Nitrogen-doped chitosan-based activated carbon and preparation method thereof

A technology of activated carbon preparation and chitosan, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as environmental pollution, increased production costs, waste of water resources, etc., to avoid environmental unfriendly, pore size distribution The effect of concentrating and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

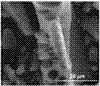

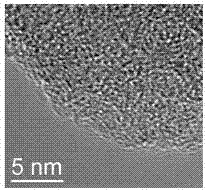

[0025] 1. Add 2 g of chitosan to 70 mL of deionized water, stir for 5 minutes, then add 10 mL of hydrochloric acid with a concentration of 1 mol / L, and stir for 2 hours to obtain a chitosan solution. Freeze the chitosan solution at minus 15 °C for 2 h. The frozen solid is put into a freeze dryer for drying to obtain chitosan xerogel. The chitosan xerogel obtained was placed in a carbonization furnace, and was raised from room temperature to 800 °C at a heating rate of 5 °C / min under a nitrogen atmosphere, kept at a constant temperature for 1 hour, and then naturally cooled to room temperature. The obtained carbonized product was ground into powder, sieved through a 300-mesh sieve, then boiled with deionized water for 90 minutes, filtered with suction, and the filter cake was dried in a vacuum oven at 100°C for 12 hours to obtain a nitrogen-doped activated carbon material. Elemental analysis determined that the nitrogen content of the material was 5.98 wt%.

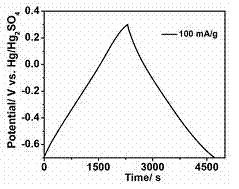

[0026] 2. Take t...

Embodiment 2

[0029] 1. Add 2 g of chitosan to 70 mL of deionized water, stir for 15 minutes, then add 200 mL of hydrochloric acid with a concentration of 0.05 mol / L, and stir for 12 hours to obtain a chitosan solution. Freeze the chitosan solution at minus 30 °C for 1 h. The frozen solid is put into a freeze dryer for drying to obtain chitosan xerogel. The obtained chitosan xerogel was placed in a carbonization furnace, and the heating rate was raised from room temperature to 700 °C at a heating rate of 1 °C / min under an argon atmosphere, kept at a constant temperature for 1 hour, and then naturally cooled to room temperature. The obtained carbonized product was ground into powder, sieved through a 300-mesh sieve, then boiled with deionized water for 120 minutes, filtered with suction, and the filter cake was dried in a vacuum oven at 100°C for 12 hours to obtain a nitrogen-doped activated carbon material. Elemental analysis determined that the nitrogen content of the material was 7.82 wt...

Embodiment 3

[0033] 1. Add 2 g of chitosan to 140 mL of deionized water, stir for 30 minutes, then add 4 mL of hydrochloric acid with a concentration of 3 mol / L, and stir for 24 hours to obtain a chitosan solution. Freeze the chitosan solution at minus 35°C for 12 hours. The frozen solid is put into a freeze dryer for drying to obtain chitosan xerogel. The chitosan xerogel obtained was placed in a carbonization furnace, and was raised from room temperature to 900 °C at a heating rate of 10 °C / min under a nitrogen atmosphere, kept at a constant temperature for 1 hour, and then naturally cooled to room temperature. The obtained carbonized product was ground into powder, sieved through a 300-mesh sieve, then boiled with deionized water for 180 minutes, filtered with suction, and the filter cake was dried in a vacuum oven at 100°C for 12 hours to obtain a nitrogen-doped activated carbon material. Elemental analysis determined that the nitrogen content of the material was 3.20 wt%.

[0034] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com