Cooling slow release structure for crystals based on special-shaped groove

A crystal and groove technology, applied in the field of machinery, can solve the problems that the uniformity of the clamping torque is not easy to control, increase the deformation error of the crystal surface, and the additional stress of the crystal structure, so as to avoid different expansion deformation and reduce the error of the crystal surface shape , reducing the effect of additional deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

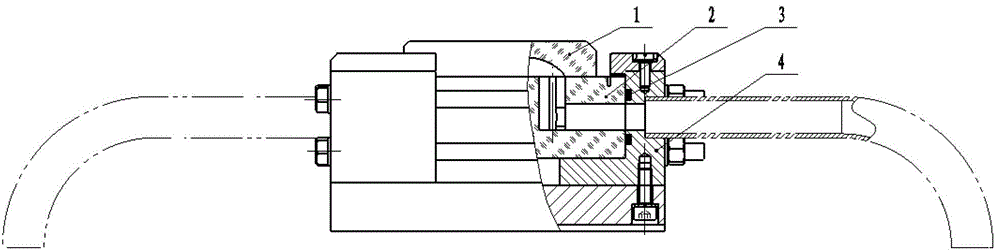

[0021] see figure 1 as well as figure 2 , the present invention provides a crystal heat slow-release structure based on a special-shaped groove, the structure includes a special-shaped groove diffraction crystal 1, a base crystal 2, a sealing ring 3, a stainless steel crystal holding seat 4, a pressure plate 5, a connecting rod 6 and The water pipe 7; the diffractive crystal is provided with a special-shaped groove of a certain size, the base crystal 2 is provided with a water inlet and outlet and a water collecting tank, and the two crystals are welded into a combined crystal by diffusion welding, which is the key technology of the present invention; After the crystal seat is welded, it is clamped on two stainless steel crystal holding seats, clamped by connecting rods, and pressed with a pressure plate; the water pipe is welded on the stainless steel base, and is connected to the base crystal through a sealing ring for sealing. The back of the diffractive crystal is a diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com