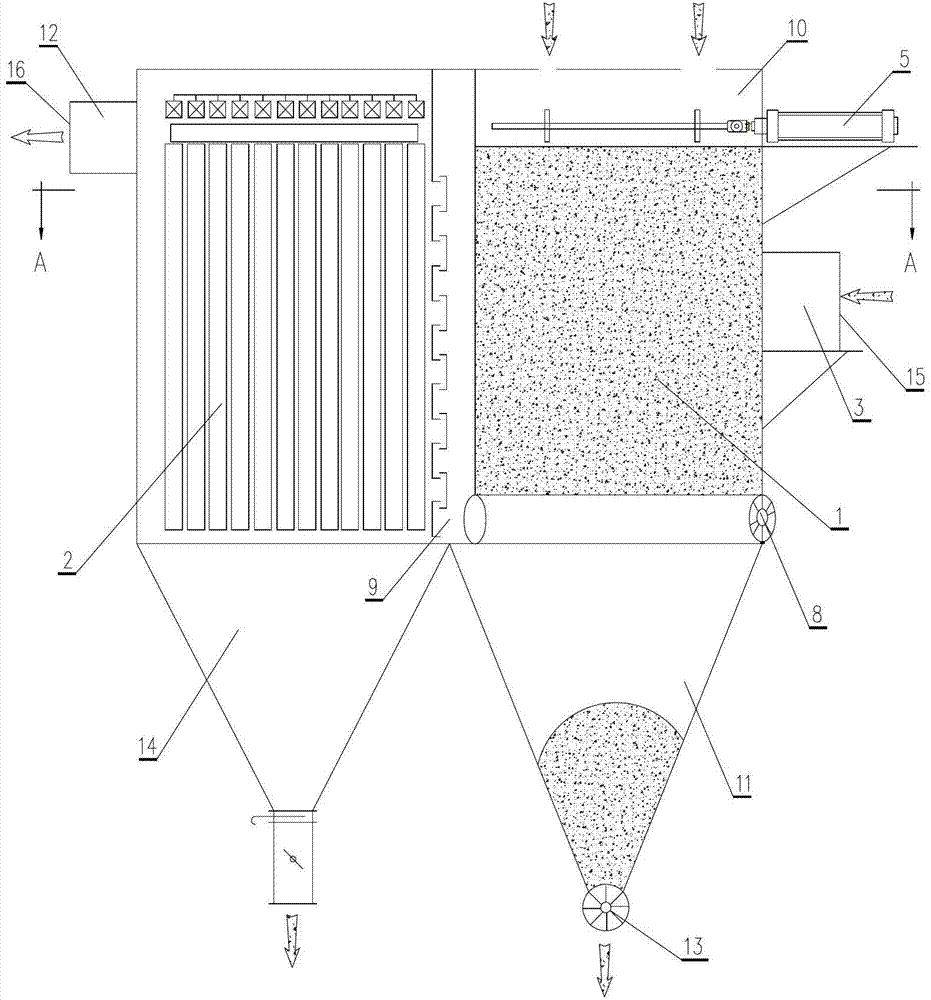

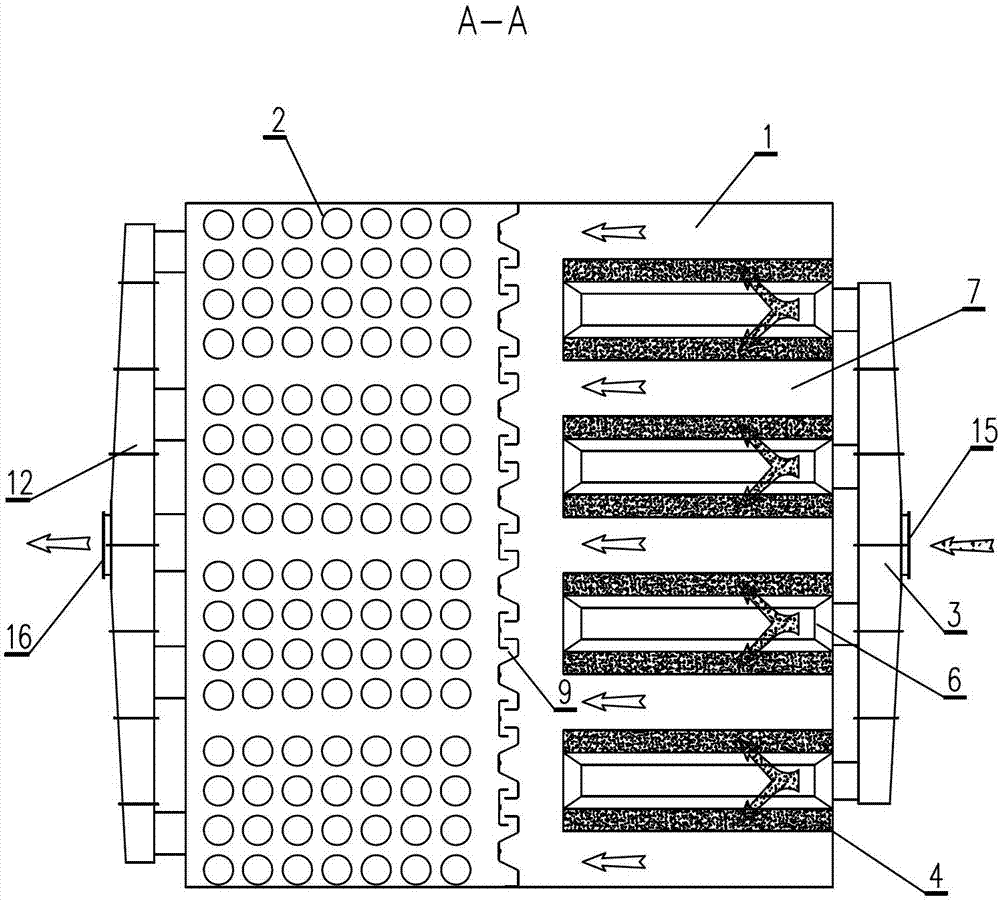

[0024] See figure 1 , figure 2 , a device for multiple purification treatment of tar-containing dust, including an adsorption purification unit 1, a terminal purification unit 2, an inlet manifold 3, a pressure equalization initial separation section 9, an outlet manifold 12, an ash tank 14, discharge and discharge Material system, between the adsorption purification unit 1 and the terminal purification unit 2, there is a pressure equalization primary separation section 9, the other side of the adsorption purification unit 1 is provided with an inlet manifold 3, and the other side of the terminal purification unit 2 is provided with an outlet manifold 12. The adsorption and purification unit 1 is equipped with a material distribution system, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com