System for laser focus positioning and method for positioning material on laser focus point

A positioning system and optical material technology, applied in the field of material surface positioning, can solve problems such as the inability to determine whether the material surface is positioned in the center of the focal area, the inability to directly track and observe the distance from the material surface to the focal point, and the difficulty in controlling the positioning error. The effect of simplicity, elimination of positioning differences, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

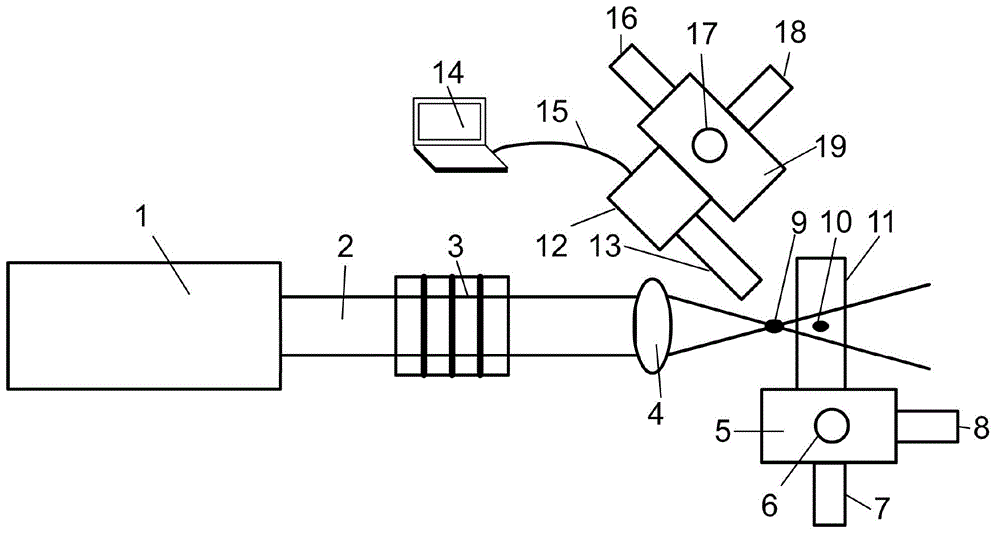

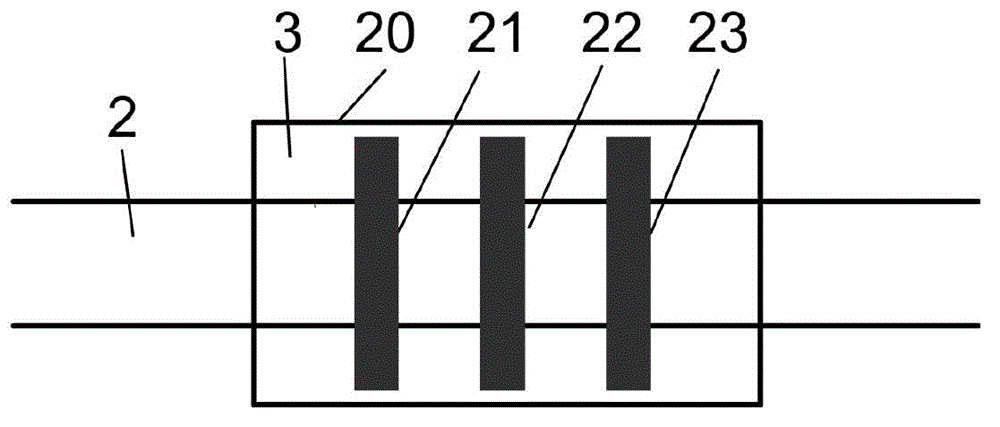

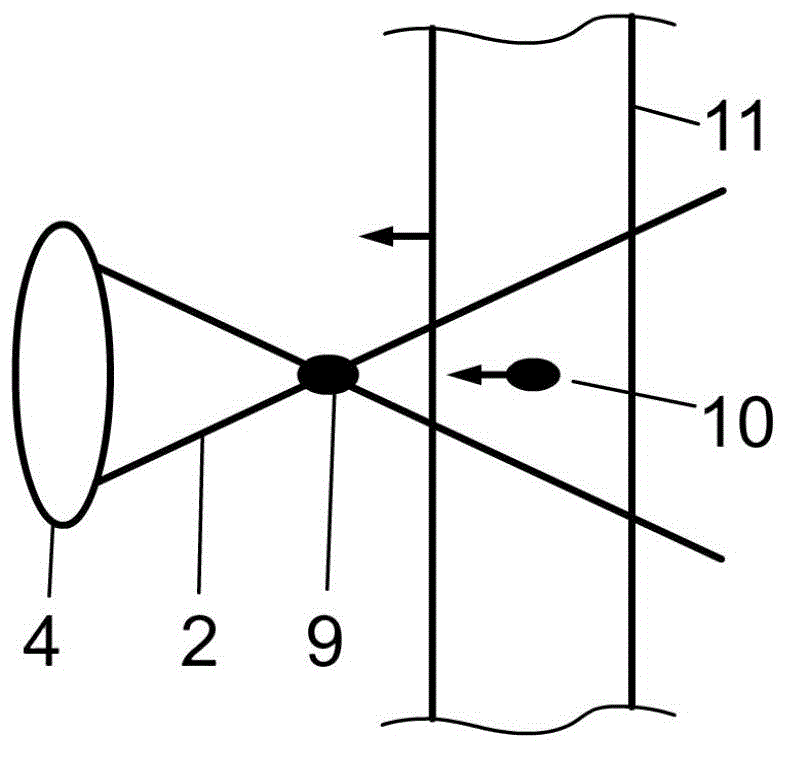

[0033] a kind of like figure 1 The laser focus positioning system of the present invention shown includes a laser device 1, an adjustable laser attenuation sheet system 3, a converging lens 4, a material translation device 5 and a CCD microscopic imaging system, and the laser beam 2 output by the laser device 1 passes through the laser attenuation sheet first The system 3 is parallel to the optical axis of the converging lens 4 and is vertically incident on the converging lens 4 . After being focused by the converging lens 4 , the output beam is incident on the surface of the optical material 11 to be measured or to be processed clamped on the material translation device 5 . The output wavelength of the laser 1 of the present embodiment is 800nm, the maximum output average power is 5W, and the beam quality factor M 2 is 1.2. The converging lens 4 of this embodiment is a short focal length focusing lens, and its focal length is 10mm. Such as figure 2 As shown, the adjustabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com