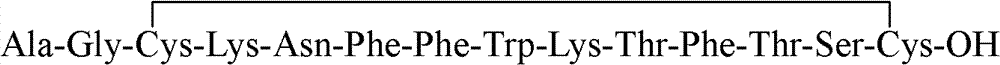

Method for preparing somatostatin through solid-phase peptide synthesis

A technology for solid-phase peptide synthesis and somatostatin, which is applied to peptide preparation methods, chemical instruments and methods, peptides, etc., can solve the troublesome operation of pentapeptides, limit the large-scale production and use of somatostatin, and troublesome operation of dipeptides And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

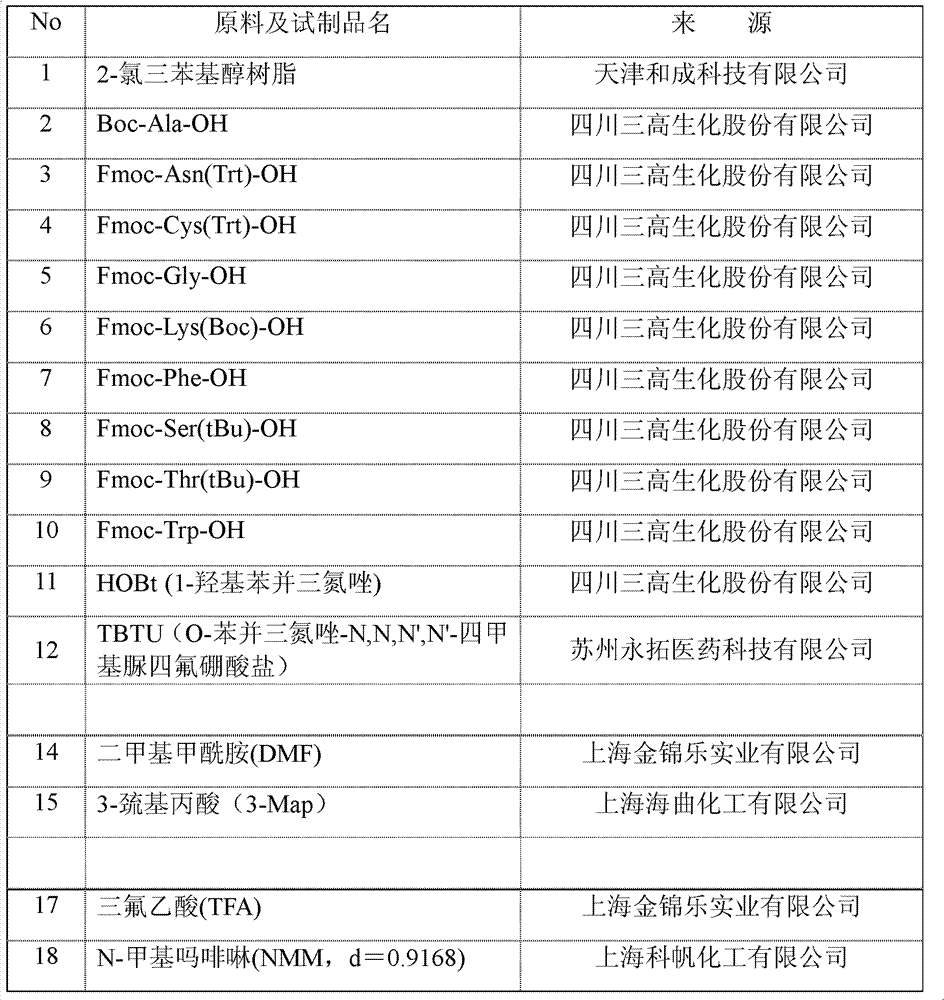

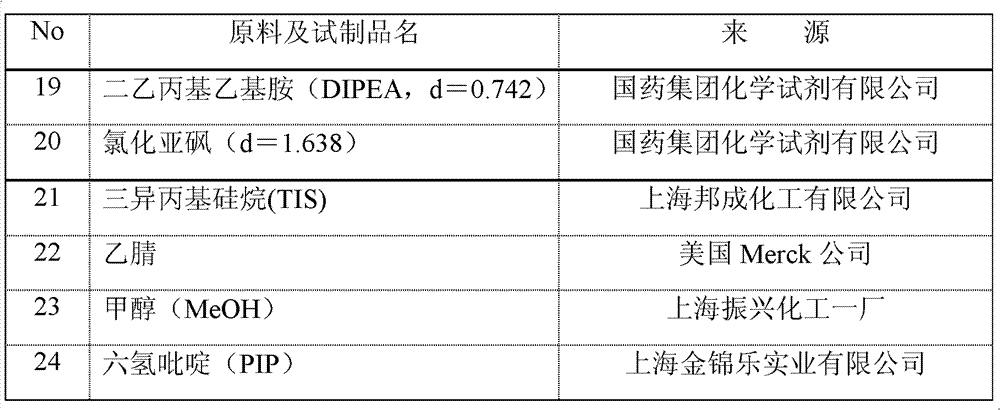

[0084] The list of raw materials adopted in the embodiment and the foregoing process is as follows:

[0085]

[0086]

[0087] Example 1

[0088] (1) Production of Fmoc-Cys(Trt)-resin

[0089] Weigh 2.22kg of 2-chlorotriphenyl alcohol resin (100-150 mesh, 0.7mmol / g), put it into a 50L polypeptide synthesizer, add 14LDCM, stir and swell at room temperature for 1 hour. Under stirring, 3.6 kg of thionyl chloride (d=1.638) was slowly added dropwise through a constant pressure funnel within 30 minutes, and then stirred and reacted at room temperature for 3 hours.

[0090] Drain, wash with 72LDCM 6 times, each time with 12LDCM, stir for 15 minutes and then drain.

[0091] Add 7L of DMF, then add 1.76kg of Fmoc-Cys(Trt)-OH dissolved in 7L of DMF, and 1.187kg of DIPEA, and react at 35±3°C for 1.5 hours. Add 2.5 L of methanol and react at 34.5±2.5°C for 30 minutes. Drained, the resin was washed once with methanol, washed five times with DMF, and dried.

[0092] (2) Productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com