Method for determining microstructure of lipid microsphere/lipid emulsion

A lipid emulsion and microstructure technology, which is applied in the preparation of test samples and material analysis by measuring secondary emissions, can solve the problems of sample damage, low success rate, and poor reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

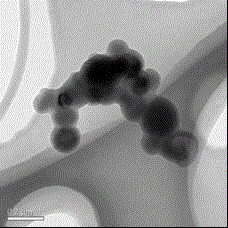

[0033] Sample: alprostadil injection (trade name Kaishi), negative dye: phosphomolybdic acid, dilution ratio: about 2500 times, negative ion generator is Stablo remover from Shimadzu company, drying method is vacuum decompression drying, test The result is as Figure 5 shown.

Embodiment 2

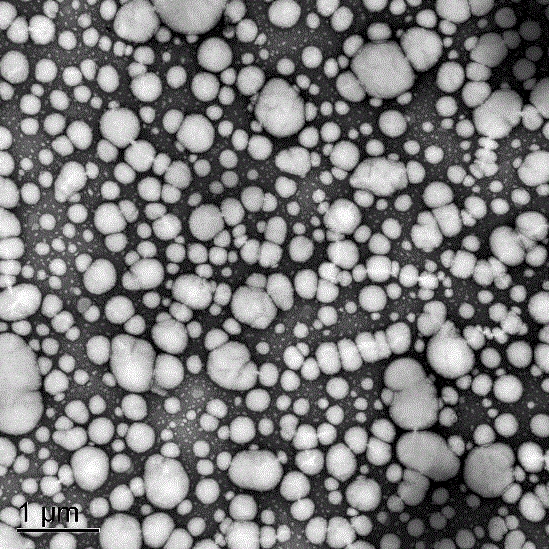

[0035] Sample: Flurbiprofen axetil injection (trade name Kaifen), negative dye: phosphotungstic acid, dilution ratio: about 1000 times, negative ion generator is ANTIST-KIT-UN antistatic device from Mettler, Germany, dry The method is vacuum drying under reduced pressure, and the test results are as follows: Image 6 shown.

Embodiment 3

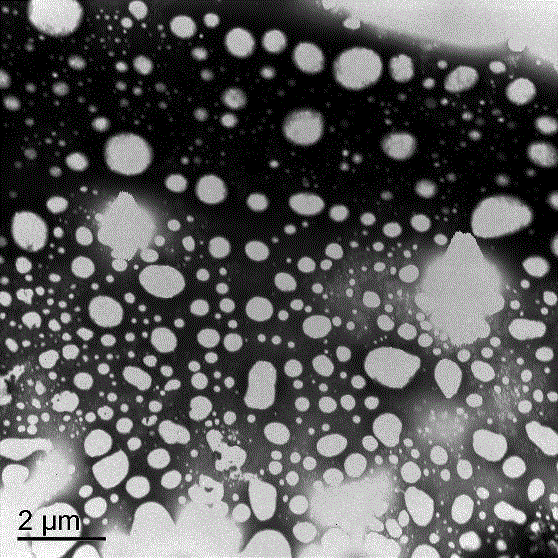

[0037] Sample: fat emulsion injection (trade name Intralipid), negative dye: uranyl acetate, dilution ratio: about 4000 times, negative ion generator is YSTP01 antistatic pen, drying method is infrared lamp drying, the test results are as follows Figure 7 shown.

[0038] Depend on Figure 5 , 6 7. It can be seen that in the three commercially available samples measured by the method of the present invention, the microparticles of the lipid microspheres / lipid emulsion are round, clear, and have good separation, the microscopic morphology is clear, and there is no aggregation and adhesion, and the repeatability of multiple determinations is it is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com