A multi-mode microwave heating chamber for processing heap leached uranium ore

A microwave heating cavity and uranium ore technology is applied in the field of heating cavity to achieve the effects of uniform energy density, small microwave leakage and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

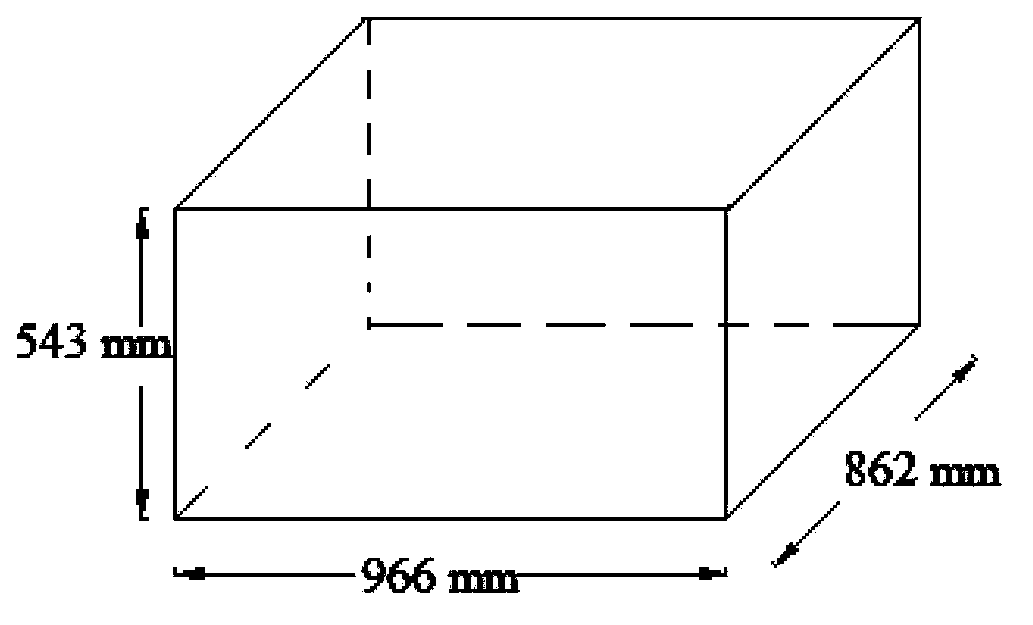

[0022] Embodiment 1: A multi-mode microwave heating cavity applied to a microwave treatment system for heap leaching uranium ore, which includes a power feed port 1, an illumination port 2, an operation window 3, a moisture discharge port 4, a waveguide 5, and a magnetron 6 and the material cavity 7, wherein there are 15 power feed ports and wave guides respectively, and the power feed port 1, the lighting port 2, the operation window 3, the dehumidification port 4, the wave guide 5 and the material cavity 7 are all made of stainless steel. The entire microwave heating cavity is a cuboid, and its dimensions are: length × width × height = 966 mm × 862 mm × 543 mm.

[0023]The 15 power feed ports 1 are all located on the top of the cavity, and are distributed in an area of 966 mm×862 mm. The size of each power feeder is 80 mm×60 mm, the power feeder serial numbers are 1.1, 1.3, 1.5, 1.7, 1.9, 1.11, 1.13, 1.15 are longitudinal openings, and the power feeder serial numbers are 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com