Preparation method of low-leakage current Bi0.92Tb0.08Fe(1-x)CrxO3 film

A technology of bi0.92tb0.08fe1-xcrxo3 and leakage current, applied in the field of functional materials, can solve the problems of limited application, achieve the effects of improving multiferroic performance, precise and controllable chemical composition, and reducing leakage conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1: Add Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 ·9H 2 O, Tb(NO 3 ) 3 ·6H 2 O and Cr (NO 3 ) 3 ·9H 2 O mole ratio 0.97:0.99:0.08:0.01 is dissolved in the mixture of ethylene glycol methyl ether and acetic anhydride to form a mixed solution, and ethanolamine is added to the mixed solution to adjust the viscosity and the degree of complexation to obtain stable BiFeO 3 Precursor fluid, among them, BiFeO 3 The concentration of metal ions in the precursor solution is 0.3 mol / L, and the volume ratio of ethylene glycol methyl ether, acetic anhydride and ethanolamine is 3.5:1:0.2.

[0022] Step 2: Spin-coating and annealing layer by layer at 550°C for 5-l0min, and then natural cooling to room temperature, to obtain Tb and Cr co-doped crystalline Bi 0.92 Tb 0.08 Fe 0.99 Cr 0.01 O 3 film.

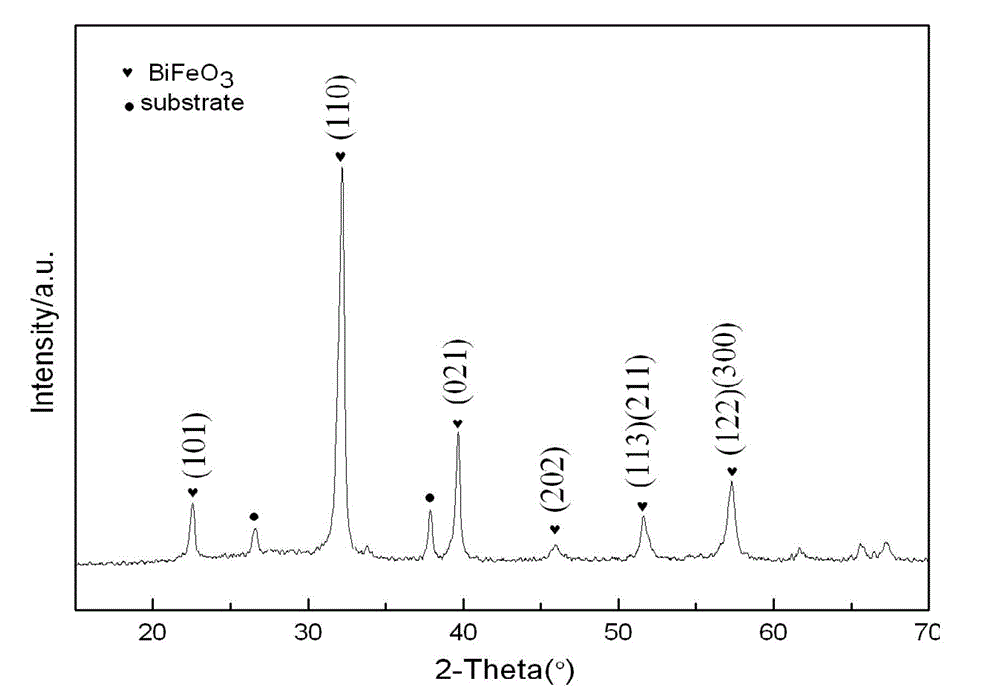

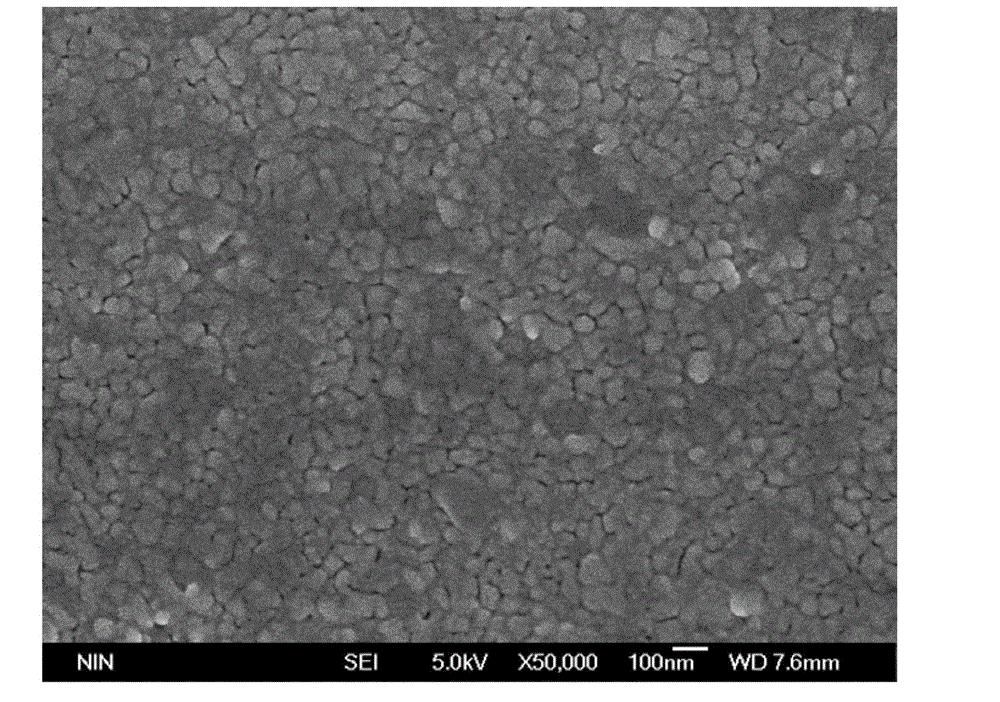

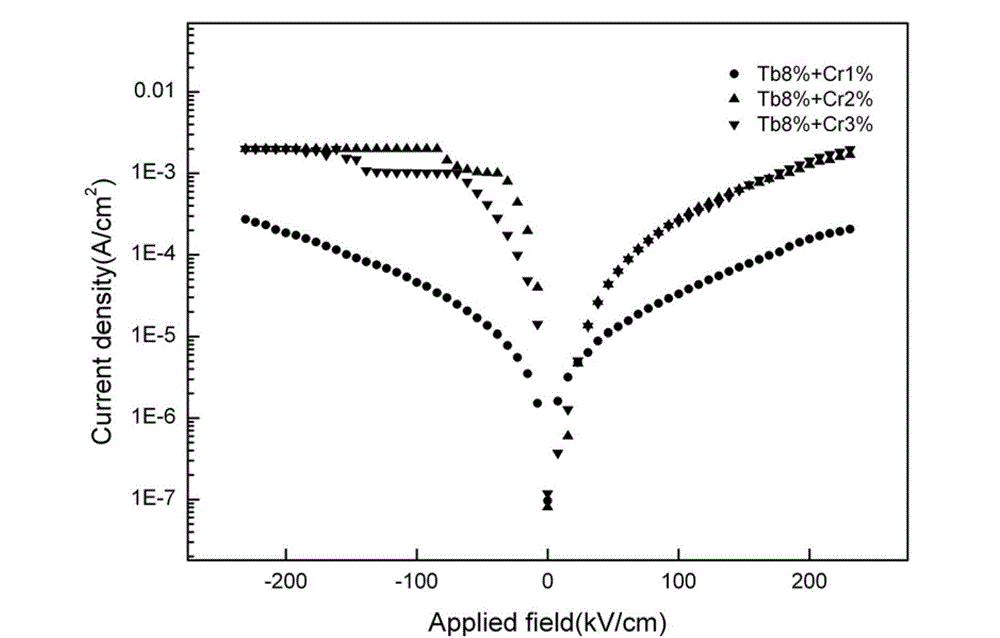

[0023] With Tb and Cr doped into BiFeO at the same time 3 , Thus fictional BiFeO 3 Oxygen vacancies in the film due to changes in the valence state of Fe during heat treatment. At the same time Tb and C...

Embodiment 2

