One-step synthetic preparation method of CuInS2 nanowires

A technology of mixture and thiocarbamic acid, which is applied in the direction of nanotechnology, chemical instruments and methods, gallium/indium/thallium compounds, etc., can solve the problems of cumbersome preparation process, high vacuum degree requirements, expensive equipment, etc., and overcome the reaction conditions complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

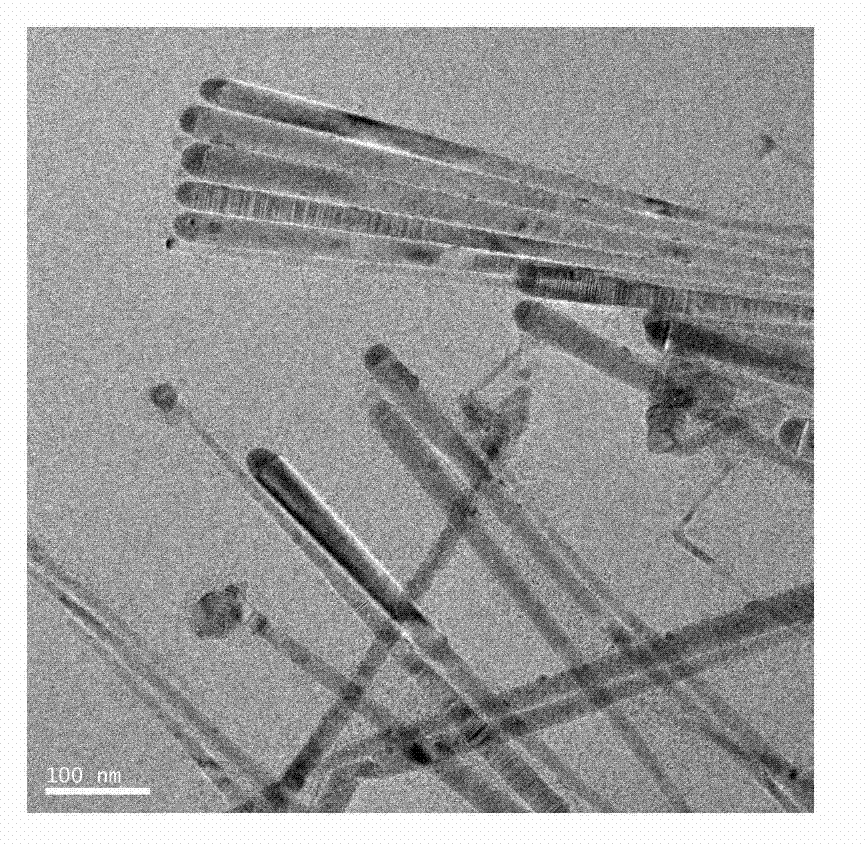

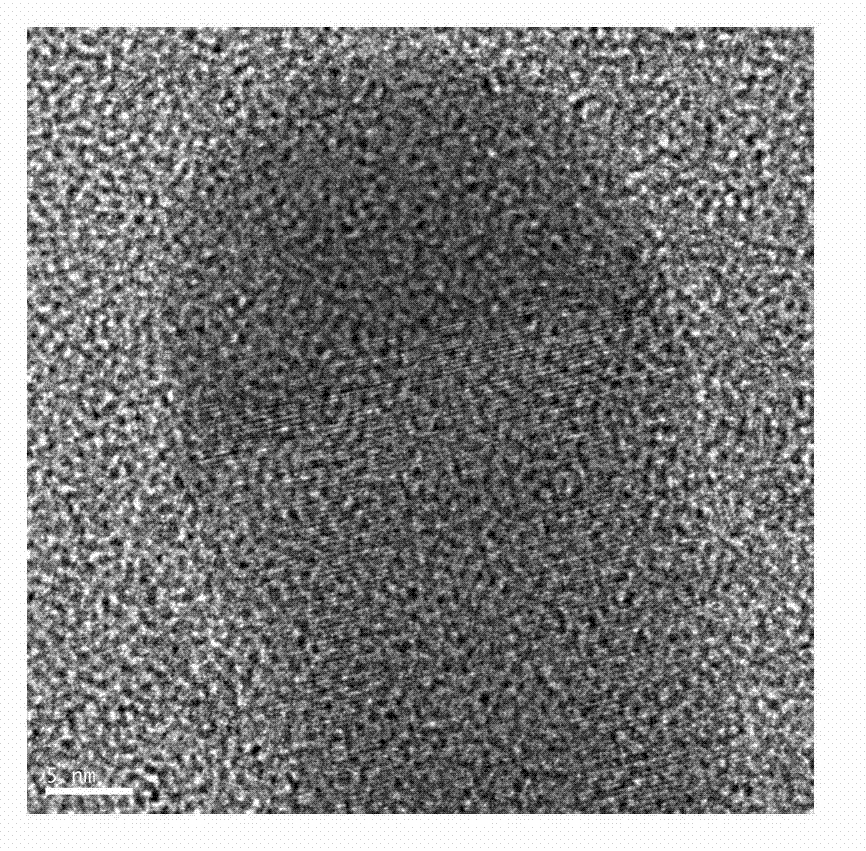

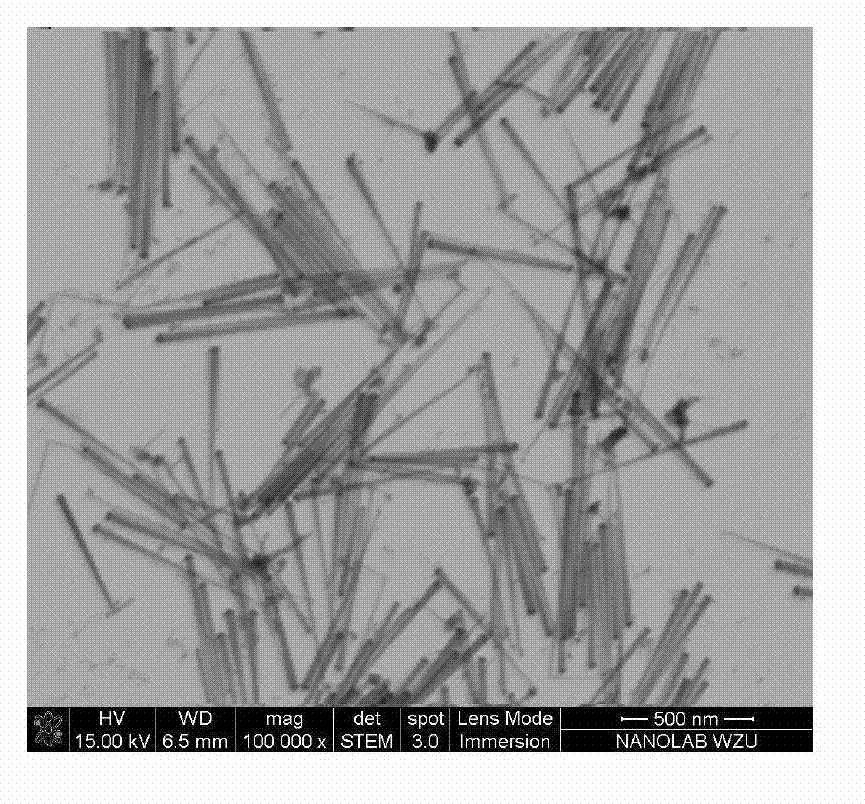

Image

Examples

Embodiment 1

[0024] Add 0.005mmol silver diethyldithiocarbamate, 0.05mmol copper acetylacetonate, and 0.05mmol dibutyldithiocarbamate indium to a 100mL round-bottomed flask, followed by adding 1.5mmol oleylamine, 15mmol dodeca Mercaptan, 12mmol n-trioctylphosphine oxide, the flask was placed in an oil bath with a constant temperature of 200°C, and the reaction was stirred by magnetic force for 60min. After the reaction was completed, it was cooled to room temperature, the original solution was taken out, diluted with n-hexane, ultrasonically oscillated for 60min, and centrifuged at 10000rpm Separation 10min, CuInS 2 The knot settles at the bottom of the container, and the supernatant is discarded to obtain CuInS 2 Nanowires. The molar concentration ratio of the above-mentioned silver thiocarbamate, copper acetylacetonate, and indium thiocarbamate is 1:10:10, and the molar concentration ratio of indium thiocarbamate and amines is 1:30. The amines, sulfur The molar concentration ratio of a...

Embodiment 2

