Method for producing textile coated with coating adhesive

A technology for coating glue and textiles, applied in textiles and papermaking, fiber processing, physical processing, etc., can solve the problems of high energy consumption, expensive platinum catalyst, added price, etc., and achieve low energy consumption, low raw material cost, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

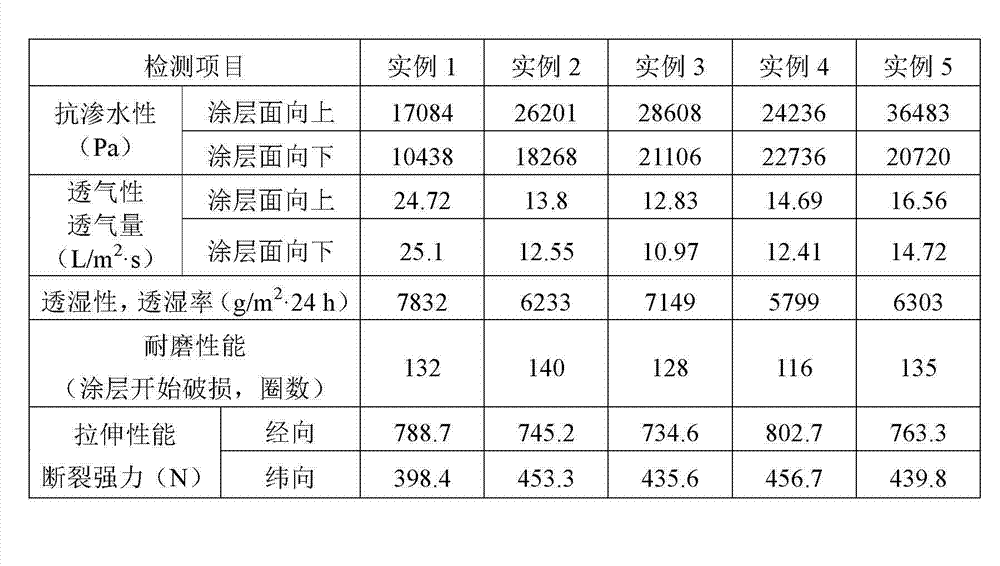

Embodiment 1

[0038] 1) To prepare the coating glue, take 70% double-capped vinyl silicone oil (molecular weight 30,000, vinyl content 6%), 10% hydrogen-containing silicone oil, 10% oily polyurethane resin, 1% silane coupling agent, and pentaerythritol triacrylate 5%, nano-scale white carbon black 4%, high-efficiency shearing and mixing at room temperature to obtain a coating glue with a viscosity in the range of 30000 cp;

[0039] 2) The base fabric is hot-pressed by the hot-pressing roller of the calender;

[0040]3) Apply the coating glue prepared in step 1) on the calendered base fabric, the speed of the front and rear driving rollers of the coating machine is 5 m / min, adjust the angle of the coating knife to 110o, and the coating amount of the coating glue is 30 g / m 2 ;

[0041] 4) Put the base fabric coated with coating glue in step 3) through the front and rear transmission rollers of the coating machine and place it on the transmission beam frame of the 200 KeV low-energy electro...

Embodiment 2

[0044] 1) To prepare the coating glue, take 55% double-capped vinyl silicone oil (molecular weight 30000, vinyl content 6%), 15% hydrogen-containing silicone oil, 15% oily polyurethane resin, 2% silane coupling agent, and pentaerythritol triacrylate 10%, 5% of nano-scale white carbon black, high-efficiency shear mixing at room temperature, to obtain a coating glue with a viscosity in the range of 40000 cp;

[0045] 2) The base fabric is hot-pressed by the hot-pressing roller of the calender;

[0046] 3) Apply the coating glue prepared in step 1) on the calendered base fabric, the speed of the front and rear drive rollers of the coating machine is 10 m / min, adjust the angle of the coating knife to 110o, and the coating amount of the coating glue is 10 g / m 2 ;

[0047] 4) Put the base fabric coated with coating glue in step 3) through the front and rear transmission rollers of the coating machine and place it on the transmission beam frame of the 200 KeV low-energy electron a...

Embodiment 3

[0050] 1) To prepare the coating glue, take 55% of double-capped vinyl silicone oil (molecular weight: 10,000, vinyl content: 8%), 14% hydrogen-containing silicone oil, 14% oily polyurethane resin, 2% silane coupling agent, and pentaerythritol triacrylate 10%, 5% of nano-scale white carbon black, high-efficiency shear mixing at room temperature, to prepare a coating glue with a viscosity in the range of 35000 cp;

[0051] 2) The base fabric is hot-pressed by the hot-pressing roller of the calender;

[0052] 3) Apply the coating glue prepared in step 1) on the calendered base fabric, the speed of the front and rear drive rollers of the coating machine is 5 m / min, adjust the angle of the coating knife to 120o, and the coating amount of the coating glue is 20 g / m 2 ;

[0053] 4) Put the base fabric coated with coating glue in step 3) through the front and rear transmission rollers of the coating machine and place it on the transmission beam frame of the 200 KeV low-energy elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com