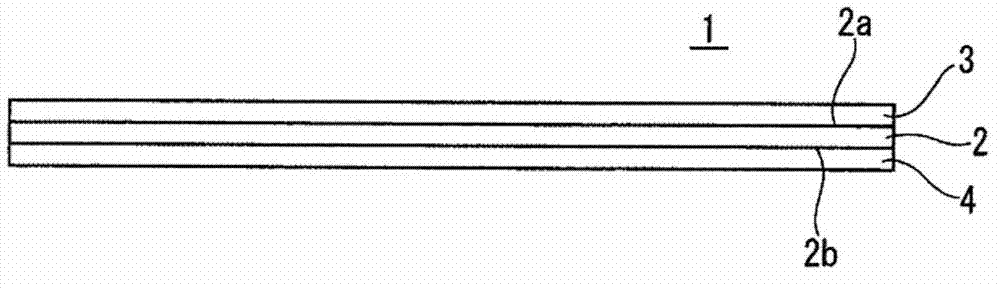

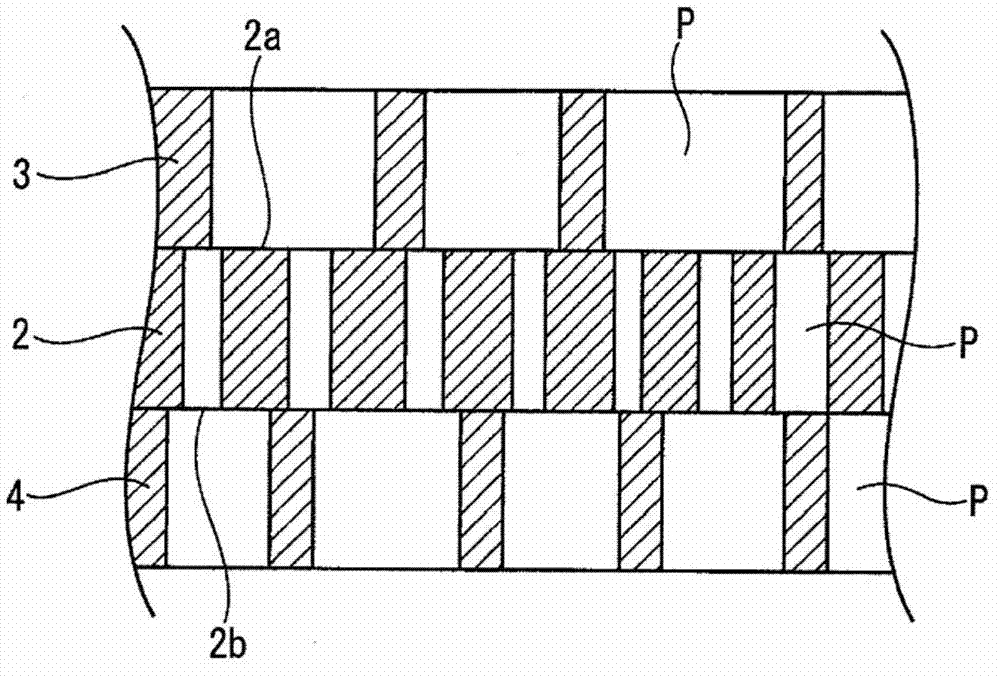

Porous multilayered filter

A filter and filter layer technology, which is applied in the direction of layered products, chemical instruments and methods, and synthetic resin layered products, can solve the problems of reduced particle collection ability, achieve increased strength, reduced thickness, and prevent filtration performance Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0126] 18 parts by mass of a liquid lubricant (Supersol FP-25 (ingredient: naphtha) manufactured by Idemitsu Kosan Co., Ltd.) was added to 100 parts by mass of PTFE fine powder (PTFE601A manufactured by DuPont Corporation) and mixed. In a molding machine, the resulting mixture is subjected to compression molding to form a block shaped body.

[0127] Next, the block shaped body is continuously extruded into a sheet shape. This sheet-shaped molded body is passed through a press roll, further passed through a heated roll (130°C to 220°C) to remove the liquid lubricant, and wound up on a roll to obtain a 300 μm sheet, which will be used Sheet material that acts to form a filter layer. In addition, a 250 μm sheet was obtained as a sheet for forming a support layer and a protective layer.

[0128] Next, the sheet for forming the filter layer is stretched in the machine direction (machine direction) at a rate of 2 times at a roll temperature of 250°C to 280°C, and then stretched at...

Embodiment 2)

[0134] In order to set the average pore size of the filter layer 2 to 0.05 μm, the stretch ratios of the sheets forming the filter layer in the longitudinal and transverse directions are set like this: as shown in Table 1, the first longitudinal stretch ratio is 2 times, and the first longitudinal stretch ratio is 2 times. Two, the longitudinal stretching ratio is 3 times, and the transverse stretching ratio is 21.5 times. Then, the same procedure as in Example 1 was performed.

Embodiment 3)

[0136] In order to set the average pore size of the filter layer 2 to 0.10 μm, the stretch ratios of the sheet forming the filter layer in the longitudinal and transverse directions are set like this: as shown in Table 1, the first longitudinal stretch ratio is 2 times, and the first longitudinal stretch ratio is 2 times. Two, the longitudinal stretching ratio is 3 times, and the transverse stretching ratio is 21.5 times. Then, the same procedure as in Example 1 was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com