Method for optimizing aluminum/steel metal inert-gas (MIG) soldered joint through tungsten inert gas (TIG) voltaic arc cooperating with heating

A technology for brazing joints and optimizing aluminum, which is used in arc welding equipment, welding equipment, metal processing equipment, etc. to improve mechanical properties, improve work efficiency, and increase the effect of pinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

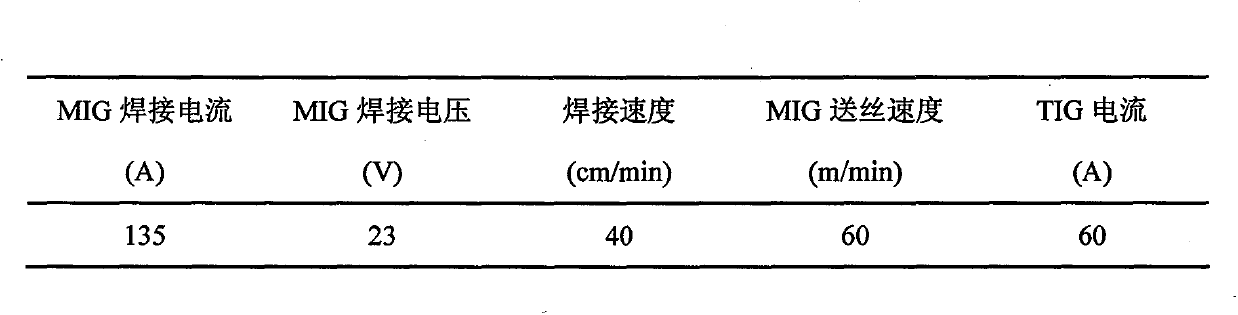

[0015] A method for optimizing aluminum / steel MIG brazing joints through TIG electric arc cooperative heating, characterized in that: the method steps are as follows:

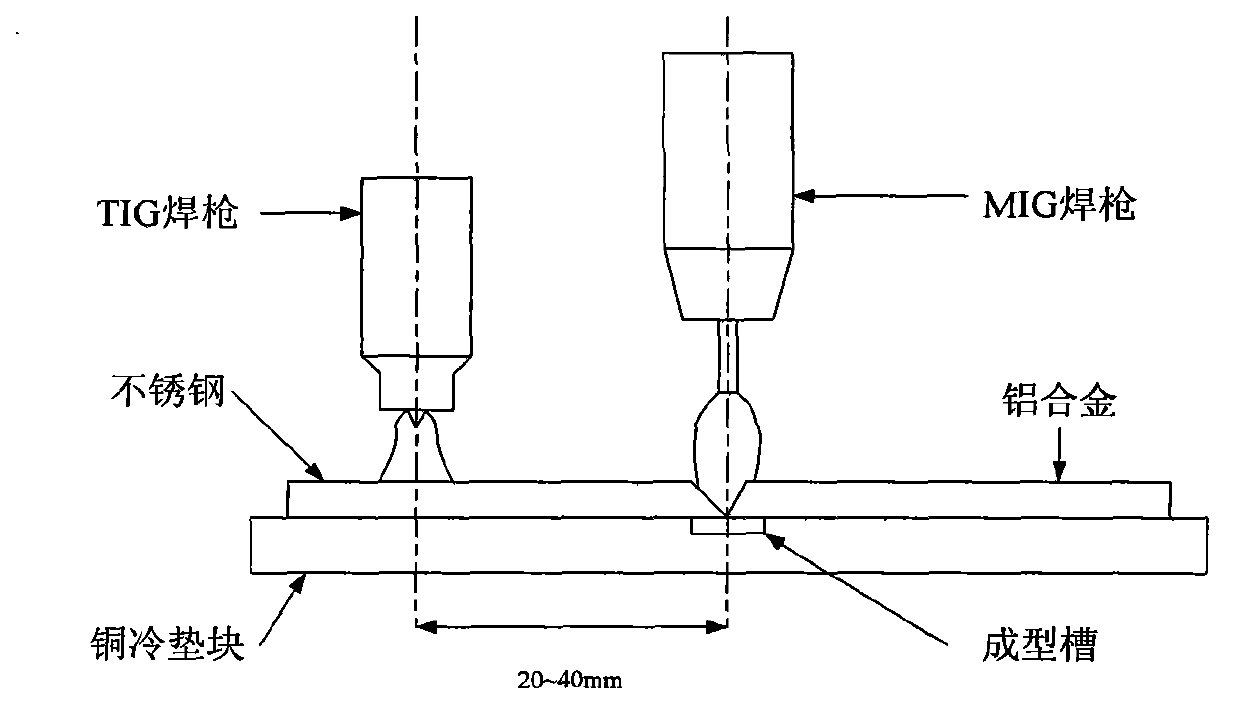

[0016] (1) Set the TIG welding torch on the upper surface of the steel substrate next to the MIG welding torch, the MIG welding torch and the TIG welding torch are parallel to each other, and the distance between the TIG arc and the MIG arc is 20-40mm;

[0017] (2) Open a V-shaped groove on the connection between the equal-thickness aluminum plate and the steel plate. The groove angle on the side of the steel base metal is 40°, and the groove angle on the side of the aluminum base metal is 30°;

[0018] (3) Use acetone to wipe the grooves and surroundings of the aluminum plate and steel plate to remove oil and impurities, mix liquid binder and potassium fluoroaluminate brazing flux 1:1 to form a paste, and apply the mixed paste on the steel plate with a wooden brush Groove surface, dry with a hair dryer to be w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com