[0025] Step 1: Add Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 ·9H 2 O, Tb(NO 3 ) 3 ·6H 2 O and Cr (NO 3 ) 3 ·9H 2 O mole ratio 0.97: 0.98: 0.08: 0.02 is dissolved in the mixture of ethylene glycol methyl ether and acetic anhydride to form a mixed solution, and ethanolamine is added to the mixed solution to adjust the viscosity and the degree of complexation to obtain a stable BiFeO 3 Precursor fluid, among them, BiFeO 3 The concentration of metal ions in the precursor solution is 0.3 mol / L, and the volume ratio of ethylene glycol methyl ether, acetic anhydride and ethanolamine is 3.5:1:0.2.

[0026] Step 2: Spin-coating and annealing layer by layer at 550°C for 5-10min, and then natural cooling to room temperature, to obtain Tb and Cr co-doped crystalline Bi 0.92 Tb 0.08 Fe 0.98 Cr 0.02 O 3 film.

[0027] With Tb and Cr doped into BiFeO at the same time 3 , Thus fictional BiFeO 3 Oxygen vacancies in the film due to changes in the valence state of Fe during heat treatment. At the same time Tb ...

Embodiment 3

[0029] Step 1: Add Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 ·9H 2 O, Tb(NO 3 ) 3 ·6H 2 O and Cr (NO 3 ) 3 ·9H 2 O molar ratio of 0.97:0.97:0.08:0.03 is dissolved in the mixture of ethylene glycol methyl ether and acetic anhydride to form a mixed solution. Ethanolamine is added to the mixed solution to adjust the viscosity and the degree of complexation to obtain stable BiFeO 3 Precursor fluid, among them, BiFeO 3 The concentration of metal ions in the precursor solution is 0.3 mol / L, and the volume ratio of ethylene glycol methyl ether, acetic anhydride and ethanolamine is 3.5:1:0.2.

[0030] Step 2: Spin-coating and annealing layer by layer at 550°C for 5-10min, and then natural cooling to room temperature, to obtain Tb and Cr co-doped crystalline Bi 0.92 Tb 0.08 Fe 0.97 Cr 0.03 O 3 film.

[0031] With Tb and Cr doped into BiFeO at the same time 3 , Thus fictional BiFeO 3 Oxygen vacancies in the film due to changes in the valence state of Fe during heat treatment. At the same time Tb and C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com