Tempered, semi-tempered low-altitude glass and manufacturing method thereof

A low-altitude glass and semi-tempered technology, which is applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve the problems affecting the normal service life of insulating glass, affecting the service life of insulating glass, and failure of insulating glass, so as to promote industrial production, Less pressure and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention provides the above-mentioned preparation method of tempered and semi-tempered low-altitude glass. When the material of the support is low-temperature glass powder, it includes:

[0063] The first step is to cut two pieces of flat glass of the required size according to the shape and size of the low-altitude glass to be produced, and carry out edge grinding, chamfering, cleaning and drying;

[0064] The second step is to use stencil printing technology and low-temperature glass powder on the welding surface of the treated glass to prepare the edge-sealing frame and support, and ensure that after the upper and lower glass are aligned, the edge-sealing frame of the upper glass can be embedded in the Between the edge-sealing bars and frames of the lower glass, and then after drying, it is tempered in a tempering furnace;

[0065] In the third step, the support on the glass obtained in the second step is machined so that its top end is located in the se...

Embodiment 1

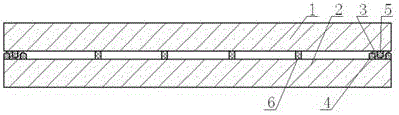

[0078] Example 1: see figure 1 , the two pieces of low-altitude glass are tempered glass or semi-tempered glass, one of which is low-emissivity glass, and there are edge-sealing frames on both pieces of glass. The production method is as follows: First, cut according to the shape and size of the low-altitude glass. A piece of flat glass and a piece of low-emissivity glass of the required size are edged, chamfered, cleaned and dried, and then the low-temperature glass powder paste is printed on the two pieces of glass to form an edge-sealing frame by printing technology. One edge-sealing frame and the lower glass have two edge-sealing frames. The size of the upper-glass edge-sealing frame is between the two edge-sealing frames of the lower glass. After the upper and lower glass are combined, the upper-glass edge-sealing frame It can be fitted between the two edge-sealing frames of the lower glass, and the width of each edge-sealing frame is 1.5mm and the height is 0.6mm; second...

Embodiment 2

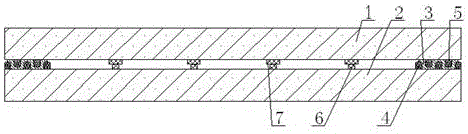

[0081] Example 2: see figure 2 , the two pieces of low-altitude glass are tempered glass or semi-tempered glass, one of which is low-emissivity glass, and there are edge-sealing frames on both pieces of glass. The production method is as follows: First, cut according to the shape and size of the low-altitude glass. A piece of flat glass and a piece of low-emissivity glass of the required size are edged, chamfered, cleaned and dried, and then the low-temperature glass powder paste is printed on the two pieces of glass to form an edge-sealing frame by printing technology. There are two edge-sealing frames and the lower glass has three edge-sealing frames. The size of the upper glass edge-sealing frame is between the lower glass edge-sealing frames. It fits between the edge bands of the lower glass. The width of each edge band is 1.5mm and the height is 0.7mm; and supports are printed on the upper and lower glass at the same time. The smallest unit of the supports is equilateral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com