Method for manufacturing recombined bamboo decorative material

A technology for decorative materials and bamboo and wood, applied in the field of manufacturing reconstituted bamboo and wood decorative materials, can solve the problems of single color of reconstituted bamboo, low lateral strength, high density, etc., and achieves strong promotion and application value, high lateral bonding strength, and dimensional stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

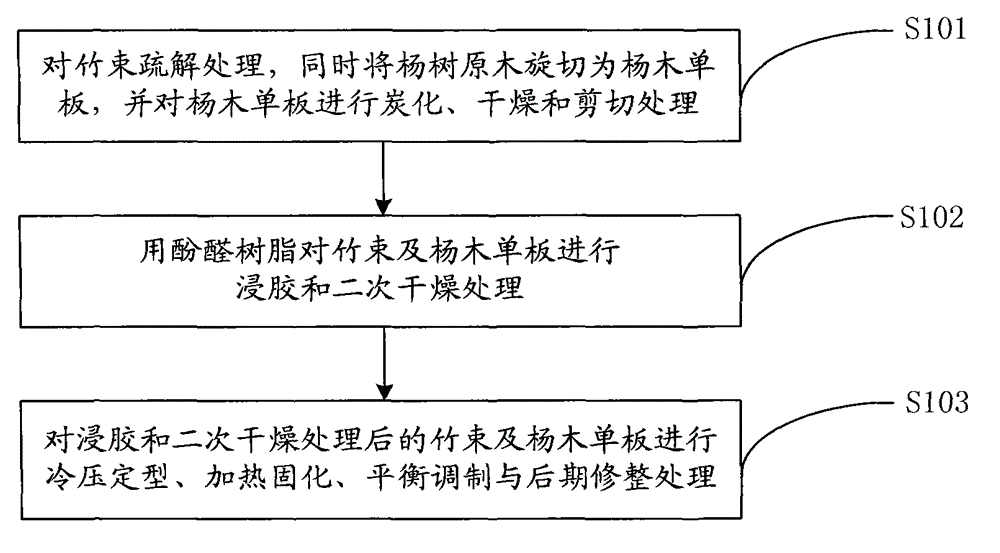

Method used

Image

Examples

Embodiment 1

[0054] (1) The moso bamboo is decomposed into bamboo bundles with a length of 1000mm and a width of 20mm by using bamboo rolling equipment. Then adopt the conventional kiln drying method to dry the natural color bamboo bundles to a moisture content of 10%;

[0055] (2) Process poplar logs with a length of 1000mm into string-cut veneers with a thickness of 2.0mm by using a string cutting machine, stack the string-cut veneers neatly, and put them directly into a high-temperature and high-pressure treatment tank after being loaded on a wood car. Use the saturated water vapor supplied by the boiler to carbonize the string-cut poplar veneer, control the pressure of the water vapor in the treatment tank at 0.35MPa, carbonize the veneer for 2.5 hours, and carbonize the veneer to brown;

[0056] (3) Use a mesh belt dryer to dry the carbonized poplar veneer to a moisture content of 12%, and then use a veneer shear to cut along the longitudinal direction of the veneer along the grain to...

Embodiment 2

[0066] (1) Adopting bamboo material rolling equipment to decompose moso bamboo into length 1920mm, width is 25mm bamboo bundle, then adopts conventional kiln drying method to dry natural color bamboo bundle to moisture content of 12%;

[0067] (2) Process poplar logs with a length of 1920mm into string-cut veneers with a thickness of 2.5mm by using a string cutting machine, stack the string-cut veneers neatly, and put them directly into a high-temperature and high-pressure treatment tank after loading them on a wood car. Use the saturated water vapor supplied by the boiler to carbonize the string-cut poplar veneer, control the pressure of the water vapor in the treatment tank at 0.4MPa, carbonize the veneer for 1.5 hours, and carbonize the veneer to brown;

[0068] (3) Dry the carbonized poplar veneer to a moisture content of 10% by conventional kiln drying method, and then use a veneer shear to cut along the longitudinal direction of the veneer along the grain, and cut the pop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com