High fire retardation unsaturated polyester molding compound

An unsaturated, molding compound technology, used in the field of thermosetting molding compounds, can solve the problem of difficult to meet the requirements of flame retardancy, and achieve the effects of excellent flame retardancy, good strength and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

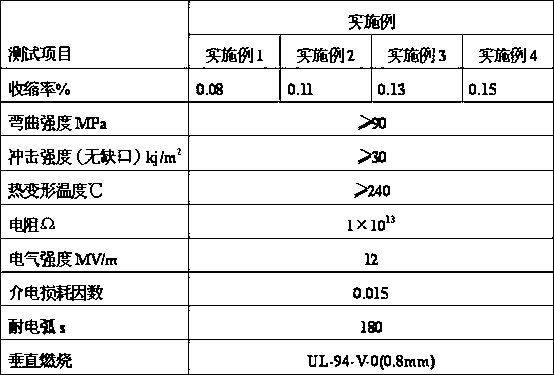

Examples

Embodiment 1

[0025] 41 parts of bisphenol A type unsaturated polyester resin with resin solid content of 60-65%;

[0026] 30 parts of polymethyl methacrylate type low-shrinkage additives with a solid content of 38-40%;

[0027] 6 parts of triallyl isocyanurate;

[0028] 0.8 parts of tert-butyl peroxybenzoate;

[0029] P-phenol 0.008 part;

[0030] 0.16 parts of magnesium oxide;

[0031] 130 parts of aluminum hydroxide;

[0032] Mixture of melamine urate and calcium carbonate,

[0033] Wherein, the mass percent of melamine urate is 55% 10 parts;

[0034] 8 parts of flame retardant masterbatch;

[0035] Zinc stearate 3.2 parts;

[0036] 28 parts of alkali-free glass fibers with a length of 3mm.

Embodiment 2

[0038] Resin solid content is 46 parts of isophthalic unsaturated polyester resins of 60-65%;

[0039] 28 parts of polymethyl methacrylate type low-shrinkage additives with a solid content of 38-40%;

[0040] 8 parts of triallyl isocyanurate;

[0041] 0.65 parts of tert-butyl peroxybenzoate;

[0042] 0.006 parts of p-phenol;

[0043] 0.5 parts of magnesium oxide;

[0044] 160 parts of aluminum hydroxide;

[0045] Mixture of melamine urate and calcium carbonate,

[0046] Wherein, the mass percent of melamine urate is 55% 15 parts;

[0047] 5 parts of flame retardant masterbatch;

[0048] Zinc stearate 2.4 parts;

[0049] 32 parts of non-alkali glass fiber with a length of 3mm.

Embodiment 3

[0051] Resin solid content is 43 parts of the bisphenol A type unsaturated polyester resin of 60-65%;

[0052] 32.6 parts of polymethylmethacrylate type low-shrinkage additives with a solid content of 38-40%;

[0053] 7 parts of triallyl isocyanurate;

[0054] 0.9 parts of tert-butyl peroxybenzoate;

[0055] P-phenol 0.009 parts;

[0056] 0.3 parts of magnesium oxide;

[0057] 140 parts of aluminum hydroxide;

[0058] Mixture of melamine urate and calcium carbonate,

[0059] Wherein, the mass percent of melamine urate is 55% 12 parts;

[0060] 7 parts of flame retardant masterbatch;

[0061] Zinc stearate 2.8 parts;

[0062] 37 parts of alkali-free glass fibers with a length of 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com