Method for air-tightly welding shell and cover plate of microwave component

A microwave component and hermetic sealing technology, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of circuit module failure, circuit performance reduction, and corrosion of circuit solder joints, so as to improve reliability and life, and improve Airtight qualified rate and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

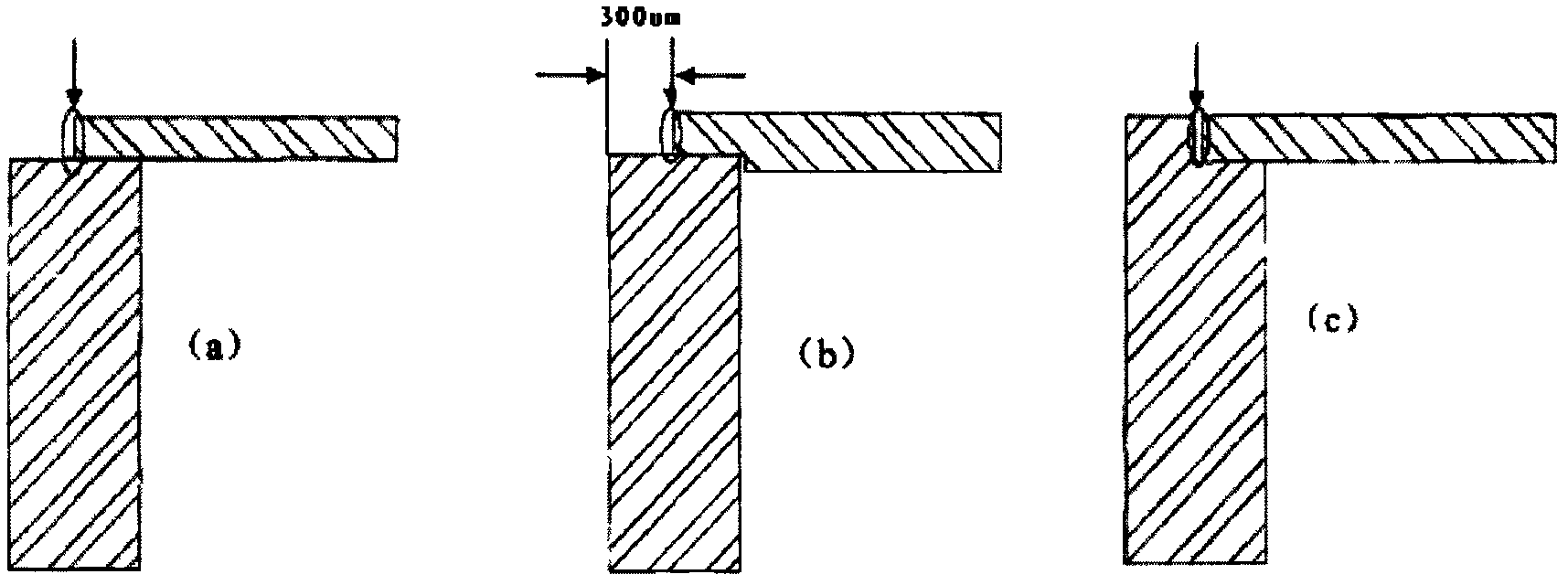

[0014] The technical solution adopted by the invention to solve its technical problems is to provide a sealed microwave component aluminum alloy shell. In the joint form of seal welding, the seal welding is carried out in a glove box filled with Ar, and a magnetic clamp is used during welding, and the magnetic base of the magnetic clamp and the pressing block attract each other.

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

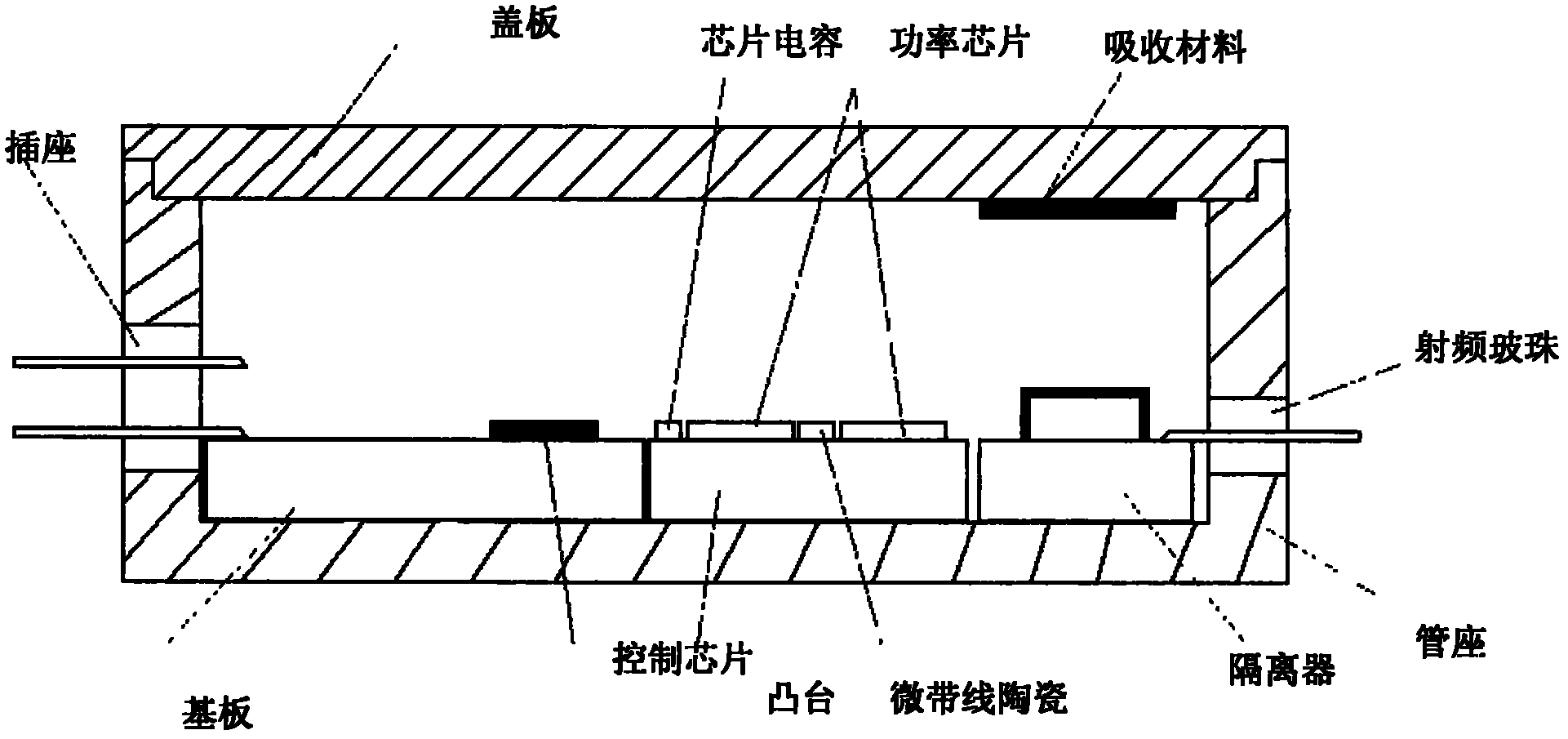

[0016] Such as figure 1 Shown is the structural composition of microwave components. Generally, the shell of microwave components is in the shape of a square box, which is composed of a shell, an internal microcircuit, a protective gas in the cavity and a cover plate, as well as glass beads for signal input and output, and for power supply. The supplied socket, the seal between these connectors and the housing is generally sealed by soldering before the microwave co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com