Novel waste paper papermaking waste water comprehensive treatment method and system

A comprehensive treatment, waste paper papermaking technology, applied in the direction of water/sewage multi-stage treatment, flotation water/sewage treatment, light water/sewage treatment, etc., can solve the problem of increased soluble COD, increased difficulty in papermaking wastewater treatment, Inability to adapt to processing requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

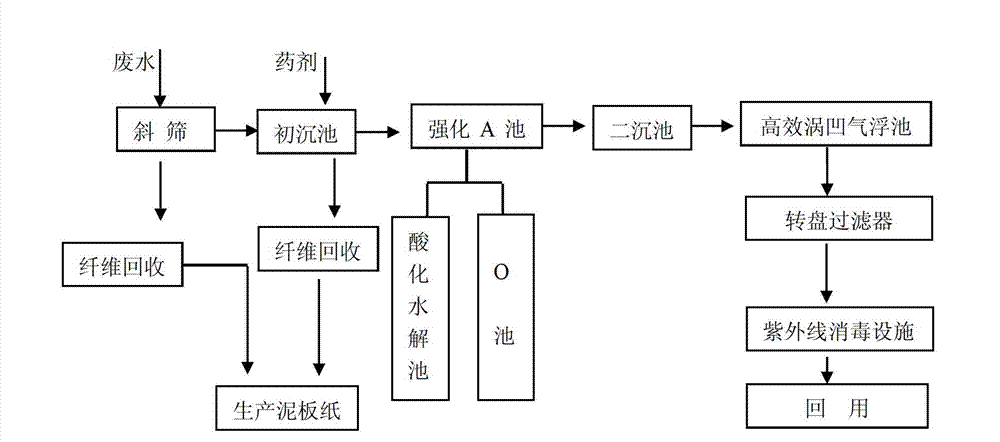

[0031] Such as figure 1 As shown, the papermaking wastewater treatment system of the present invention includes inclined screen, primary sedimentation tank, strengthening A pond, secondary sedimentation tank, high-efficiency vortex concave air flotation tank, rotary disc filter and ultraviolet disinfection facility; inclined screen, primary sedimentation tank, Strengthened A pool, secondary sedimentation tank, high-efficiency vortex concave air flotation tank, rotary disc filter and ultraviolet disinfection facilities are connected through pipelines in sequence. The strengthened A pool includes an acidified hydrolysis pool and an O pool, and the acidified hydrolysis pool and the O pool are connected in sequence.

[0032] The wastewater from the waste paper papermaking workshop enters the primary sedimentation tank after passing through the inclined screen, and most of the long fibers are recovered by the inclined screen, and are directly sent to the fiber recycling place for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com