Novel high-performance cooperative system flame retarding asphalt

A high-performance, modified asphalt technology, applied in the field of flame retardant materials, can solve the problem of limited application, and achieve the effects of reducing production costs, reducing flammability, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

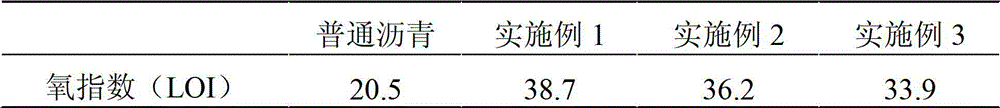

Examples

Embodiment 1

[0035] Example 1: 100 kg of coal tar pitch, 4 kg of powdered styrene-butadiene rubber, 24 kg of organosilicon flame retardant, 16 kg of stearate and potassium silicate, 12 kg of catalytic cracking oil slurry and heavy deasphalted oil, and 4 kg of zinc borate. Add coal tar pitch, powdered styrene-butadiene rubber, catalytic cracking oil slurry and heavy deasphalted oil into a high-speed shearer and stir for 14 hours at a temperature of 165 ° C, with a rotation speed of 4000 rpm; then, under the same temperature and stirring conditions, the Silicone flame retardant, stearate, potassium silicate and zinc borate were added to the high-speed shearer at a constant speed within 5 minutes and continued to stir for 5 hours. After cooling at room temperature, a synergistic flame-retardant asphalt was obtained.

Embodiment 2

[0036] Example 2: Shale asphalt 100kg, powdered styrene-butadiene rubber 3kg, organosilicon flame retardant 18kg, dibasic lead phosphite and tribasic lead sulfate 11kg, solvent refined extraction oil and naphthenic oil 9kg, zinc borate 3kg. Add modified shale asphalt, powdered styrene-butadiene rubber, solvent-refined oil and naphthenic oil into a high-speed shearer and stir for 10 hours at a temperature of 150°C at a speed of 3500rpm; then under the same temperature and stirring conditions, The organic silicon flame retardant, dibasic lead phosphite, tribasic lead sulfate and zinc borate were added to the high-speed shearer at a constant speed within 5 minutes and continued to stir for 4 hours. After cooling at room temperature, the synergistic system flame-retardant asphalt was obtained.

Embodiment 3

[0037] Example 3: 100 kg of coal tar pitch and petroleum pitch, 2 kg of powdered styrene-butadiene rubber, 10 kg of organic silicon flame retardant, 7 kg of calcium carbonate, 5 kg of white oil and coal tar fraction, and 2 kg of zinc borate. Add coal tar pitch, petroleum pitch, powdered styrene-butadiene rubber, white oil and coal tar fractions into a high-speed shearer and stir for 6 hours at a temperature of 140 ° C, with a rotation speed of 2500 rpm; then, under the same temperature and stirring conditions, the The silicone flame retardant, calcium carbonate and zinc borate were added to the high-speed shearer at a constant speed within 5 minutes and continued to stir for 3 hours. After cooling at room temperature, the synergistic system flame-retardant asphalt was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com