Performance Evaluation Method of Condensing Steam Turbine After High Back Pressure Retrofit

An evaluation method and high back pressure technology, applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve the problem of inability to evaluate the technical performance of high back pressure transformation of condensing steam turbines, reduce unit power generation, test Problems such as the inability of the results to be compared with the design values under the design conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the drawings and embodiments.

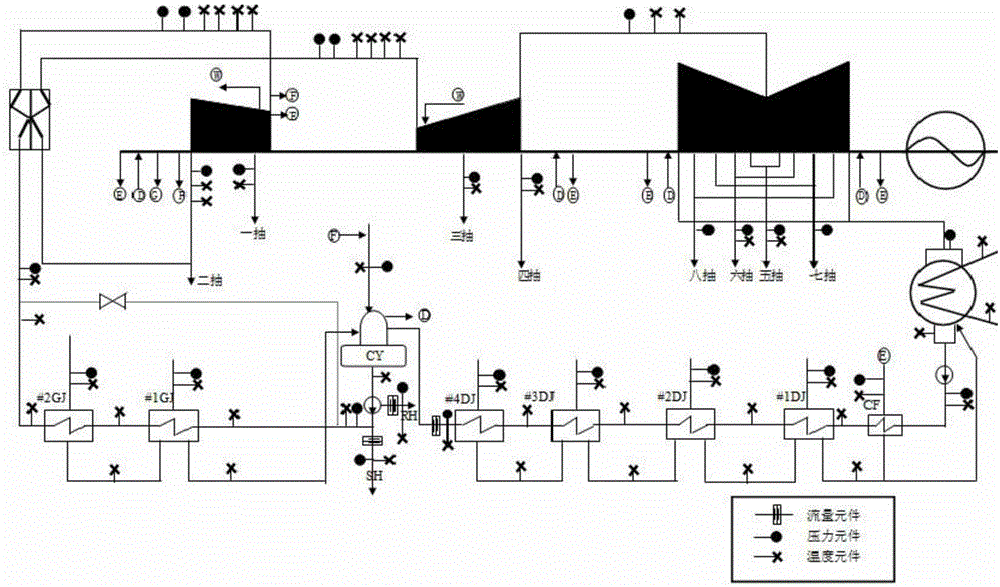

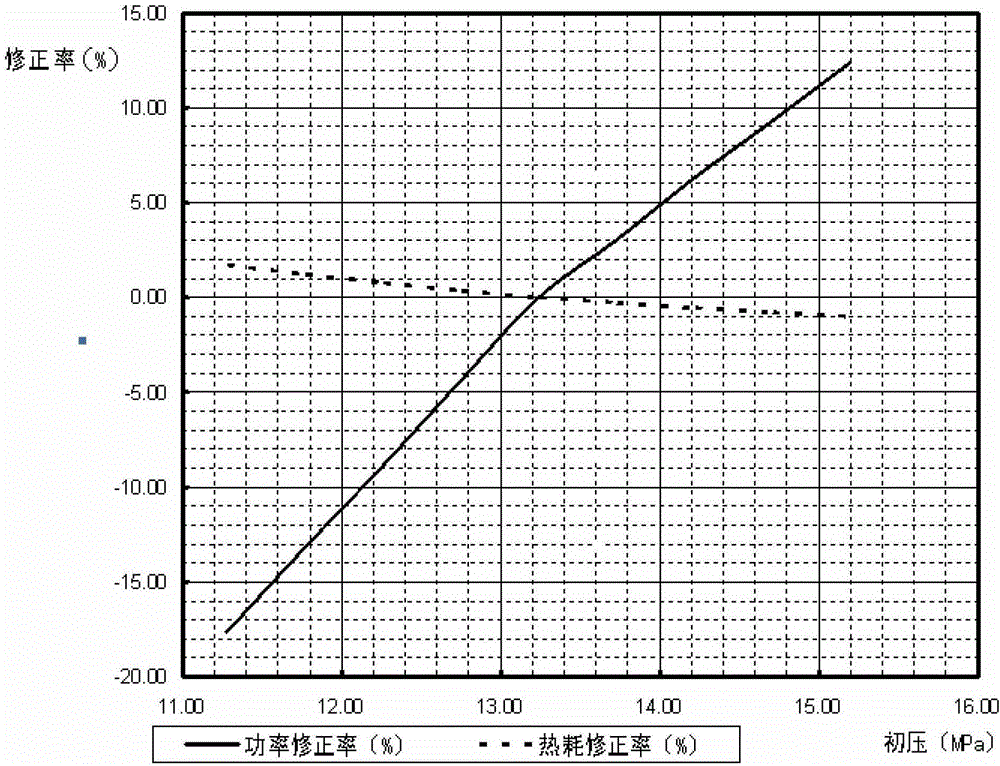

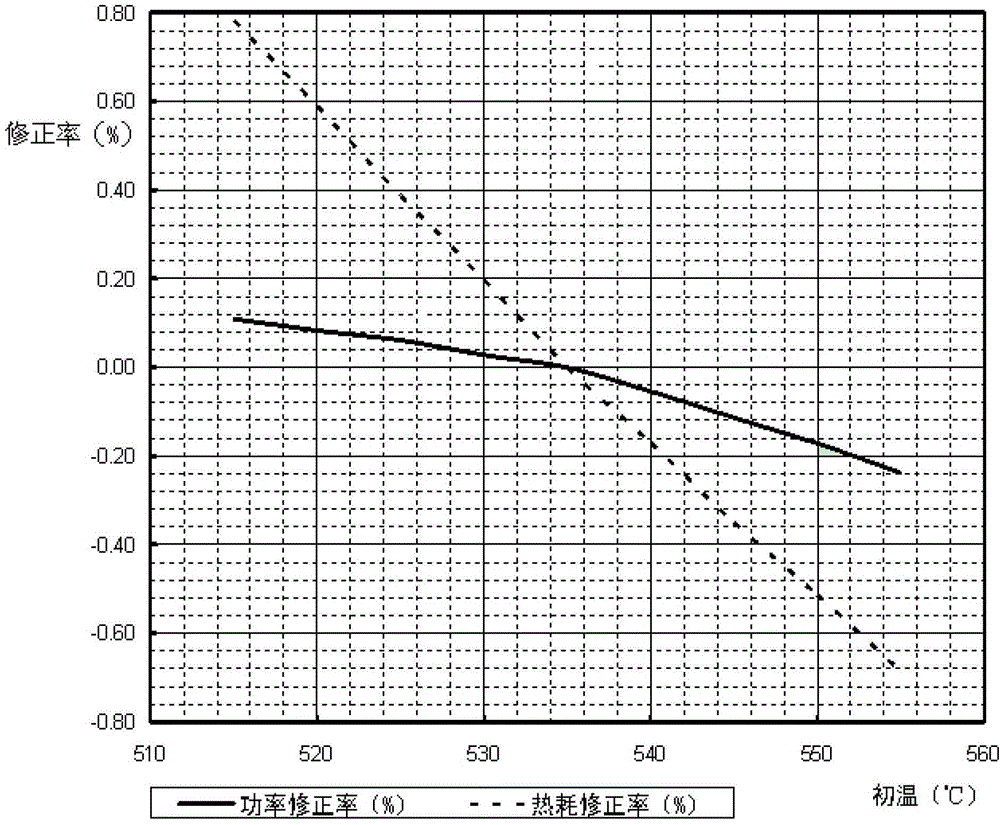

[0060] A 140MW steam turbine was originally an ultra-high pressure unit produced by Shanghai Steam Turbine Co., Ltd. In order to realize the high back pressure heating of the unit, the flow passage part of the low pressure cylinder has been modified. In the heating season, the low pressure cylinder adopts a high back pressure rotor with the last two stage baffles and moving blades removed. Type of unit after transformation: ultra-high pressure, primary reheating, double cylinder, double exhaust, single extraction, condensing steam turbine; model: N112 / C112-13.24 / 0.24 / 535 / 535; high back pressure operation condensing Steam turbine exhaust pressure (extraction / condensation): 43.6kPa; heat consumption rate (extraction / condensation) of the unit with high back pressure operation: 3684.8 / 3776.6kJ / kW.h.

[0061] Perform steam turbine unit performance test in accordance with GB / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com