New method for preparing semiconductor nano-crystals containing tellurium, selenium or sulfur

A nanocrystal and semiconductor technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of expensive, toxic, flammable and explosive, and achieve the effect of easy operation, good repeatability and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 CdTe nanocrystal

[0028] Add 4 mmol Te powder to 20 g dioctylphosphine oxide (di-n-octylphosphine oxide, DOPO) and heat to 320 °C under nitrogen atmosphere until Te is completely dissolved to obtain a light yellow solution, which is the Te precursor, and cool it for later use.

[0029] Mix 0.2mmol cadmium oleate and 6g octadecene into a 25mL three-neck bottle, and heat to 240°C (180-350°C is acceptable) under nitrogen atmosphere to obtain a clear and uniform solution, namely the cadmium precursor.

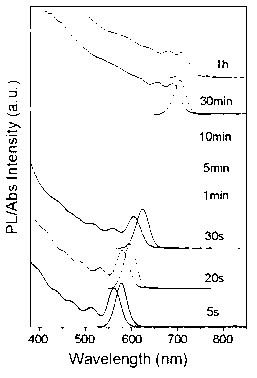

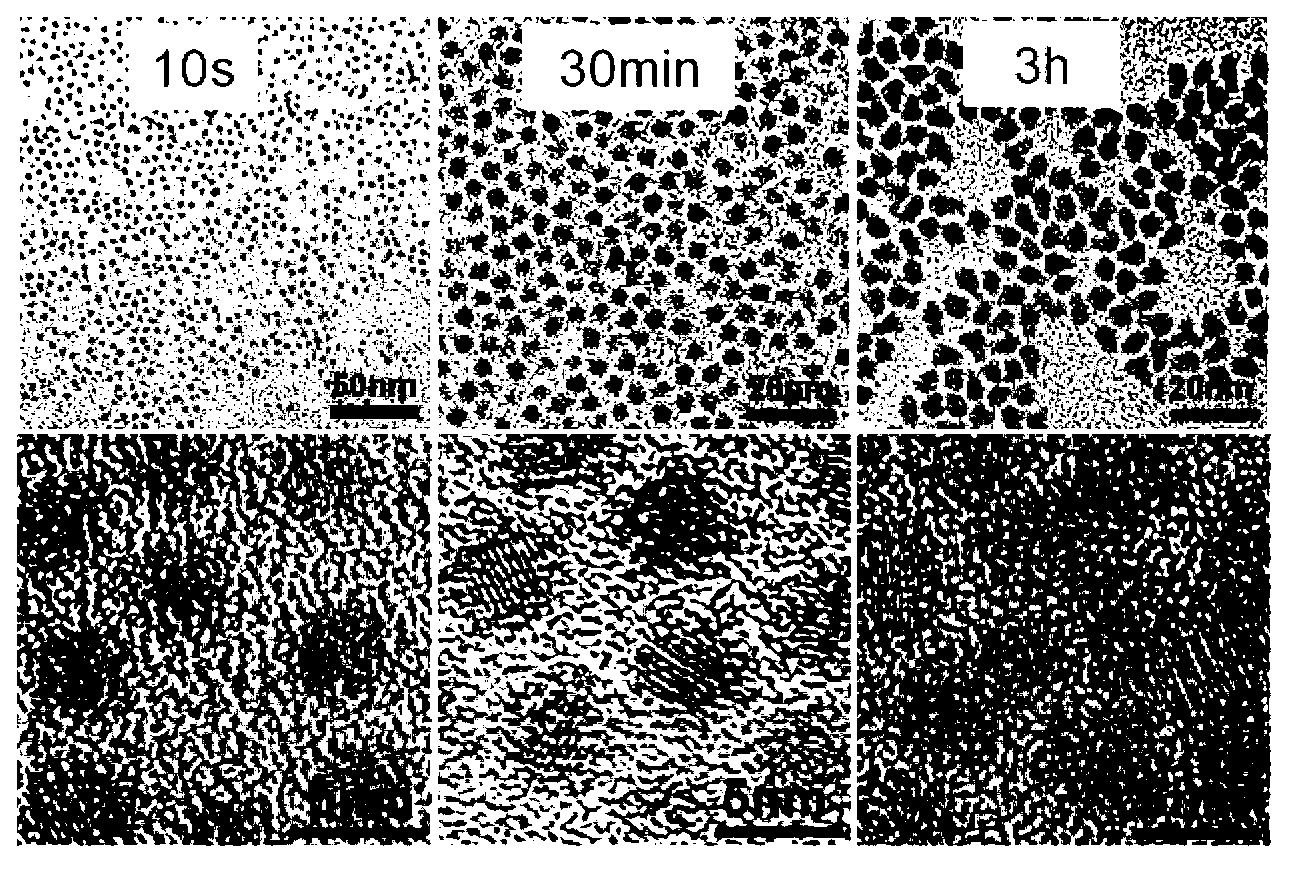

[0030] Take 1g of Te precursor solution and inject it into the Cd solution at 280°C, and take samples for observation at different times. After reacting for 3 hours, cool down, add acetone to precipitate, and centrifuge to obtain CdTe nanocrystals. The fluorescence absorption spectra of CdTe nanocrystals obtained by sampling and testing at different times are as follows: figure 1 As shown, the TEM and HRTEM of CdTe nanocrystals are as figu...

Embodiment 2

[0031] The preparation of embodiment 2 ZnTe nanocrystals

[0032] 2mmol Te powder was added to 10g di-n-octylphosphinic acid (DOPA) and heated to 350°C under nitrogen atmosphere until Te was completely dissolved to obtain a light yellow solution, namely Te precursor, which was cooled for later use.

