Method for optimizing photoetching registration accuracy of emitting electrode of silicon germanium HBT (heterojunction bipolar transistor)

An alignment accuracy and emitter technology, applied in the field of photolithography, can solve the problems of poor stability, unstable mass production, and difficulty in improving photolithography alignment accuracy, so as to enhance optical contrast and avoid optical alignment accuracy. Measurement Error and Effects of Instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

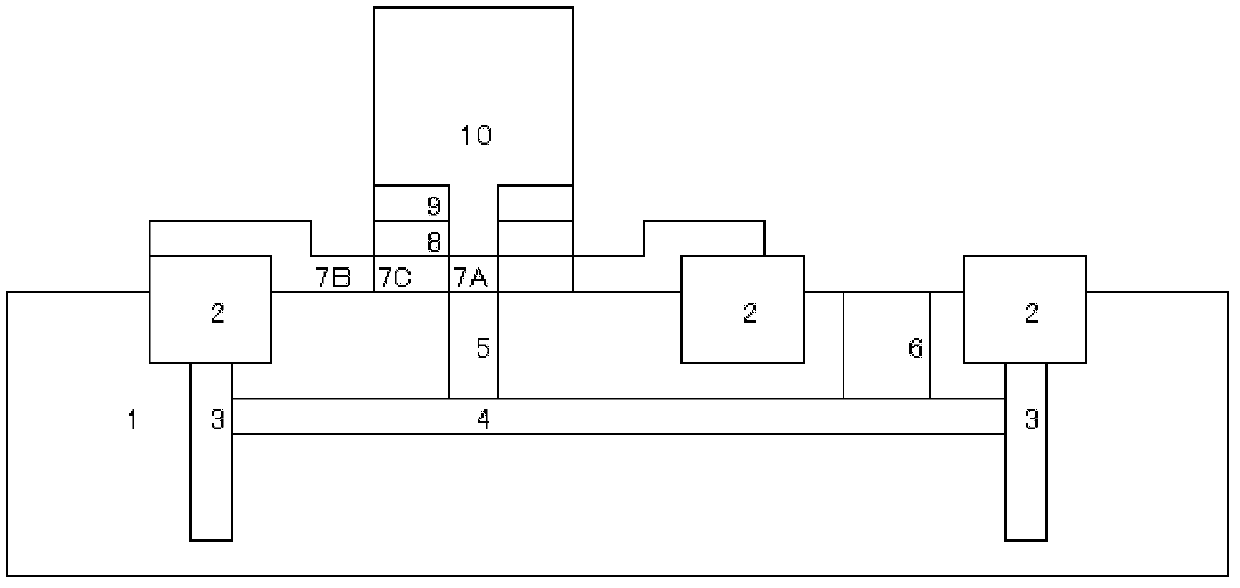

[0034] The method for optimizing the photolithographic alignment accuracy of the silicon germanium HBT emitter according to the present invention, the preparation process of the photolithographic alignment mark and the OVLmark is as follows:

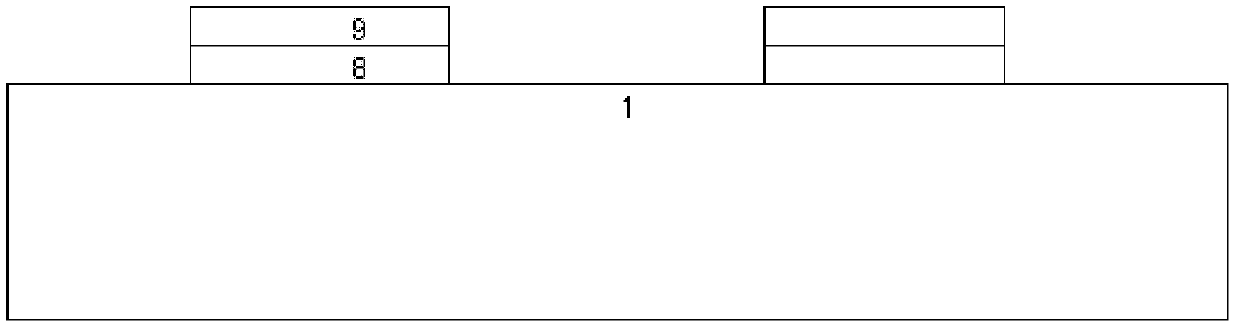

[0035] 1. Photolithography etches the silicon substrate to produce grooves with a depth of preferably

[0036] 2. Fill the trench with SiO 2 and planarize to remove the SiO in the non-trench area 2 ;

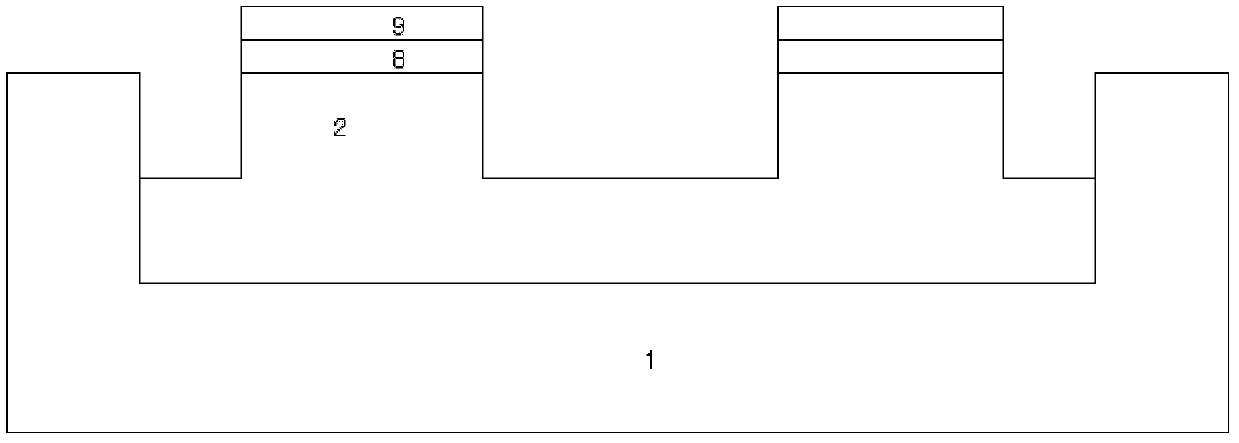

[0037] 3. Deposit the buffer layer SC between BP and the substrate (SiO2+SiN or SiO2+Poly, the thickness is SiO2 Upper material ), etch the SC layer, open the device area, and produce two groups of patterns of etching and non-etching in the photolithographic pattern area.

[0038] 4. Deposit BP film (Si / Ge) and etch it, and dry etch the barrier layer SiO 2 , until SiO 2 stop, residual SiO 2 for

[0039] 5. Deposit the emitter opening film on the silicon substrate (active area), and the lower layer is SiO 2 , usually pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com