Nano yarn reinforcement electrostatic spinning fiber texture engineering scaffold and method for producing same

A technology of fibrous tissue and nanofibers, applied in fiber processing, textiles and papermaking, medical science, etc., can solve the problems of destroying the overall structure of nanofiber scaffolds, tensile mechanical strength limitations, tissue regeneration barriers, etc., and achieve broad application prospects. Easy to operate, and the effect of improving the tensile breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The nanofiber tissue engineering scaffold reinforced by the nano-yarns of the present invention is prepared according to the aforementioned method, including the preparation of spinning solution, the setting of electrospinning parameters, the preparation of nano-yarns, the collection of nano-yarns and nano-fibers, the rotation of the receiving device and the Vacuum drying and other steps, using the following process conditions:

[0036] (1) Dissolving L-polylactic acid in hexafluoroisopropanol solvent and stirring overnight to obtain a spinning solution with a concentration of 0.075 g / ml.

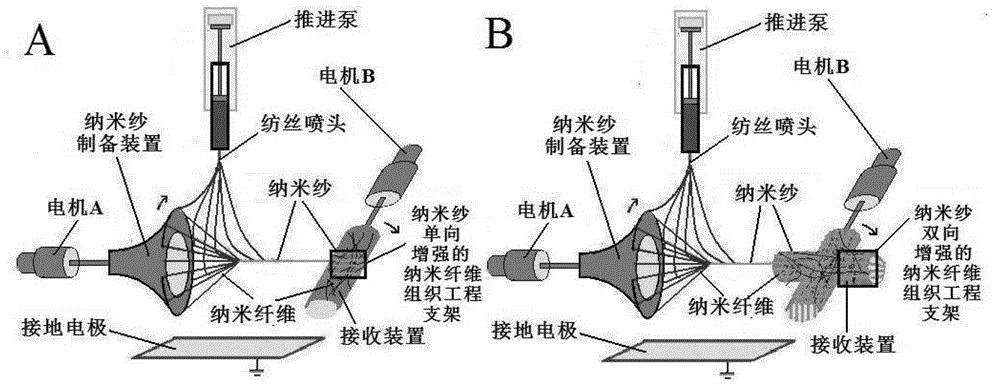

[0037] (2) Inject the spinning solution into the propelling pump, and follow the instructions figure 1 (A) A preparation device was set up, using a funnel-shaped device with an opening diameter of 9 cm as the nano-yarn preparation device, and a cylindrical receiving device with a diameter of 5 cm to collect the nano-yarns and nanofibers. A voltage of 12 kV was applied to the spinner...

Embodiment 2

[0042] The nanofiber tissue engineering scaffold reinforced by the nano-yarns of the present invention is prepared according to the aforementioned method, including the preparation of spinning solution, the setting of electrospinning parameters, the preparation of nano-yarns, the collection of nano-yarns and nano-fibers, the rotation of the receiving device and the Vacuum drying and other steps, using the following process conditions:

[0043] (1) Dissolving L-polylactic acid in hexafluoroisopropanol solvent and stirring overnight to obtain a spinning solution with a concentration of 0.08 g / ml.

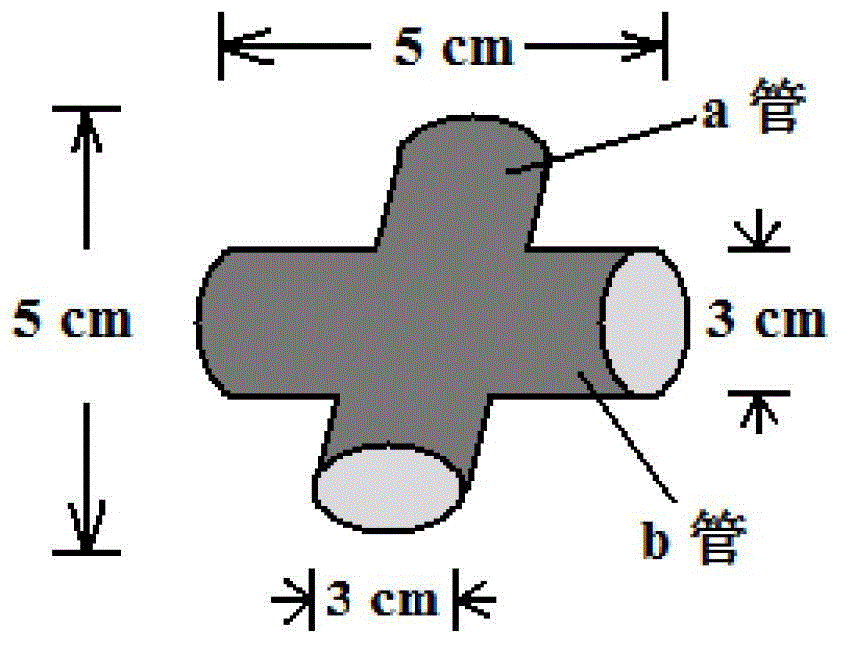

[0044] (2) Inject the spinning solution into the propelling pump, and follow the instructions figure 1 (B) Set up the preparation device, use a funnel-shaped device with an opening diameter of 9 cm as the nano-yarn preparation device, and rotate the "roller" in a "cross" shape (as shown in the appendix). figure 2 ) as receivers for nanoyarns and nanofibers. A voltage of 12 kV was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com