[0033] 0.4 mmol of zinc acetylacetonate and 6 g of octadecene were mixed into a 25 mL three-neck bottle, and heated to 240 °C (180-350 °C is acceptable) under nitrogen atmosphere to obtain a clear and homogeneous solution that is the zinc precursor.

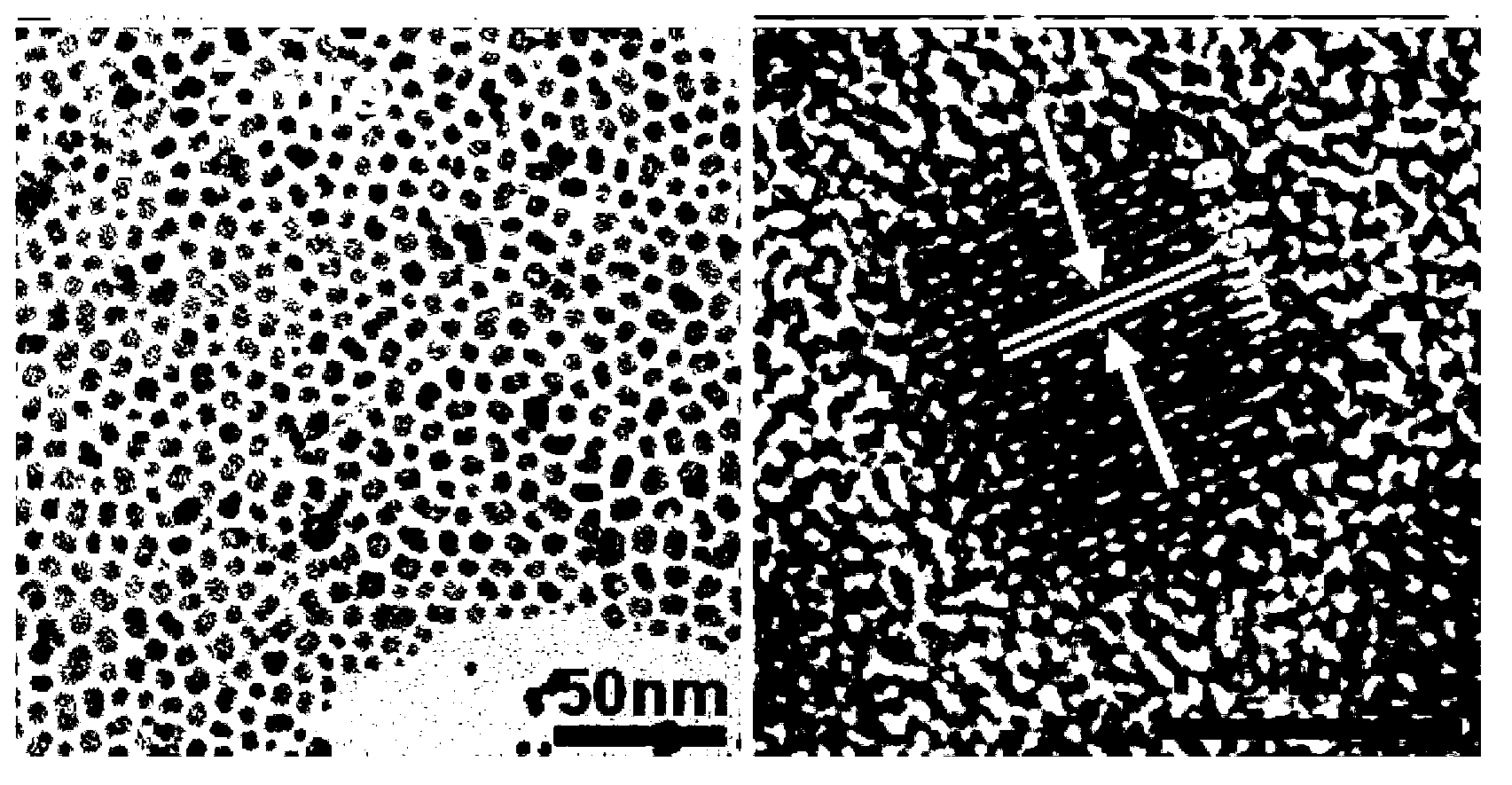

[0034] Take 2g of Te precursor solution and inject it into the Zn solution at 310°C, and take samples for observation at different times. After reacting for 3 hours, cool down, add acetone to precipitate, and centrifuge to obtain ZnTe nanocrystals. TEM as image 3 As shown, the XRD pattern is as Figure 7 shown.

Embodiment 3

[0035] Example 3 Preparation of CuTe nanocrystals

[0036] 2mmol Te powder was added to 20g DOPO and heated to 320°C under nitrogen atmosphere until Te was completely dissolved to obtain a light yellow solution, namely Te precursor, which was cooled for later use.

[0037] Mix 0.2mmol copper stearate and 6g octadecene into a 25mL three-neck bottle, and heat to 240°C (180-350°C is acceptable) under nitrogen atmosphere to obtain a clear and homogeneous solution that is the copper precursor.

[0038] Take 2g of Te precursor solution and inject it into the Cu solution at 310°C, and take samples for observation at different times. After reacting for 3 hours, cool down, add acetone to precipitate, and centrifuge to obtain CuTe nanocrystals. TEM such as Figure 4 As shown, the XRD pattern is as Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com