Method for manufacturing lead frame

A manufacturing method and technology for lead brackets, which are applied to electrical components, circuits, electric solid devices, etc., can solve the problems of fine dispersion of precipitates, unsatisfactory comprehensive properties of copper-iron alloys for lead brackets, and uneven structure of alloys, and achieve precipitation. The effect of fine phase dispersion, excellent hot workability and low alloy price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

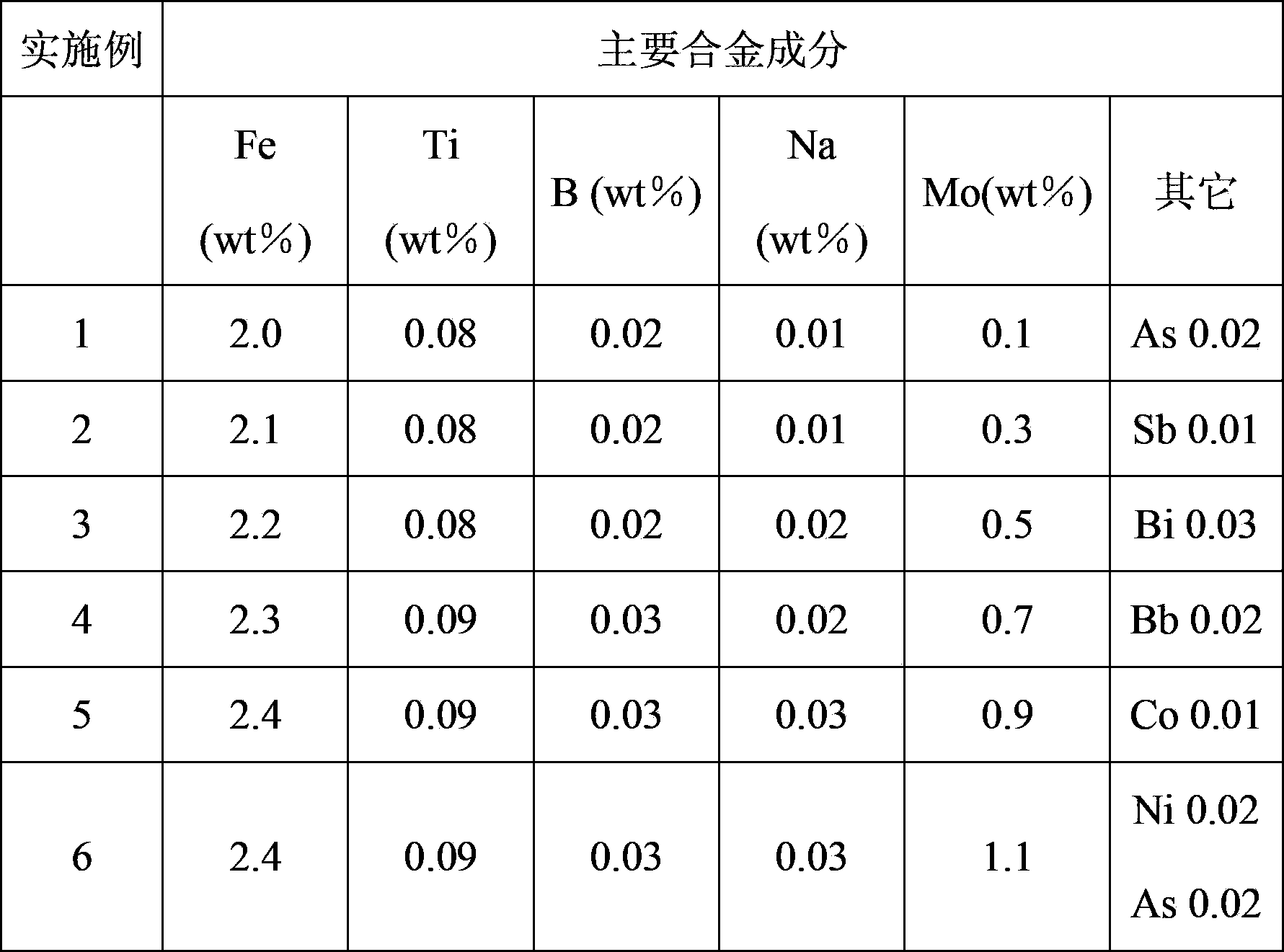

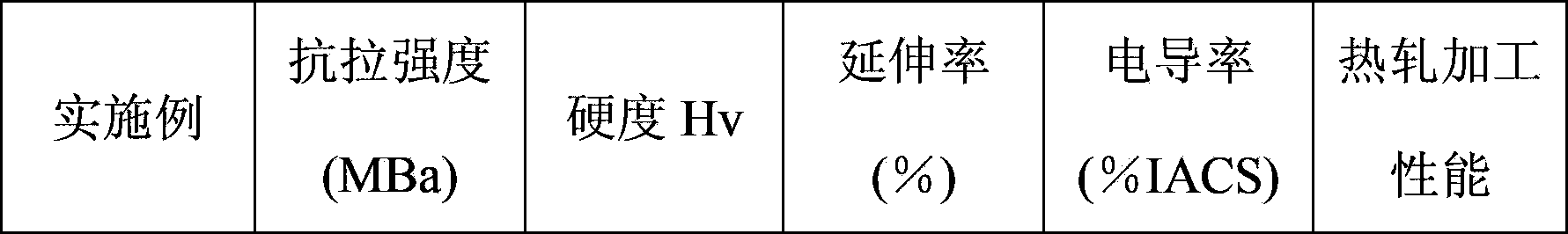

[0047] The copper-iron alloy No. 1~6 of composition (wt%) shown in table 1,

[0048] Table 1

[0049]

[0050] It is worth noting that during the melting process of the alloy, each element has different degrees of burning loss, and the burning loss rate is Fe: 1-2%, Ti: 1-3%, B: 2-5%, Na: 20 ~30%, Mo: 30~50%; it should be supplemented during the batching process. At the beginning of smelting, add electrolytic copper and copper-iron intermediate alloy first, start heating, and after it melts, add 1 / 3 of copper-boron intermediate alloy and keep it warm for 1 to 3 minutes; then add titanium, sodium and rare earth, and keep it warm for 3 minutes after melting ~5min, then add the remaining 2 / 3 of the copper-boron intermediate alloy, and cast it with heat preservation for 10min after full melting; use a small vertical semi-continuous casting machine to cast a billet of 70×180×1000 (mm), and use the billet mold for one cooling and Water shower is used for secondary cooling, so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com