[0026] Add 0.005mmol silver diisopropyldithiocarbamate, 0.05mmol copper acetylacetonate and 0.05mmol indium diethyldithiocarbamate to a 100mL round-bottomed flask, followed by adding 25mmol dodecylamine, 250mmol decathene Put octamercaptan, 250mmol oleic acid, put the flask in an oil bath with a constant temperature of 260°C, stir the reaction for 60min with magnetic force, cool to room temperature after the reaction, take out the original solution, dilute with n-hexane, oscillate ultrasonically for 10min, and centrifuge at 10000rpm for 10min , CuInS 2 The knot settles at the bottom of the container, and the supernatant is discarded to obtain CuInS 2 Nanowires. The molar concentration ratio of the above-mentioned silver thiocarbamate, copper acetylacetonate, and indium thiocarbamate is 1:100:100, and the molar concentration ratio of indium thiocarbamate and amines is 1:500. The amines, sulfur The molar concentration ratio of alcohol and surface ligand is 1:10:10.

Embodiment 3

[0028] Add the reaction precursor 0.005mmol silver diethyldithiocarbamate, 0.5mmol copper acetylacetonate, 0.5mmol indium diisopropyldithiocarbamate into a 100mL round bottom flask, and then add 15mmol octylamine, 15mmol hexylsulfur Alcohol, 15mmol 3-mercaptopropionic acid, the flask was placed in an oil bath with a constant temperature of 200°C, and the reaction was stirred by magnetic force for 60 minutes. After the reaction was completed, it was cooled to room temperature, and the original solution was taken out, diluted with n-hexane, ultrasonically oscillated for 10 minutes, and centrifuged at 10,000rpm 10min, CuInS 2 The knot settles at the bottom of the container, and the supernatant is discarded to obtain CuInS 2 Nanowires. The molar concentration ratio of the above-mentioned silver thiocarbamate, copper acetylacetonate, and indium thiocarbamate is 1:100:100, and the molar concentration ratio of indium thiocarbamate and amines is 1:30. The amines, sulfur The molar co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com