Preparation method of compound bismuth aluminate tablet

A technology of compound bismuth aluminate tablet and bismuth aluminate, which is applied in the directions of medical preparations containing active ingredients, pharmaceutical formulations, active ingredients of aluminum/calcium/magnesium, etc. The daily production capacity cannot be met and other problems, so as to achieve the effect of solving poor safety, reducing fluctuations in the content of finished products, and avoiding hidden dangers in safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

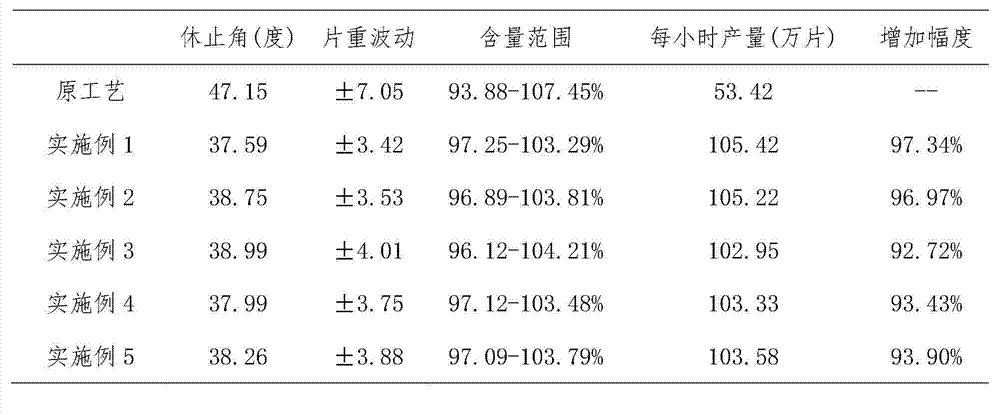

Examples

Embodiment 1

[0022] A preparation method of compound bismuth aluminate sheet, comprising the following steps:

[0023] (1) Take bismuth aluminate and pass through a 120-mesh sieve, and set aside; take heavy magnesium carbonate, sodium bicarbonate, licorice extract powder, frangipani bark powder, and fennel powder, pass through a 100-mesh sieve, and set aside; take filling and diluting Agents, disintegrants and lubricants passed through a 100-mesh sieve for later use.

[0024] (2) Weigh 200g of bismuth aluminate, 400g of heavy magnesium carbonate, 200g of sodium bicarbonate, 300g of licorice extract powder, 25g of buckthorn bark powder, 20g of dextrin, and 50g of starch and mix them uniformly to obtain mixture A.

[0025] (3) Spray 45g of purified water into the mixture A in an atomized state and in a fan shape of 65 degrees, wet granulate, granulate through 16 mesh, dry the granules to a water content of 1%-7%, and granulate through 14 mesh to obtain Particle A.

[0026] (4) Mix granule ...

Embodiment 2

[0030] A preparation method of compound bismuth aluminate sheet, comprising the following steps:

[0031] (1) Take bismuth aluminate and pass through a 120-mesh sieve, and set aside; take heavy magnesium carbonate, sodium bicarbonate, licorice extract powder, frangipani bark powder, and fennel powder, pass through a 100-mesh sieve, and set aside; take filling and diluting Agents, disintegrants and lubricants passed through a 100-mesh sieve for later use.

[0032] (2) Weigh 200g bismuth aluminate, 420g heavy magnesium carbonate, 280g sodium bicarbonate, 300g licorice extract powder, 28g buckthorn bark powder, 30g dextrin, 80g lactose, 85g starch and mix evenly to obtain a mixture a.

[0033] (3) Spray 52g of purified water into the mixture A in an atomized state in a solid conical shape of 61 degrees and a fan shape of 73 degrees, and wet granulate, pass through 16 mesh for granulation, and dry the granules to a water content of 1%-7%. Granule A was obtained through 14-mesh s...

Embodiment 3

[0038] A preparation method of compound bismuth aluminate sheet, comprising the following steps:

[0039] (1) Take bismuth aluminate and pass through a 120-mesh sieve, and set aside; take heavy magnesium carbonate, sodium bicarbonate, licorice extract powder, frangipani bark powder, and fennel powder, pass through a 100-mesh sieve, and set aside; take filling and diluting Agents, disintegrants and lubricants passed through a 100-mesh sieve for later use.

[0040] (2) Weigh 150g of bismuth aluminate, 370g of heavy magnesium carbonate, 180g of sodium bicarbonate, 150g of licorice extract powder, 35g of buckthorn bark powder, 430g of lactose, and 40g of crospovidone and mix them evenly to obtain a mixture a.

[0041] (3) Spray 100g of purified water into the mixture A in an atomized state and in the form of a 60-degree hollow cone, wet granulate, pass through 20 mesh for granulation, dry the granules to a water content of 1%-7%, pass through 18 mesh for granulation Granule A wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com