Hot steam energy conversion device of steam cabinet

An energy conversion device and hot steam technology, applied in steam cooking utensils, cooking utensils, household appliances, etc., can solve the problems of difficult and convenient loading and quick maintenance, poor overall energy saving effect, and complex overall structure, etc., to achieve compact structure, increase Occupies a lot of space and has good safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

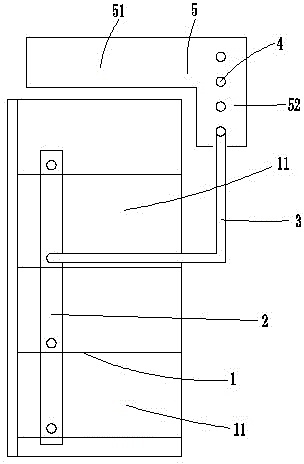

[0016] Embodiment 1 of the present invention, a hot steam energy conversion device for a steaming cabinet, including a steaming cabinet body 1 and a water energy storage tank 5, the steaming cabinet body 1 has a built-in unit steaming cabinet 11, and the outer wall of the steaming cabinet body 1 is equipped with The steam collection channel 2, and the entrance of the steam collection channel 2 is respectively connected with the steam outlet of the steam cabinet 11 of the unit, and the outlet of the steam collection channel 2 is equipped with a delivery pipe 3; 3 outlet connections.

[0017] The water energy storage box 5 is arranged on the top surface of the steamer body 1; and the water energy storage box 5 is equipped with a water inlet valve and a water discharge valve. The side of the water energy storage box 5 is equipped with a water temperature detector.

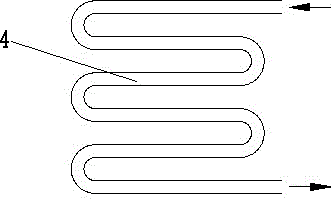

[0018] The heat dissipation pipe 4 is wound in an S shape, and its outlet is located below and discharged outward....

Embodiment 2

[0019] Embodiment 2 of the present invention, a hot steam energy conversion device for a steaming cabinet, includes a steaming cabinet body 1 and a water energy storage tank 5, the steaming cabinet body 1 has a built-in unit steaming cabinet 11, and the outer wall of the steaming cabinet body 1 is equipped with The steam collection channel 2, and the entrance of the steam collection channel 2 is respectively connected with the steam outlet of the steam cabinet 11 of the unit, and the outlet of the steam collection channel 2 is equipped with a delivery pipe 3; 3 outlet connections.

[0020] The water energy storage box 5 is arranged on the top surface of the steamer body 1; and the water energy storage box 5 is equipped with a water inlet valve and a water discharge valve. The side of the water energy storage box 5 is equipped with a water temperature detector.

[0021] The heat dissipation pipe 4 is wound in an S shape, and its outlet is located below and discharged outward. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com