Enramycin dry suspension and preparation method thereof

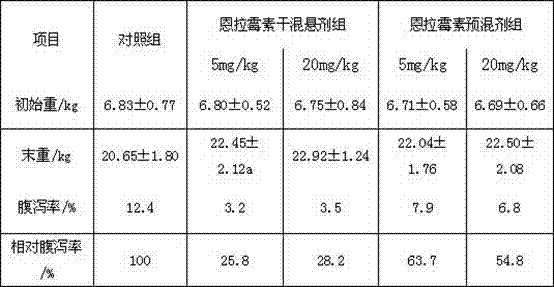

A technology of enramycin and dry suspension, applied in the field of enramycin dry suspension and preparation thereof, can solve problems such as uneven mixing, poisoning, unsatisfactory drug effect, etc. Convenient, fast-acting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Enramycin 2g

[0038] Sucrose 60g

[0040] Methylcellulose 25g

[0041] Glycerin 3g

[0042] The preparation method is as follows:

[0043] (1) Accurately weigh the enramycin of the prescribed amount and pass through an 80-mesh sieve;

[0044] (2) Accurately weigh the sucrose, sodium saccharin, and methylcellulose of the prescribed amount respectively, pass through an 80-mesh sieve respectively, and mix uniformly in equal increments;

[0045] (3) Steps (1) and (2) are mixed in equal increments to obtain a mixed powder;

[0046] (4) Add 3g of glycerin to the mixed powder to make a soft material, and pass through a 40-mesh sieve;

[0047] (5) Dry at 60°C, granulate with 40 mesh sieve;

[0048] (6) After the intermediate is qualified, the finished product can be obtained by sub-packaging.

Embodiment 2

[0050] Enramycin 8g

[0051] Mannose 20g

[0052] Cyclamate 40g

[0053] Hydroxypropyl Methyl Cellulose 30g

[0054] 50% ethanol 2g

[0055] The preparation method is as follows:

[0056] (1) Accurately weigh the enramycin of prescription quantity and pass through 120 mesh sieves;

[0057] (2) Accurately weigh the mannose, cyclamate, and hydroxypropyl methylcellulose of the prescribed amount respectively, pass through a 120-mesh sieve respectively, and mix them uniformly in equal increments;

[0058] (3) Steps (1) and (2) are mixed in equal increments to obtain a mixed powder;

[0059] (4) Add 2 g of 50% ethanol to the mixed powder to make a soft material, and pass through a 30-mesh sieve;

[0060] (5) Dry at 80°C, granulate with a 30-mesh sieve;

[0061] (6) After the intermediate is qualified, the finished product can be obtained by sub-packaging.

Embodiment 3

[0063] Enramycin 4g

[0064] Sorbitol 65g

[0065] Ansai K 25g

[0066] Polyvinylpyrrolidone 5g

[0067] Propylene glycol 1g

[0068] The preparation method is as follows:

[0069] (1) Accurately weigh the prescribed amount of enramycin and pass through a 100-mesh sieve;

[0070] (2) Accurately weigh the sorbitol, sulfame potassium acetate, and polyvinylpyrrolidone of the prescribed amount respectively, pass through a 100-mesh sieve respectively, and mix uniformly in equal increments;

[0071] (3) Steps (1) and (2) are mixed in equal increments to obtain a mixed powder;

[0072] (4) Add propylene glycol to the mixed powder to make a soft material, and pass through a 35-mesh sieve;

[0073] (5) Dry at 70°C, granulate with 35 mesh sieve;

[0074] (6) After the intermediate is qualified, the finished product can be obtained by sub-packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com