Production process for improving titer of swine fever live vaccine product

A swine fever live vaccine and production technology technology, which is applied in the field of production technology for improving the titer of swine fever live vaccine products, can solve the problems of low stock quantity, increase the number of heads, and difficulty in production, so as to improve the titer and quality, prolong the The effect of shelf life and drug price increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 3) Preparation of swine fever live vaccine:

[0032] a. Inoculation: Make a 20-50 times diluted emulsion with a special protective agent for swine fever virus for the production of virus seeds, and inject 1 mL into each rabbit's ear vein;

[0033] b. Temperature measurement: the operation is the same as b in step 2);

[0034] c. Harvest of semi-finished products: select rabbits with stereotyped heat or light heat reaction, dissect them within 24 hours after the body temperature drops, and collect spleen and lymph with aseptic operation to obtain semi-finished products;

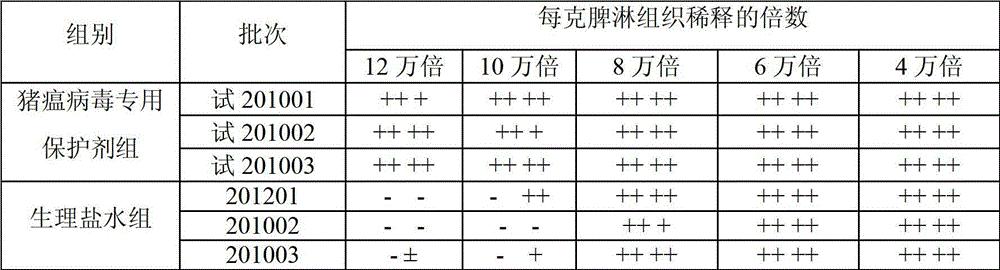

[0035] d. Preservation of semi-finished products: After adding 200-300mL of special protective agent for spleen-leaching tissue per kilogram to the semi-finished products, store them in a freezer below -15°C; the storage time should not exceed 60 days;

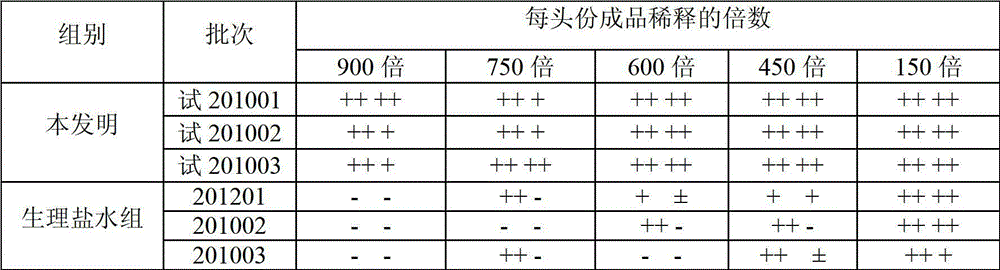

[0036] 4) Mixing seedlings, packaging and freeze-drying: under aseptic operation, weigh and cut the semi-finished products into pieces, add 5% sucrose...

Embodiment 1

[0042] A kind of production technology that improves the product potency of swine fever live vaccine, it comprises the following steps:

[0043] 1) Selection of rabbits: select healthy rabbits with a weight of 1.5-3.0kg, measure and observe the temperature for more than 3 days before inoculation, and the body temperature needs to be normal;

[0044] 2) Propagation of poisonous species:

[0045] a. Inoculation: make a 20-fold diluted emulsion with a special protective agent for CSF virus, and inject 0.5 mL into each rabbit's ear vein;

[0046] b. Temperature measurement: 24 hours after the rabbit was inoculated, the body temperature was measured every 6 hours;

[0047] c. Harvesting of production virus seeds: select the rabbits with stereotyped heat response, dissect them within 24 hours after the body temperature drops, take the spleen by aseptic operation, and freeze the spleen at -15°C as the production virus seeds;

[0048] d. Identification of production poisonous specie...

Embodiment 2

[0069] A kind of production technology that improves the product potency of swine fever live vaccine, it comprises the following steps:

[0070] 1) Selection of rabbits: select healthy rabbits with a weight of 1.5-3.0kg, measure and observe the temperature for more than 3 days before inoculation, and the body temperature needs to be normal;

[0071] 2) Propagation of poisonous species:

[0072] a. Inoculation: make a 50-fold diluted emulsion with a special protective agent for CSF virus, and inject 2 mL into each rabbit's ear vein;

[0073] b. Temperature measurement: 24 hours after the rabbit was inoculated, the body temperature was measured every 8 hours;

[0074] c. Harvesting of production virus seeds: select the rabbits with stereotyped heat response, dissect them within 24 hours after the body temperature drops, take the spleen by aseptic operation, and freeze the spleen at -15°C as the production virus seeds;

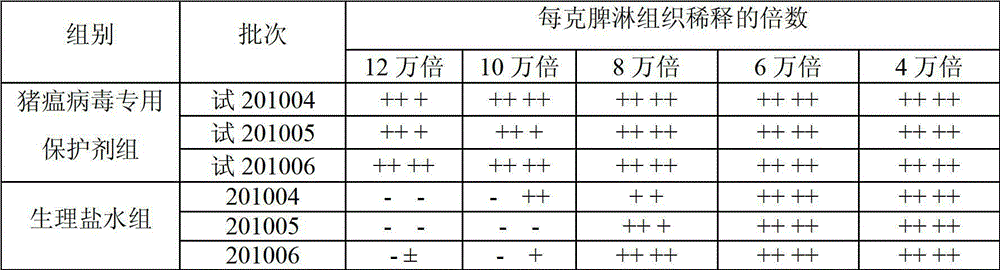

[0075] d. Identification of production poisonous species:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com