Brown coal modification and upgrading method

A modified lignite technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of difficult to realize large-scale lignite drying production, immature lignite upgrading, complex equipment and technology, etc., and can be easily promoted in large areas , no explosion hazard, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

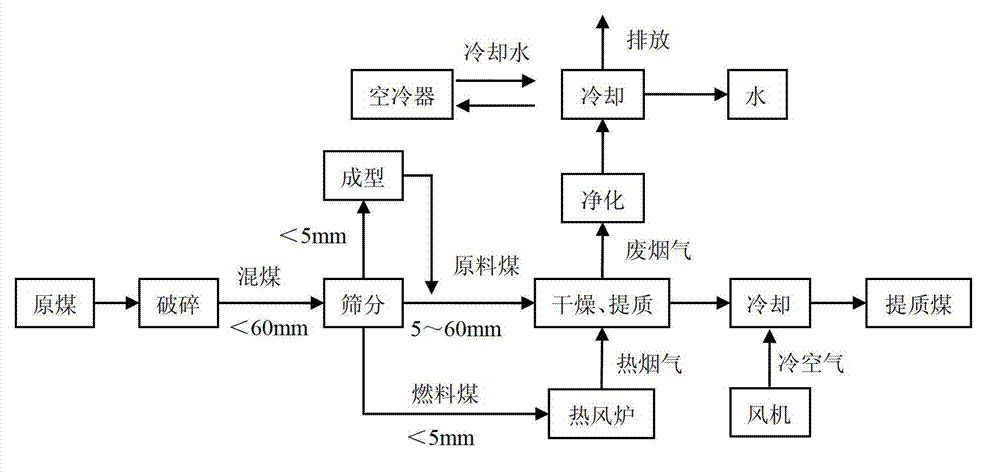

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] With reference to accompanying drawing, a kind of lignite modification and upgrading method comprises the following steps:

[0021] In the first step, the raw coal from the coal mine is crushed into granular coal of <60mm, which is screened and classified into two particle sizes of <5mm and 5-60mm;

[0022] In the second step, part of the pulverized coal <5mm is used as coal for hot blast stove combustion, and the rest is pressed into briquettes by extrusion molding technology;

[0023] In the third step, the extruded briquettes are mixed with 5-60mm granular coal into the drying section of the furnace, heated by the inert flue gas from the hot blast stove <300°C, and the coal is heated to 180°C-200°C under the condition of isolation of air. ℃, remove more than 90% of the total water and crystallization water that affect the calorific value of coal, and complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com